The Electric Airplane

Quiet, smooth, dependable—shouldn’t we be flying these by now?

It’s just 55 miles from my home airport in Los Angeles to the Tehachapi gliderport where Pete Buck has his hangar, but it’s usually a jarring flight through torrents of wind that tumble eastward off the mountains like whitewater. Not today. The air is perfectly still. The hundreds of huge windmills that dot the ridges are motionless, the sky is without clouds, the visibility without limit. I’ve pulled the rpm way back, so that the grumble of the engine, through earplugs and a headset, recedes into the distance. The airplane seems to slide along frictionlessly, like a skater coasting, hands in pockets, on a pond of infinite blue.

An engineer with a youthful manner and a day job at the Lockheed Martin Skunk Works, Buck, 51, is waiting on the ramp when I taxi in. As we walk to his hangar, only our voices, and the occasional chirp of a bird, disturb the universal calm.

I’ve come to talk with Buck about a novel airplane he’s developing. It’s an electric airplane—common enough in RC modeling, but still an oddity in the passenger-carrying world. Electric flying is going to be something like my flight this morning: not trying to get somewhere far off in a hurry, but just the beautiful sensation of being suspended in the air, of flight for its own sake. It’s often said that every great advance in aviation begins with a new kind of engine; I suppose that putting electric motors into airplanes is such an advance, but in a somewhat backward direction: toward lower power, slower airplanes, less noise and stress, and a return to those jolly early days when merely to rise up into the air made you feel like some sort of god.

Electric flight goes back surprisingly far. In the 1880s a couple of French army officers named Renard and Krebs gave a hydrogen-filled dirigible, La France, huge batteries and an 8-horsepower electric motor that enabled it to do what no balloon had done before: return to its launch site at the end of a flight.

After that early triumph, however, all went quiet on the man-carrying electric-aircraft front and remained so for about 90 years. The current renaissance began with Robert Boucher, who pioneered the use of electric motors for model airplanes and in the early 1970s built a couple of pilotless solar-powered aircraft under contracts with the Defense Advanced Research Projects Agency. In 1979, the late Paul MacCready, whose Gossamer series of human-powered airplanes had brought him international fame, began working with Boucher. MacCready’s company, AeroVironment, first tested an electric version of the piloted Gossamer Penguin, then went on to build Solar Challenger, whose two tandem wings were covered with more than 16,000 solar cells. Boucher’s company, AstroFlight, whose principal business today is miniature motors and related gear for RC modelers, supplied the five-horsepower motor. Solar Challenger had no batteries; it collected sufficient energy from sunlight—4,400 watts—to take off, climb to 14,000 feet, and cruise at 40 mph. In 1979 it made a five-hour, 170-mile flight across the English Channel, consuming no fuel whatever. Today it resides, deservedly, in the Smithsonian.

AeroVironment later built a series of ever-larger, unmanned solar-powered airplanes, culminating in the 247-foot, 14-motor flying-wing Helios, which, when it flew, resembled a phalanx of semi-inflated air mattresses bobbing on rough water. The eventual aim of the project was to circle for days as a sort of low-level observation or communications satellite, collecting and storing sufficient energy during daylight hours to sustain itself through the night. AeroVironment was never quite able to achieve that goal; the latest iteration in its long-running quest for “eternal flight,” Global Observer, is powered by a hybrid system in which a highly efficient hydrogen-burning reciprocating engine drives a generator that in turn powers four electric motors. It is expected to be able to remain aloft for five days, in part because hydrogen has three times as much oomph, per pound, as gasoline. But the idea of an airplane that consumes no fuel continues to intrigue experimenters and adventurers; in Switzerland, one team has just crossed the Alps on solar power alone, and another has announced plans for an airplane, Solar Impulse, that is intended to circle the globe.

When Pete Buck “started poking at an electric airplane,” as he puts it, he visited the same man Paul MacCready turned to: Robert Boucher at AstroFlight. “He mentored me in the design of the motor,” says Buck, who, besides working at Lockheed Martin, is the chief engineer of Sonex, an Oshkosh, Wisconsin aircraft kit manufacturer. Buck and Sonex founder John Monnett are working on an electric conversion for one of the company’s kits, an aluminum, V-tail two-seater called Waiex (pronounced “Y-X”). Replacing a gasoline engine with an electric motor and some batteries sounds like a simple matter—those are familiar technologies, after all—but it turns out to be harder than it looks.

The project began a decade ago, when Buck and Monnett tossed around a whimsical idea for an electric airplane they called Flash Flight. It would have stayed aloft for 10 minutes on a bunch of D cells, and might have had potential for an ad campaign. Today, Buck dismisses it: “We finally decided it was silly, and it wouldn’t work anyway.” But he had caught the electric bug. He and Monnett outlined a more ambitious project: a genuine airplane, one that could stay aloft at least 20 minutes and, preferably, an hour and a half.

