Debrief: Hyper-X

Scramjet power? Simple: Keep a match lit in a 7,000-mph wind.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/hyper-388-jul05.jpg)

IT WILL NEVER HANG IN THE SMITHSONIAN, because it ended up on the bottom of the Pacific Ocean. Its pilots will not enjoy ticker tape parades; they were all on the ground, watching the computer-operated craft on video screens. But in about 10 seconds, a combination of scientific persistence and untested technology constructed of leftovers from secret military projects changed how we define “fast.” The little black wedge called the X-43A, smaller than a Ferrari, flew faster than any air-breathing airplane ever—nearly 10 times the speed of sound, and at about two miles per second, swift enough to cross the country in 20 minutes. It owes its tremendous speed to a jet engine that has no moving parts; in fact, it seems nothing like an engine, and some scientists doubted it could ever work.

For proponents of the engine known as a scramjet—short for supersonic combustion ramjet—the brief flight offered the same sort of vindication the Wright brothers earned in 1903 at Kitty Hawk: The project rebounded from a catastrophic failure of the first X-43A flight in 2001, when a booster carrying the airplane careened out of control. And the flight finally turned the experimentalists’ concept into reality, a result of five decades of research aimed at producing a hypersonic jet engine that could propel airplanes nearly into space and back again more cheaply and safely than rockets.

“It was the Holy Grail, if you will,” says Anthony Castrogiovanni, the X-43A propulsion team leader at Alliant Techsystems, the NASA contractor that engineered it. “A successful flight was going to change the way the world thinks about hypersonics.”

There’s fast, there’s supersonic, and then there’s hypersonic—more than five times the speed of sound, a realm rarely probed by airplanes because few can survive it. Scramjets are the only engines other than rockets that can reach hypersonic speeds. Their first use would likely be by military forces, as light and adaptable engines for ultra-fast and maneuverable missiles. But they are such a temperamental blend of speed, flame, and fuel that any vision of passenger-carrying scramjet-powered airliners crisscrossing the skies remains a distant one. “It’s a very simple concept that’s very complicated to pull off,” says Vince Rausch, manager of NASA’s Hyper-X program, parent of the X-43A.

The first of three X-43A flights was set for June 2001. A winged Pegasus rocket modified to boost the 12-foot-long, five-foot-wide research craft to its planned altitude and speed dropped like clockwork from the wing of a NASA B-52 mothership over the Pacific Ocean northwest of Los Angeles. After five seconds the Pegasus’ solid rocket motor ignited in a blaze. But eight seconds later, as the rocket neared the speed of sound, its right fin tore off, then the left fin, rudder, and wing. The 49-foot rocket tumbled wildly in a smoky blur until a Western Test Range safety officer triggered onboard explosives to destroy it. The X-43A aircraft attached to its nose never had a chance.

For Griff Corpening, an engineer at NASA’s Dryden Flight Research Center in California, and others who had shepherded the project for some five years, the failure felt like a kick in the gut. “People look at science and technology as dry stuff, but I wish they could understand all of the rush of emotions that you feel,” he says. At least the failure had been the rocket’s, not the scramjet’s. An investigation determined that the Pegasus rocket was too far out of its element. Orbital Sciences had designed the launch vehicle to be released from an airplane at 40,000 feet and to loft satellites into orbit. But this time it was released 20,000 feet lower, where the air is denser. Computer models based on data from earlier Pegasus flights predicted the craft’s fins and rudders could handle the denser air.

The project team members were buoyed by one batch of data, though: The little X-43A held together even as the out-of-control rocket whipped it every which way. “It told us we had one heckuva solid vehicle,” says Ted Rothaupt, an engineer at Boeing Phantom Works, Boeing’s advanced research and development branch, which helped develop the X-43A. The X-43 looked tough enough for hypersonic flight—if only it could get there.

As long as humans have flown, they have longed to fly faster. Most members of the X-43 team are all about speed. When Paul Reukauf, deputy project manager for the X-43A at Dryden and a pilot himself, heard that fellow scientist Chuck McClinton had bought a boat, he had only one question: “Why would anyone spend that amount of money to go six knots?”

