The Road to the Future… Is Paved With Good Inventions

We bring you 10 great ideas that made flying safer, easier, or just a whole lot more fun.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Today_Future_Flash_SEP09.jpg)

The Tomcat’s Brain

As a 1968 graduate in electronic engineering, Raymond Holt was in a sandwich generation, caught between vacuum tubes and transistors. When he showed up for his first job, at Garrett AiResearch, the personnel manager told him he was the only one in his department who’d had a class in computer design. AiResearch had just been hired by the Grumman Corporation to design the F-14 Tomcat’s central air data computer, a microprocessor that would, with data from pressure sensors, calculate and report (on cockpit displays) Mach number, altitude, and airspeed, and, accordingly, move the aircraft’s control surfaces and adjust the sweep of its variable geometry wing. AiResearch had designed the McDonnell F-4 Phantom’s central air data computer, but that had been electromechanical. “It had gears and cams,” says Holt. “It’s like a transmission on a car, except that it’s chrome and gold. It was about two feet long and three feet high. When they showed it to me and said I had to make it electronic [to fit on a circuit board 40 inches square] I about freaked out.”

Northrop Grumman engineer Dave Wolfe worked at Garrett AiResearch at the time, where his job was teaching Grumman technicians how the F-14’s central air data computer worked. (“I saw the airplane and I was so impressed that I left [AiResearch] and joined Grumman,” he says.)

“Electromechanical systems were a maintenance nightmare,” says Wolfe. “You needed a very special type of artisan to repair those things — almost a watchmaker. People were looking for something to replace that system.” Garrett AiResearch was the only company to submit a bid for a digital, instead of electromechanical, design, but the small, powerful processors required didn’t exist.

In 1968, the integrated circuit was 10 years old. Jack Kilby of Texas Instruments and Robert Noyce of Intel Corporation had independently developed methods for assembling transistors — switches that in the binary language of computers say “on” or “off” —on a single slice, or chip, of a semi-conducting metalloid, like silicon. (Kilby’s work won him the 2000 Nobel Prize in Physics.)

As a 10-year-old, the integrated circuit had come a long way. It could integrate hundreds of transistors on a single chip, as opposed to the first integrated circuits, used on the Apollo guidance computer, which made do with tens. But it hadn’t come far enough for the F-14’s computer, which demanded as many as 3,500 transistors on a single chip.

In 1968, the circuits were mapped on huge, multi-color Mylar sheets “the size of an entire wall of a commercial building,” recalls Holt. The degree to which that layout could be shrunk — and its detail preserved — to form the pattern for etching on a chip was one limit to a chip’s capacity.

Holt’s team and chip maker American Microsystems created a six-chip processor containing 65,000 bits of data, an achievement Holt believes has been unrecognized because of semantics. Intel Corporation gets credit for producing the first single-chip microprocessor in 1971, but Holt contends that with the F-14A’s first flight in 1970, his team beat Intel to the first microprocessor by a year. Unfortunately, a hydraulic failure on the first flight caused the F-14 to crash (the pilot safely ejected), but the central air data computer performed flawlessly.

—Linda Shiner

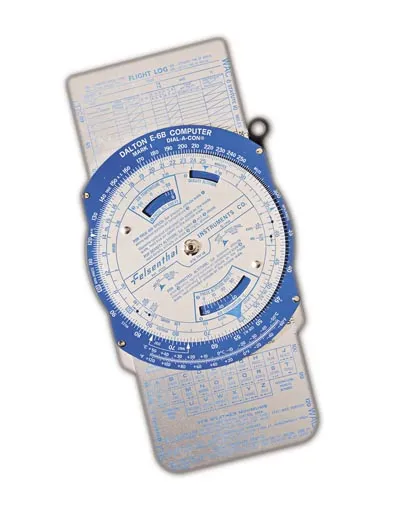

The Whiz Wheel

Since 1940, the E6B, a circular slide rule, has been the student pilot’s computer of choice. Invented by Navy man Philip Dalton and developed with celebrated navigator Philip Van Horn Weems, the device, also called the Dalton Dead Reckoning Computer and the Whiz Wheel, was embraced by the Army Air Forces during World War II, and has changed little since. The logarithmic slide rule uses arithmetic to calculate speed, flight time, distance, fuel burn, and density altitude; the wheel on the reverse side uses trigonometry to calculate how wind will affect cruise flight.

The E6B has made a few appearances on “Star Trek.” In the episode “The Naked Time,” Mr. Spock uses a Whiz Wheel to calculate precisely when the Enterprise will smash into a planet. It’s likely this prop came from the flight bag of series creator Gene Roddenberry or designer Matt Jeffries, both of whom were pilots.

