Above It All

It took a maze of valves and venturis—and a trio of tycoons—to whisk passengers into the stratosphere.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Arch_B307_Flash_SEP09.jpg)

“I’m becoming unbearably weary,” Chicago Herald reporter Jane Ead scrawled on her notepad as the airplane rocked through yet another storm. “With the altitude, and the rough riding, the pilot was surprised I haven’t become ill.” Ead’s harrowing flight aboard a tiny Boeing mailplane helped launch U.S. passenger air service in 1927, with all its discomforts. Early air travelers flew below the clouds, so they faced every upset the weather could offer. All the turbulence caused airsickness, yet rising higher only shifted the pain.

Trained nurses, the forerunners of today’s flight attendants, were on every flight, and a 1928 international study, cited in Drew Whitelegg’s book Working the Skies: The Fast-Paced, Disorienting World of the Flight Attendant, explains why: “A good deal of their time is spent assisting passengers in various stages of vomiting.” During climbs to clear mountains, cabin air grew reedy, sending the beleaguered nurses “down the aisle carrying oxygen bottles, offering distressed passengers a breath from the mask.”

“My God!” exclaimed famed Navy aviator D.W. “Tommy” Tomlinson to TWA meteorologist Ed Minser on landing his Northrop Gamma from an altitude above 30,000 feet. “I had winds of 100 to 150 miles per hour up there!” Tomlinson’s 1936 flights had touched the jet stream—a kind of pilots’ heaven six miles above Earth, where turbulence falls away, flight grows serenely smooth, and wind (in the right direction) becomes an extra engine.

“Since World War I, everything pointed to the advantages of over-weather flying,” says Boeing historian Michael Lombardi. It simply required finding a way to keep passengers breathing at, say, 20,000 feet—roughly two-thirds up Mount Everest.

In 1936, those were heights where only Auguste Piccard, in a gondola balloon, or Wiley Post, in a Jules Verne-inspired pressure suit, dared venture, and only then by sucking oxygen through a tube. Yet Lockheed’s XC-35 research aircraft could reach that high without the crew needing respirators. The twin-engine XC-35, which first flew in May 1937, was the first American airplane to be pressurized (Germany’s experimental Junkers Ju 49, which had begun flying two years earlier, was the world’s first). “So elements of the technology were out there,” says Lombardi. “It was a question of who could make it a success in everyday passenger service.”

The opportunity came in the late 1930s, when Congress threatened to cancel the government contract for Boeing’s B-17 Flying Fortress (“Four engines! Too big!” went the logic). Knowing that TWA chief Jack Frye, who’d underwritten Tomlinson’s flights, wanted the speed, comfort, and safety of over-weather flying for his coast-to-coast service, Boeing president Claire Egtvedt convinced both TWA and Pan American to underwrite the gamble of trying to convert an unpressurized bomber into a pressurized airliner. Wellwood Beall, who had designed Boeing’s 314 Clipper flying boat airliner, would head the engineering team. Dubbed Model 307, the new airplane would co-opt the B-17’s wings and tail, and its four engines would offer unprecedented power and safety.

“These were Curtiss Wright R-1820 series,” says Boeing flight operations manager Mark Kempton, one of very few modern-day experts to have worked on an R-1820 exactly as found in a 307. “These use crankshaft-driven superchargers to compress intake air.” Engineers call this “boost,” a standard trick to help the cylinders breathe at altitude. Yet the real innovation was that in the 307, a similar system would “breathe” for the passengers. “Twin superchargers were mounted on the inboard engine firewall, driven by a shaft from the inboard engines,” says Kempton. The superchargers would draw hostile air (with just half the density of sea-level air and a temperature at 16,000 feet of 1.6 degrees Fahrenheit) from outside and turn it into breathable air in the cabin.

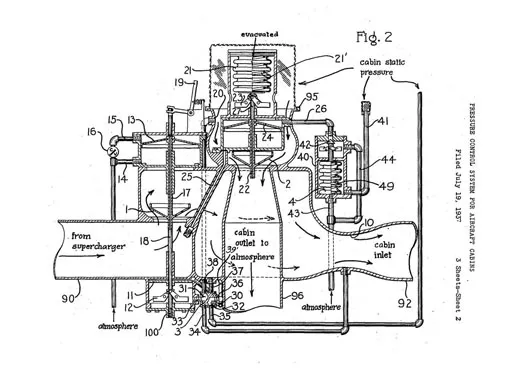

“We consulted Dr. W. Randy Lovelace at Minnesota’s Mayo Clinic, who instructed [the team] on issues related to oxygen want,” Beall recalled in Carl Solberg’s book Conquest of the Skies: A History of Commercial Aviation in America. In his patent for an airline cabin pressure control system, Boeing ventilation expert Nate Price wrote of “the need to supercharge the cabin to promote the comfort of passengers,” but noted, “if an attempt is made to maintain...an absolute pressure [such as sea level], there are produced bursting pressures, which necessitate very great strengthening of the cabin, [making] the airplane economically impractical.”