Rockets have always outpaced airplanes. They accelerate by rapidly combining fuel with oxygen they carry on board. The drawbacks are that liquid oxygen is heavy and hard to handle.

Because the oxygen tanks are so weighty and take up so much space, they reduce the rocket’s payload-carrying capacity. And that’s one reason why the cost of firing something into space is about $10,000 per pound. Speed is even pricier. The faster a rocket must go, the more fuel and oxygen it needs—in other words, still more tankage. The craft gets heavier and heavier, eventually reaching a point where it simply cannot carry enough fuel and oxygen to go any quicker.

But jet engines can get oxygen from the air. Without oxygen tanks, the craft suddenly gains up to five times more room for payload, it picks up speed, and it costs less to fly. In common jet engines, like the ones on commercial airplanes, rotating blades compress incoming air. Injected fuel mixes with the air and burns. The hot gases turn a turbine to drive a fan and compressor, then expand out the rear nozzle, propelling the airplane.

The trouble with conventional jets is that they have a built-in speed limit. When they approach Mach 4, or four times the speed of sound, the air is arriving faster than they can swallow it. Drag caused by the engine and airplane moving through the air cannot be overcome by the engine’s propulsion. And the friction of the air at that speed heats the engine until it begins to melt.

These dilemmas are compounded by the powerful force of shock waves. An airplane flying faster than sound outruns its own sound waves, which then attach like the wake of a boat to the airplane’s nose and tail. These wakes are the shock waves bystanders on the ground hear as a ba-boom. Closer to the airplane, shock waves are much more intense. NASA learned early on that shock waves can be very fickle—and very dangerous.

A final goal of the X-15, the experimental rocket-powered NASA aircraft that broke speed and altitude records through the 1960s, was to test a new design for a scramjet like the X-43A’s. In 1967 engineers at Dryden fitted beneath the X-15 a mock version of the engine to study the aerodynamics at Mach 7. Neither pilot William “Pete” Knight nor anyone else knew it during his flight, but unexpectedly strong shock waves trailing the dummy engine as Knight reached Mach 6.7 interacted with other streams of air and began cutting into the aircraft like a scalpel heated to 3,000 degrees. Explosive bolts meant to jettison the engine prior to landing detonated early, and the jet fell off. Heat ripped into the X-15’s underbelly, and instruments started going dead. Knight set down just before the fuselage disintegrated.

Test pilot William Dana, serving as mission controller at the time, saw the X-15 riddled with holes, and “my knees started shaking,” he recalls. “It looked like a maniac had gone wild with a cutting torch and had a field day.” NASA cancelled further airborne scramjet tests, and that X-15 never flew again. “We fried the airplane so badly we decided it was better done in a wind tunnel,” Dana says.

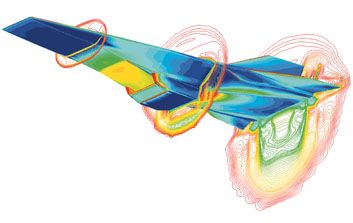

The faster a jet goes, the simpler its design must be. To keep heat from building up, the aircraft must have no parts that slow the air and bounce shock waves around. The solution? Get rid of the compressor blades and other rotating pieces. For hypersonic flight, engineers approached airplane design in a whole new way. Instead of fans mechanically compressing air sent to the tunnel-like engine combustion chamber, the bow of the airplane plows into and compresses air, funneling it into the chamber; here, the airplane body forms part of the engine.

“What you have is a flying engine,” says McClinton, technology manager for the Hyper-X. When the supersonic speed of the airplane rams oncoming air into the combustion chamber, the engine is called a ramjet. But that works only at very high speeds. The SR-71 Blackbird, for example, has turbojets with afterburners to accelerate and cruise at supersonic speed. When the aircraft is flying fast enough to compress the air on its own, its engines remake themselves. Ducts direct part of the airstream around the rotating compressors, and the engines become ramjets that propel the airplane to Mach 3 or higher.

But ramjets, like turbojets, slow the air to subsonic speed before combining it with fuel. This minimizes formation of troublesome shock waves, but it works only up to about Mach 6. Any faster and the engine begins to melt from the effort to slow all the air down. That’s when a scramjet becomes the only option. As the air races through the engine, it is moving at supersonic speeds and generating shock waves. But a scramjet uses the shock waves to advantage.