Although many students today use an electronic version, some prefer the plastic or aluminum original. In a debate over the pros and cons of plastic on the Jetcareers Web site, one poster says, “1) It never [exhausts] batteries. 2) It’s smaller and lighter. 3) I am actually quicker with it. 4) (most important) I am an enormous nerd.” However, the Major Nerd award goes to Stefan Vorkoetter, who notes on Stefan’s General Aviation Web site, “The calculator side is also handy for computing tips or comparing unit prices of items in the grocery store.”

—Patricia Trenner

EZ Does It

Burt Rutan hadn’t intended to start a homebuilders’ revolution in 1975; he just wanted to break a record. He’d been experimenting with canards —airfoils mounted forward of the wings — and hoped to demonstrate that an aircraft equipped with them would outperform conventional types. He was thinking about getting into the homebuilt market, and setting a record, he reasoned, would sell a lot of plans.

He wanted to build his record contender quickly, and be able to modify it easily, so he scrapped the aluminum prototype he was working on and borrowed construction techniques from a business that repaired fiberglass sailplanes at Mojave Airport, near his shop. The repair business didn’t have factory tooling. For repairs, Rutan says, “they would put in position the foam core and then they’d fiberglass both sides. And I got the inspiration from that and also from something else: I was a model airplane guy since I was 10 years old. And model airplanes then made their wings with hot-wire-cut foam cores. And I put both of those ideas together — of repairing fiberglass sailplanes and building radio-controlled model wings —and came up with this method whereby you could build an airplane without any molds.”

In August 1975, during the Experimental Aircraft Association’s annual celebration of homebuilding in Oshkosh, Wisconsin, N4EZ, powered by a Volkswagen engine and piloted by Rutan’s brother, Dick, set a closed-course distance record by flying 1,638 miles without landing. The airplane caused such a sensation that the following year, when Rutan issued the plans for the VariEze, a greatly modified design that accommodated a heavier engine, he sold 100 sets the first day. Over the next three years, he sold 4,500.

“Rutan’s great innovation,” says Russ Lee, a curator of aeronautics at the National Air and Space Museum, “was simplifying the basic construction process. He saved homebuilders hundreds of hours of cutting out pieces of wood.”

Before the VariEze, homebuilders needed skills in woodworking and, often, metalworking. Rutan’s customers built the VariEze by using a hot wire to cut foam in the shape of the full-size templates that came with the plans. They then covered the pieces and joined them with high-strength epoxy and sheets of fiberglass.

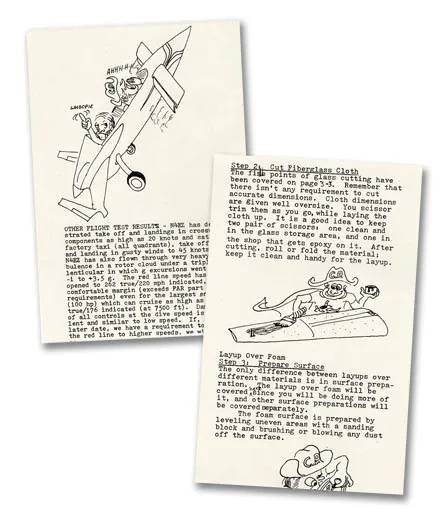

The VariEze builder’s manual opens with Rutan’s manifesto: “It is our intent to drastically reduce the non-completion rate common to homebuilt aircraft.” Sprinkled with cartoons, the directions in the manual have an easygoing, conversational tone. Each step is accompanied by an estimate of the time it should take, which does not include “discussing your workmanship with friends that stopped by to help.” Rutan’s inspiration? Simplicity dress patterns. He says, “If you buy a pattern to make a dress, what you see there is a sketch, and then a sentence or two or three, and then another sketch, and they just walk you through building this dress.”

Of course neither the construction process nor the directions would have mattered had Rutan’s aircraft not looked so singular or performed so well. It is designed so that as soon as the canards stop producing lift, at a certain angle of attack, the airplane automatically noses down sharply. The nose-down attitude keeps the main wings from stalling and makes the aircraft virtually stall-proof. Its winglets — the VariEze was the first aircraft to fly with them — decrease drag, boosting climb rate and cruise speed.

The VariEze carries its engine in the rear, where it drives a pusher propeller. To keep the weight of the engine from tipping the parked aircraft backward and damaging the prop, Rutan created one of the aircraft’s more exotic features: a nose gear that the pilot retracts after parking, enabling the VariEze to bow. Worried about scuffing the nose, Rutan suggested that builders affix some type of bumper under it; he used a hockey puck.