“The solution was a highly dynamic pressure system,” says Mike Lavelle, a director at Seattle’s Museum of Flight and an expert on the Boeing 307. As Price proposed it, the airplane would rise unpressurized to 8,000 feet, where medical experts believed there was enough oxygen to keep people breathing and functioning normally. Then the superchargers would introduce air to hold cabin pressure to 8,000-foot conditions as the airplane climbed. Higher than 16,000 feet and cabin pressure would fall, since the superchargers couldn’t pull in such thin air (at 16,000 feet, it would feel like 8,000 feet inside the cabin; at 20,000, like 12,000). Yet flying at 20,000 feet, the 307 would still top 90 percent of the weather and passengers would not get airsick.

“It was very well thought out,” Lavelle says. “We still pressurize most commercial airliners to that 8,000-foot standard today.” Yet Price’s invention also demanded exquisite balance. In the rarified air of high flight, the 307 would need to sacrifice some pressure in its cabin to ease the “bulging” effect high-altitude flight induced in the fuselage. But in descent, the airplane would need to repressurize to bear the inward forces its cabin experienced as the aircraft reentered thicker air. You’ve seen this effect in miniature if you’ve noticed a plastic water bottle bulge or dent as cabin pressure changes.

Key to the entire system was Price’s cabin pressure regulator. “It consisted of an inlet valve, which regulated the flow of ventilating air to the cabin, and an outflow value to control the discharge of air,” says Lavelle. In between, a maze of valves, venturis (short tubes with constricted throats), and sylphons (pleated metal bellows) interacted with one another, maintaining conditions inside the airplane as outside pressure varied. Incoming air was drawn via rows of slits on the wings’ leading edges, heated, and then pumped into the cabin; the 307 “exhaled” near its tail. It all happened largely automatically; reporters were so impressed they called the regulator a kind of “brain.” Boeing patent attorney Charles Reynolds saw a bright future for the device. “In a few years,” he told Price, “this ought to be in every plane in the country.”

But getting it to work was another matter. “Once engineers completed the working prototype, they felt the best approach would be to use an altitude chamber to replicate high-altitude pressures, Lavelle says. “But their request was denied, so they used an empty 50-gallon oil drum to fabricate a test rig.” By “supercharging” it with compressed air from a blower, Price and chief engineer Jim Cooper could make the pressure in the drum correspond to different “altitudes,” imitating what the 307 would experience in flight. To their delight, the new cabin regulator held these pressures perfectly—strong proof their concept was sound.

Still, nothing could replace the next step: actual flight tests. “Engineers would have to climb on board the aircraft with their parachutes, climb into the lower fuselage accessory compartment, and make adjustments on the regulators at altitudes of up to 20,000 feet,” Lavelle says. “Fleece-lined jackets—it was cold!” recalls Cooper. With so many parts, the regulator was somewhat delicate. “One failure was traced to human fingerprints left inside the bellows,” says Lavelle. “The oily residue was skewing altitude measurements by 2,000 feet.” Once perfected, production of the regulator was licensed to Garrett AiResearch of Los Angeles.

Aircraft of that day sometimes leaked when it rained, so making the 307 reasonably airtight (even after double rows of rivets) required some unorthodox quality control. All the skin joints were covered by “paw tape,” a Dupont neoprene product developed for the XC-35, recalls Bob Dickson, then newly hired on Boeing’s assembly line. “Then you drove the rivets through. To test for leaks, you covered the joints with Ivory soap and [after pumping in air] watched for bubbles,” he says. It worked. For a final test, a dozen workers soaped down each pressurized cabin, carwash-style, then watched for bubbles and listened for whistling air. (Engineers still leak-test airliners today, but they use much neater ultrasound instruments.) A test rig stressed each of the 307’s curved, plexiglass window panes to nearly triple their expected flight pressure. Cockpit windows also were coated with an alloy to block ultraviolet rays, as flying above the clouds risks sunburn. “After all,” pronounced legendary test pilot Eddie Allen in Boeing’s official account of the 307, “the great thing about pressurizing, is that you [shouldn’t] know you’re up there.” By late 1938, he’d taken the 307 to 22,000 feet.