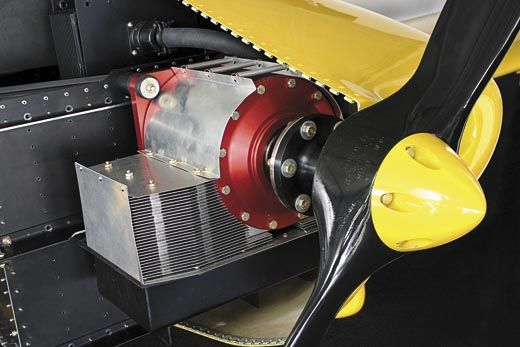

Their electric motor, a small cylinder bristling with cooling fins, is typical of the class of motor suitable for aviation: a 270-volt, 72-hp brushless DC unit with samarium-cobalt rare-earth magnets—the kind you would need a chisel to pry off your refrigerator door.

Magnetic forces—attraction and repulsion—cause the rotor (an electromagnet) of an electric motor to spin. Some types use two metal tabs, or brushes, with opposite charges; during each revolution, the rotor comes into contact with first one brush, then the other, each time switching its polarity. To perform the same function, a brushless electric motor relies on a solid-state switching device called a controller. Rapid switching of high-voltage currents, however, turns out to be difficult. The currents have momentum, just like moving water, and a random surge can quickly vaporize even quite massive transistors. Another problem is more mundane: The motors are hard to start.

“The controller is really where it’s at,” Buck says. “It should be cookbook, but it’s not that easy. None of us recognized the complexity. There are only a few people who know how to do it, and they aren’t talking.”

The battery pack consists of a stack of thin lithium-polymer cells that resemble foil-wrapped legal pads. “We always thought the batteries would come to us,” Buck says—meaning that they sized the airplane and motor for batteries that didn’t yet exist. “There are batteries out there that have five times the energy density of those we can buy today, but they’re only in the lab.” And the Sonex team wanted the electric airplane to be comparable in price to the aircraft now being built from the Waiex kits. “We’ve always believed in an airplane that would be available at a price the average pilot could afford,” says Buck, “so that the whole airplane, including the engine, would cost about the same as a new car, around $26,000.”

Batteries are, in the final analysis, the key to the whole project. Controllers are tricky but feasible; motors are delicate and expensive, but technically straightforward. It’s really on batteries—developing ones that are powerful, durable, and not prone to burst into flame if mistreated—that the future of electric airplanes hangs.

A gasoline powerplant, with its fuel, accounts for about a quarter of an airplane’s takeoff weight. An electric powerplant is somewhat heavier to begin with; it adds 75 pounds to the weight of the Waiex because the batteries alone weigh 200 pounds. The big disadvantage is that the energy available from all those batteries is equivalent to only a couple of gallons of gasoline. Observes Buck: “We pilots would consider that ‘unusable’ ”—the technical term for dregs in the bottom of the fuel tank that may not be available in all flight attitudes.

Buck aims at an airplane of conventional dimensions—with a little more wingspan than most, but able to be tucked comfortably into an ordinary hangar—and having climbing and cruising capability comparable to that of a gasoline-powered airplane in every respect except, perhaps, duration of flight. In other words, he and Monnett want to prove that an electric airplane can look and fly just like a gas-powered one.

Greg Cole sees things a little differently.

Cole, 46, is a freelance aeronautical engineer. His Oregon company, Windward Performance, produces a carbon-fiber sailplane called the SparrowHawk, which, at 155 pounds empty, weighs less than many of the pilots who fly it. Cole is a bit of a visionary. He is concerned not just about the price of gasoline, but also about aviation as a whole—the possibility that the cost and the complexity and stress of flying modern airplanes might drive people away from flying. He is not just an engineer; he is a reformer. Cole, like Monnett, is preparing to manufacture an electric two-seater. The wingspan of his design is a glider-like 51 feet—a rather cumbersome size for taxiing, parking, and hangarage at many general-aviation airports. The longer an airplane’s wingspan, though, the less power it needs to lift a given weight. Cole’s motor, similar in design to Buck’s but smaller, is rated at just 40 hp. If he can keep his airplane’s empty weight below 500 pounds or so—the SparrowHawk demonstrates his ability to engineer very light, yet strong structures—he will be able to climb at 660 feet a minute and cruise at 70 mph on the electrical equivalent of one gallon of gas per hour. “We need to get into lower-power airplanes,” he says. “We need to do smaller.” He brushes aside objections that his design will not mesh easily with existing infrastructure. Electric—smooth, quiet, non-polluting, and with motors that will never fail or wear out—is “a completely viable way to revolutionize aviation.”

