Genchi’s Obsession

A grad student in Italy salvages Germany’s rarest World War I airplane engines.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Genchis_Obsession_4_FLASH.jpg)

You might say that Giuseppe Genchi learned more from his experience outside of school than from the work he did inside. As a 25-year-old student of mechanical engineering at the University of Palermo in Sicily, Italy, Genchi was gazing out the window of a classroom one day in 2007 when he noticed a pile of engine parts in an adjacent hangar. One day, I’ll restore those engines, he thought idly.

Four years later, Genchi is the proud founder of a museum that houses an uncommon collection of German World War I aircraft engines. The Historical Museum of Engines and Mechanisms (www.museomotori.unipa.it) opened on February 25 in the same hangar where Genchi first spotted the old parts.

When I visited the museum just before its opening, the energetic Genchi showed me around the transformed hangar, its neat stands displaying gleaming metal engines and shiny wood propellers, its walls covered in images of biplanes and explanatory signs. “They thought I was crazy,” he says of university administrators. “Everything then looked like a piece of rust, and most professors wanted to throw the lot away.”

Engine experts are impressed by the collection. “He’s found really good stuff,” says Jeremy Kinney, curator of aircraft propulsion at the National Air and Space Museum in Washington, D.C., which has one of the world’s largest and most comprehensive collections of aircraft engines. “Palermo has a collection complementary to ours.” And Koloman Mayrhofer, an Austrian who rebuilds World War I-era airplanes, lauds Genchi’s indefatigable enthusiasm and focus in unearthing and preparing the engines for exhibit. “It is a very long time since such a high-grade collection surfaced, nearly out of the blue,” he says.

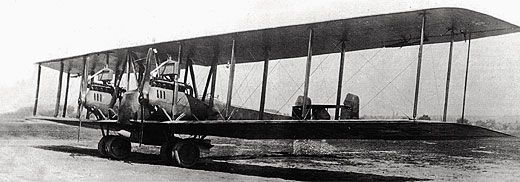

The museum’s gems include a Mercedes D.IV, a water-cooled, eight-cylinder inline engine. D.IVs have powered such aircraft as the Albatros C.V, a beautifully streamlined reconnaissance biplane, and a series of bombers called Riesenflugzeug, or giant aircraft. Some of them were 70 feet long and had wingspans of more than 150 feet, surpassing even the size of some World War II German bombers. Genchi also discovered a BuS.IV made by Basse und Selve, a manufacturer of automobile and aircraft engines. The enormous Siemens-Schuckert R.VIII bomber, with a 157-foot wingspan, had six BuS.IV engines.

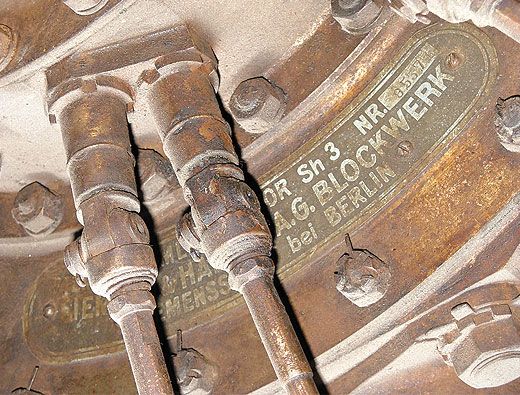

Also in the heap was the Sh.IIIa: The Siemens-Halske engineering firm manufactured the engine between 1917 and 1918 for Albatros, Pfalz, Roland, and Siemens-Schuckert fighters. The Sh.IIIa was “one of the highest developments of a rotary engine in an aircraft, and one of the most promising German designs of the war,” says Kinney. Genchi believes that only about a dozen examples of the Sh.IIIa exist.

The small museum is divided into two areas: the display section and a mechanical engineering lab where Genchi works on his Ph.D. and conducts restorations in his free time. Alongside the aircraft powerplants are Fiat and Alfa Romeo automobile engines dating from the 1920s to the 1990s; Genchi, who has been fascinated by machinery since he was a child, restored them too. “The engine is the union of mechanics and physics,” he rhapsodizes.

To make his dream come true, Genchi invested years in hard work and politicking. His initial curiosity about the old scrap material grew even stronger when he was told in 2007 that no students could enter the hangar, which housed research laboratories and was also used to store engineering equipment. A year later, he found an opportunity to investigate the cluttered space. “I saw the door of the hangar open, and without hesitation went in to take a look,” he says in a lilting Italian accent. “You have to know I’m a very curious person.”