Despite those successes, TWA major stockholder John Hertz, the rent-a-car king, canceled TWA’s order for five 307s, saying that at $315,000 each, the new airplanes were too expensive. Desperate, Jack Frye contacted Howard Hughes. The young billionaire, who was planning to fly around the world, liked the idea of an over-weather craft. In classic fashion, Hughes bought controlling interest in TWA.

“Hughes spent a lot of time poking around the plant,” Dickson recalls, “frankly, often looking like he’d slept in his car.” Perhaps seeking more comfortable digs, Hughes purchased one extra airliner, for himself.

Tragedy struck in March 1939, when the 307 prototype crashed, killing all 10 aboard (seven Boeing employees, two executives from Royal Dutch Airlines, which was considering buying a 307, and a representative from TWA). Wing and tail modifications solved the airplane’s technical shortcomings, and Claire Egtvedt dubbed his new airplane the Stratoliner, to highlight what he called “travel in a new region of the atmosphere.” “Outside scientific circles,” he told reporters with suitable flourish, “[this] substratosphere has been regarded as something mystical. But before many years, I believe we will all become familiar with this superhighway of the air.”

Travelers agreed. “See you at breakfast,” New York Times aviation writer August Loeb imagined telling friends in Los Angeles as a Stratoliner took off at night from New York’s LaGuardia Field. Loeb praised industrial designer Raymond Loewy’s lavish interiors (“with dressing room for men, and ‘charm room’ for ladies”) and listened in as stewardesses explained the virtues of supercharged cabin air to passengers. What was “Stratolining” like? By night, cloudless skies resembled a planetarium; by day, vistas from Meteor Crater to the Grand Canyon were “visible in a single glance,” wrote Loeb’s colleague at the Times, Malcolm Kerr. Although it wasn’t truly stratospheric (which begins 37,000 feet up), to the pre-World War II crowd, it must have seemed like space tourism. And with a flight from New York to California (with two scheduled stops) taking just 14 hours and nine minutes, Loeb wrote, “the dream of overnight air travel across the United States, has come true.”

Because pressurization enabled it to attain an altitude of 20,000 feet, the Stratoliner offered a vastly smoother ride than long-haul competitors like the Douglas DC-3. Publicity stills of Stratoliner passengers relaxing while their children read the comics offered a new image of flight. Travelers now were living, eating, even shaving in the air. “There is no sensation of altitude, no gasping for air, no shivering in cold drafts,” went one review in Popular Science in 1940. As wide as the later 707, the Stratoliner had room for a crew of five and 33 passengers.

Though pricey, with a cross-country ticket costing $1,000 in 1940 (the equivalent of about $15,000 today), “Stratoliners were always booked,” says Mike Lavelle. For a while, everything went “Strato”—fans could don a Stratoliner hat (guaranteed weatherproof), dress in Stratoliner blue (like the seat color), or join Stratoliner clubs (for tall people).

It didn’t last. By 1942, TWA’s fleet was drafted into the service as C-75 military transports, while Pan Am’s Latin American routes were taken over by the U.S. military’s Air Transport Command. The airplane’s sky-scraping altitude helped ferry Allied brass across the Atlantic. One passenger was British Prime Minister Winston Churchill. “A pretty fair flyer,” recalled TWA Flight Chief W.L. Trimble, despite a penchant (assisted by cabin pressure) for “lighting up those damn cigars!” Another Stratoliner leaped the Himalayas during World War II, carrying China’s Madame Chiang Kai-shek to America.

“It was a great airplane,” says Robert van der Linden, a National Air and Space Museum curator of aeronautics. “It’s just that World War II got in the way.” After the war, larger, faster, and more reliable aircraft took the Stratoliner’s place.

Of 10 Stratoliners built, just one survives, in the Museum’s Steven F. Udvar-Hazy Center in northern Virginia. But the airplane’s legacy lives. Beginning with Lockheed’s Constellation and the Douglas DC-6, both available in 1946-47, later commercial (as well as military and personal) aircraft continue to use systems largely inspired by the 307’s. When aviation topped the stratosphere, the same industry players who “supercharged” this pre-war airplane also provided life support systems for Gemini and Apollo spacecraft—all to breathe easier.

As an aerospace engineer, Nick D’Alto has evaluated modern aviation systems against the rigors of high-altitude flight. Writing about Boeing’s pioneering Stratoliner gave him a new appreciation for how engineers solved the problems of flying above the clouds.