The aviation he is talking about is recreational: “I’m not looking beyond two seats.” His airplane will cost $50 an hour to operate; $30 of that is a reserve for replacing the battery pack after 500 to 1,000 charging cycles. Because the airplane itself has very low drag and is highly efficient, the cost of the electric “fuel” is negligible. Cole’s ultimate vision of sustainability is right out of the Whole Earth Catalog: A couple of small wind-powered generators on the roof of a hangar would, with sufficient wind, provide power for one or two flights a week. In a pinch, he concedes, “You could always top off from [an electric socket in] the wall.”

Cole has made little effort to publicize his project; Monnett, on the other hand, announced his “E-Flight Initiative” in 2007 at the Experimental Aircraft Association’s annual Oshkosh fly-in and displayed a mockup of the new powerplant. But a 59-year-old retired jeweler and self-taught engineer from New Jersey, Randall Fishman, stole a march on both Monnett and Cole. In 2008 Fishman, whom his friends used to call Doctor Gizmo, flew his single-seat electric airplane in front of cheering crowds at Oshkosh. The airframe is a discontinued Moni motor glider (built from a kit designed, coincidentally, by John Monnett before he started Sonex), modified and refitted with an 18-hp electric motor. It can cruise at 70 mph, using just 6 hp to stay aloft. A 90-minute flight consumes 5.6 kilowatt-hours of electricity—about 70 cents’ worth, at present rates. It recharges from a wall outlet in six hours.

“I used to like to fly ultralights, but they were powered by Rotax snowmobile engines,” Fishman says. “They were so loud. And after you flew for a while and landed, your body would still be vibrating.” In his pursuit of quiet, vibration-free flight, Fishman has been honored by the EAA, which recognized his contribution to light aircraft design with the 2008 August Raspet Award. (John Monnett is a previous winner, as is Pete Buck, though not for their work in electric power.) And this year the Lindbergh Foundation awarded him a $10,580 grant.

Like the Wright brothers, Fishman started with a bicycle. He used to have to pedal uphill to get to his jewelry store, and he didn’t want to arrive sweaty. When he saw an ad for an electric bicycle motor, he thought: That would be nice. More than 20 years, hundreds of thousands of dollars, and several electric conveyances—a scooter, an ultralight Trike, and the

ElectraFlyer-C—later, Fishman is working on a two-place electric airplane he says will be ready to fly this fall. With motor experts, he has developed an electric propulsion kit including 100-hp motor, battery pack and battery management system, and throttle to control the speed at which the batteries discharge.

“We’re using a lot of very inefficient, crappy technologies to waste the gas that we can get so cheap,” says Fishman. “Six-thousand-pound cars to move around people who weigh about 80 pounds. It seems normal to us. This is not the way we should be doing things.”

The irony of electric airplanes is that their economies are tiny. Since electric powerplants are confined, at least for the foreseeable future, to small, light, and slow airplanes that don’t require a lot of energy in the first place, the savings to be realized from using electricity—which is roughly equivalent to $1.50-a-gallon gasoline—is rather small (see “Miles per Kilowatt,” below) . Conventionally powered airplanes with the performance of electric ones use only one or two gallons of fuel an hour, so the difference in direct operating cost is negligible in comparison to the difference in initial outlay: for an airworthy gasoline engine, $100 per horsepower; for an electric powerplant, $400 or more per kilowatt. Greg Cole points out that in 10 years the price of gasoline will probably be “somewhere between bad and horrible.” Besides, the price of fuel isn’t everything; smoothness, quiet, reliability, and freedom from maintenance have value, as would the environmental benevolence of an airplane fueled entirely by locally harvested sunlight or wind.

Outside his hangar, Pete Buck and I survey the rows of tied-down airplanes, sailplanes, and sailplane trailers. Nobody is flying today, because there’s not enough air movement to keep a glider aloft. I reflect upon the dubious economics and ask him point-blank why anybody would buy an electric airplane.

“Stupidity,” he laughs. “It’s just like a hybrid car. You can’t justify a hybrid car economically. You never get the price differential back. Just pump gasoline—there’s nothing better!”

Obviously, he’s kidding. For Buck and Cole and Fishman and others like them, there’s more to it than just a bad bargain. It’s more like a love affair. And if they can fall in love with an idea like this, other people can too. There has to be a reason why, when I’m back in Los Angeles and driving home from the airport, it seems as if every other car I see is a Toyota Prius.

Peter Garrison has flown across the Pacific in a homemade single-engine airplane, but he is afraid of electricity.