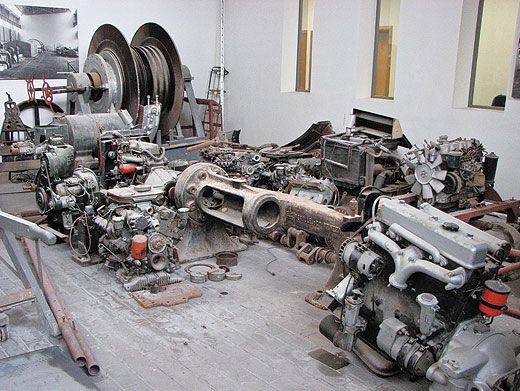

After a month of pestering his professors, he finally got approval to sort through the corroded parts. On his own time, at nights and on weekends, he began to make sense of the heap. And after consulting with historians, Genchi realized he had stumbled upon some valuable antiques (the refurbished collection, he estimates, is worth some $850,000), including pieces of 19th century steam engines used in factories and crankshafts from classic 1950s sports cars. What dominated the mound, though, were the remains of German World War I airplane engines.

That seemed odd to Genchi. How did aircraft engines from Germany, a Central Power in World War I, end up at a university in Sicily, far from the war’s action and in a country that fought on the Allied side? Genchi started surfing the Web, rummaging through old bookshops, and probing Italian public and university libraries. What he discovered was that the Allies feared Germany, the industrial powerhouse of Europe, and cooperated in the first massive disarmament of a modern nation. With the signing of the Versailles Treaty in 1919 ending the war, Germany agreed to scrap hundreds of fighters, bombers, and reconnaissance aircraft.

In a triumphant 1920 British newsreel, the camera pans over an enormous plain of partially destroyed German biplanes. Entitled The Graveyard of Germany’s Air Ambitions, the film shows a Berlin man with a sledgehammer laboring over a neatly stacked row of engines. “Immense numbers of machines and engines are being destroyed under terms of Peace Treaty,” reads the subtitle.

Yet the Allies were eager to learn what they could from German engineering, so a handful of engines were sent to the United States, Great Britain, France, and Italy for study. The Italian Royal Air Force received its share, and several engines were eventually shipped to the University of Palermo’s Antonio Capetti, one of Italy’s leading aeronautical engineers. In the university archives, Genchi discovered a 1926 document listing the inventory of engines and their provenance. He also found evidence that Capetti or his colleagues took advantage of their access to the German machines in Palermo. He found a blueprint one of them had drawn, for example, documenting the internal structure of an engine. “One of our engines is partially sectioned, and others were taken apart for study,” says Genchi. In 1927, Capetti moved to the University of Padua and then on to a university in Turin, which has a broad collection of aircraft engines.

The analysis of German engines in Italy played a critical role in the country’s aeronautical progress. Studying German World War I technology, says Genchi, benefited the design of World War II aircraft used by Benito Mussolini against the Allies.

Genchi’s restoration work began with the propellers rescued from the scrap pile. He then moved on to the engines, managing to wheedle supplies from the university. Assisted only occasionally by technician Beniamino Drago and a supportive professor, Riccardo Monastero, Genchi laboriously sorted, cleaned, and reassembled. “This is industrial archaeology,” he explains. “And only slowly did I imagine a museum.”

Restoring the Siemens-Halske Sh.IIIa engine—one of the most valuable in the collection—proved one of the greatest challenges. Since the steel parts were never painted, says Genchi, “the engine seemed completely enveloped in rust.” First he tried to remove dirt and debris with a weak solvent that would preserve the natural aging of the metal. “I am inclined to conservation rather than reconstruction,” he says. “I think it’s right to respect even the ravages of time that testify to the antiquity and the history of objects.” But because the dust had turned the metal a dull color, the results of the solvent were disappointing. So Genchi decided to restore the engine to its former luster.

He set about disassembling the entire engine, laying the pieces out on a large table after recording their precise locations. “I discovered with astonishment that the [interior] engine was practically new,” thanks to an internal coating of oil, says Genchi. “Even the piston crowns looked clean and free of burns.” He also spotted serial numbers written by hand during manufacturing.

Genchi meticulously washed each part with water and solvents, scrubbed it with wire brushes to remove the rust, then washed it again with solvent. He followed up by painting all the external parts with a protective varnish to prevent rust. That took almost half the entire time of the restoration. Cleaning and varnishing everything from the tiny plate screws to the massive cylinders (each one could require five hours to sandblast) absorbed months of effort. The crankshaft proved so heavy that lifting it required a crane.

After getting his mechanical engineering degree in April 2009, Genchi won a small grant to complete the museum. He has taken no pay during the two-year project. In the future, he plans to contact Mercedes, Siemens, Fiat, and other companies to supplement his knowledge of the hardware. “For example, it would be interesting to know the correspondence between an engine serial number and the exact aircraft in which it was fitted,” he says. “Often different engines were placed in many different types of aircraft.” In the meantime, Genchi hopes the museum will inspire students and engineering professionals who make the pilgrimage to the unassuming hangar.

He’d like to fire up some of the engines, though that will require more time, money, and space. But comparing the contents of the museum hangar today to what was there in 2007, I have little doubt his World War I engines will someday roar again.

A contributing writer to science and archaeology magazines, Andrew Lawler also writes for Smithsonian, Discover, and other publications.