Picture a river with banks lined with concrete. The banks reflect waves and boat wakes in the water. A scramjet combustion chamber does much the same with shock waves. On the ground, you could peer into it and it would look like an empty pipe. But once moving beyond the speed of sound, its internal design and shape orient shock waves into a precise pattern. It directs, compresses, and focuses the airflow, creating the right temperatures and pressures for combustion. A scramjet fashions the essential components of a jet engine from the air currents racing through it. Joel Sitz, NASA’s X-43A project manager at Dryden, shrugs and says: “You’re training the air to do tricks.”

The X-43A’s combustion chamber measures about three feet in length, so at a top speed of 7,000 mph, air whips through it in roughly .001 second. That’s not much time for fuel to mix with oxygen, ignite, and burn. Engineers liken the challenge to keeping a match lit in a tornado—but more difficult. If fuel burns too fast, the airflow inside the engine reverses, causing power loss—an “unstart,” in jet jargon. If it burns too slowly, it’s as if your car’s gasoline were igniting a block behind you. All its energy goes to waste.

But in the mad rush of air, the shock waves form a kind of shelter, as you would with your hands to light a candle in the wind. Into the eye of this storm, the X-43A’s engine injects hydrogen fuel and ignites it with silane, a silicon gas that instantly burns on contact with air.

For the better part of 50 years, scramjets were more theory than reality. It’s impossible to thoroughly test them in laboratory wind tunnels; even the fastest tunnels can produce scramjet airspeeds only in brief pulses. They provided split-second snapshots, but never a moving picture of a scramjet in continuous flight. Some doubted a scramjet could ever produce enough power to overcome the drag of air hitting any airplane at over Mach 7, no matter how sleek and aerodynamic.

But if it could, it would enable production of a jet fast and powerful enough to do much of the hard work of reaching space. Because a scramjet must move at Mach 6 or 7 to ignite, it needs a booster to take off and accelerate, but the rocket could be much smaller. A scramjet-rocket combo could carry the same payload as the space shuttle, but weigh only a quarter as much. That reduction could cut the cost of putting a pound in orbit by perhaps 80 percent, although some engineers say the research cost to develop the scramjet could cancel any gains.

President Ronald Reagan believed. In his 1986 State of the Union speech, he announced “a new Orient Express that could, by the end of the next decade, take off from [Virginia’s] Dulles Airport, accelerate up to 25 times the speed of sound, attaining low Earth orbit or flying to Tokyo within two hours.” He was invoking the National Aerospace Plane, a NASA outgrowth of a highly classified military project to develop a reusable, scramjet-driven aircraft that could take off from the ground and accelerate into space or travel between continents. Though NASA called it the X-30 and a successor to the space shuttle, it got its billions in funding from the military. Invoking the image of an airplane that could race in and out of enemy airspace before it could be detected and shot down may have been mostly cold war intimidation, though, because by the 1990s the military lost interest and Reagan’s vision never flew.

Instead, it became the X-43A. The razor-like X-43A is the spitting image of the National Aerospace Plane, but less than a tenth the original size. A 1995 NASA competition made it next in the line of experimental X-planes. The details of its engine chamber remain highly guarded by the military—so much so that while it’s on the ground, padlocked covers on both ends of the chamber shroud it from anyone without clearance. Its scaled-down size was matched to a mission that was narrowed to focus on one basic goal: Prove a scramjet can power an airplane, and do it quickly and cheaply.

That meant keeping it simple. The X-30 was to have a human crew; the X-43A would be automated. It would fly only as long as it took to burn the hydrogen fuel it could carry. Engineers thought about trying to land it on the Navy’s San Nicolas Island, off the coast of California, but gritted their teeth and decided it would be simpler for it to transmit data and ditch in the ocean.

The SR-71 lifts off with a turbojet before accelerating to ramjet mode. The National Aerospace Plane was also intended to shift gears in flight. The X-43A had to rely on a Pegasus rocket to get up to speed.

That raised a question: How do you push the 3,000-pound X-43 off a rocket going thousands of miles an hour? Earlier scramjet experiments in Australia and Russia had attached scramjets to rockets to prove the engine would function at high speeds. They did not try to power an airplane with it. The X-43A had to leave the rocket and fly on its own. Finally engineers found a technology to push the two apart fast enough so that they would not collide: the piston system that B-1 bombers use to eject bombs.

The X-43A was packed to the gills with instruments, fuel lines, and controls. Its budget did not allow for miniaturizing, and its size wouldn’t allow for backup systems. Technicians shaved its battery to the hundredths of an inch. “There was no room to drop a marble inside,” says Castrogiovanni.

Everything was enclosed within a body that would endure the highest temperatures and pressures an airplane had ever faced. Stainless steel and carbon fibers formed the wings’ leading edges, sharpened like razor blades. The aircraft’s nose was made from an enormous piece of tungsten to take the heat and balance the heavy back end of the aircraft. Its engine chamber was crafted from copper and cooled by water lines to control temperatures not much lower than those on the surface of the sun. Its fuselage was covered with the same sort of thermal tiles that cover the space shuttle. But instead of crafting each tile to precise dimensions, as NASA does for the shuttle, X-43A designers kept costs down by first cementing the tiles in place and then machining them to a smooth surface.

Even the airplane’s fins were designed with a small gap so that when they expanded from the heat of high-speed flight, they would not bind with adjacent parts. Designers were careful not to make the gap too large, though, or the airflow would become turbulent and slow the vehicle down.

To avoid another catastrophe, engineers beefed up the Pegasus’ fins and rudders and removed 3,300 pounds of the rocket’s propellant. By eliminating some fuel, the engineers could launch at the higher, thinner altitudes the rocket was designed for without worrying that it would loft the X-43A too high.

On March 27, 2004, the second X-43A took to the sky. This time it stayed on course. When it hit 95,000 feet, the bomb pistons fired with 10,000 pounds of force. The aircraft was finally on its own and flying. Within 2.5 seconds, the engine door opened, the train of shock waves instantaneously lined up inside, the silane ignited the hydrogen, and, for the first time, a scramjet was accelerating on its own. The engine burned for 11 seconds, propelling the X-43 to Mach 6.86. It bested the previous air-breathing speed record—just over Mach 5, set by a ramjet-powered missile—and outdid the airplane speed record, Mach 6.7, set by the X-15.

Eight months later, an X-43A fine-tuned for even higher speeds ran its engine for 10 seconds, shooting to a record-breaking Mach 9.8 on November 16, 2004. About 500 sensors transmitted temperature, pressure, strain, and other readings back to NASA, providing hundreds of times more information than the most elaborate wind tunnel test ever could.

After its engine stopped, the X-43 coasted through a sequence of maneuvers to reveal more about its aerodynamics. One signal suggested it may have started melting on its way down.

Researchers will be crunching the data for years, but they already know a few things. One is that they have the workings of scramjets well figured out: The X-43A’s performance came very close to their predictions. Another is that flying a scramjet for much longer than 10 seconds will demand a far more sophisticated cooling system and revolutionary new materials to handle the intense heat.

The X-43A’s fleeting glimpse into the future may also be the last for a long time. NASA has shifted focus to President Bush’s moon-Mars exploration initiative, carving aeronautics research down to just five percent of its newest budget. There is now almost no money for hypersonics. Engineers have transferred to other projects, and Chuck McClinton is sending wind tunnel models and other stepping stones in scramjet science to the Smithsonian.

“We’re going to be [part of] history,” he says. “It’s like many technology demonstrations. You’ve proven it works. Now you’re done.”

Contractors are lobbying Congress to continue work on the X-43C, a sibling of the original but powered by more easily handled hydrocarbon fuel, and the military continues modest hypersonic research under such programs as the Falcon project, co-sponsored by the Defense Advanced Research Projects Agency and the U.S. Air Force. But without a national effort, it’s unlikely to get very far, McClinton says. The scramjet, not quite rocket or jet, may end up retreating to the shadows.

For 10 seconds, though, it was way out in front.