By 1985, Rutan had sold 12,000 sets of plans for the VariEze and its bigger, better performing brother, the LongEZ, which Rutan calls “my best homebuilt.”

Some have suggested that the force was with Rutan in 1975, before the movie Star Wars spread it to the rest of the world. The film was released in 1977, the first full year the VariEze plans were sold, and many see a resemblance between the dashing X-fighter spacecraft that George Lucas created for the screen and the otherworldly VariEzes that were proliferating at small airports across the country. The VariEzes don’t have the “X” configuration and aren’t propelled by whatever exotic method the X-fighters use, but they do have one thing in common with the movie-star airplanes: Thirty-four years later, they still look like the future. (Read our recent interview with Rutan.)

—Linda Shiner

A Little Extra Oomph

When the u.s. air force and the National Advisory Committee for Aeronautics started exploring high-speed flight with the Bell XS-1 in 1947, off came the lid of a Pandora’s Box of aerodynamic woes that had only been hinted at as piston-engine aircraft approached transonic speeds. In October, shortly before achieving Mach 1.06, Chuck Yeager found that as he neared the speed of sound, the XS-1 would no longer respond to control inputs. “I pulled back on the control column,” he told an interviewer for the PBS series “NOVA” in 1997. “Nothing happened. The airplane just went the way it was headed.” Like the gremlin that roamed the wing in “The Twilight Zone” episode “Nightmare at 20,000 Feet,” a shock wave had taken up residence along the horizontal stabilizer, preventing the two small elevators on the stabilizer’s trailing edge from fully responding to pilot input.

Yeager and the rest of the team thought that if the entire horizontal stabilizer rather than just the elevators could be made to move up and down, the “all-moving tail” might be able to win the arm wrestle with the shock wave. Thanks to the NACA design team at Virginia’s Langley Aeronautical Laboratory, the XS-1 had been equipped with just such an adjustable stabilizer — a sort of gigantic trim tab. The XS-1 team set to jury-rigging a fix. “Being a mechanic, all we did was squirt 3-in-1 oil on it and run it up and down, up and down, until it worked,” Yeager said.

On October 14, after the B-29 mothership released the XS-1, the bullet-shaped aircraft reached 94 percent of the speed of sound at 42,000 feet. “I just cranked the leading edge up on the horizontal stabilizer to keep the nose down,” Yeager said. “All the buffeting smoothed out, because the supersonic flow went over the whole airplane.” Then a boom echoed over the high desert: The XS-1 had exceeded the speed of sound.

And that’s what it took to crack Mach 1 without the inconvenience of a catastrophic structural failure. Today, all supersonic aircraft wear all-moving tails.

—Patricia Trenner

Life Saver

Today, most fixed-wing aircraft carry a device that dates back to the insights of one man: Leonard Greene.

Early on, Greene worked as a chemist but pursued a passion for flying. According to family accounts, one clear day in 1937, the 19-year-old was preparing to take a flying lesson at an airport on New York’s Long Island when an aircraft on approach suddenly plummeted to the ground. The pilot was killed. Having witnessed the tragedy, Greene set about learning what caused it.

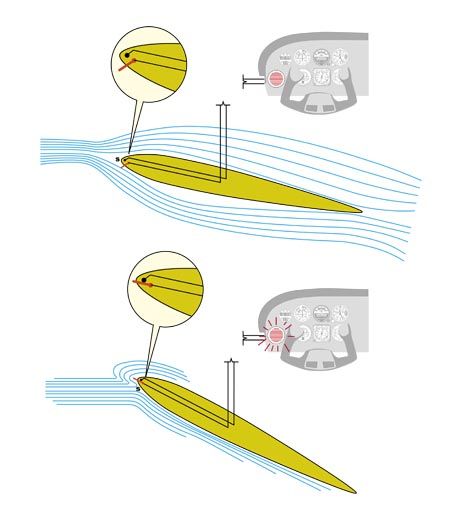

It turned out that the pilot had entered a stall-spin. In the early days of aviation, stalls were a major cause of accidents. An aircraft wing is said to “stall” when it stops producing lift. When air meets the leading edge of an airfoil, part of the flow goes over the top and part goes underneath. (The place where the airflow divides is called the stagnation point.) As the aircraft’s nose pitches up, the angle between the airfoil and the wind increases, and eventually the orderly airflow above and below the wing breaks down. A turbulent storm of air forms over the top surface, and the wing can no longer produce lift.

Greene contrived a simple, wing-installed device that would warn the pilot that his wing was about to stall. He used rudimentary elements: a moveable vane that juts into the air, a small switch connected to the vane, and a battery-powered horn or light (or both). The theory is as simple as the technology: As the wing approaches stall, the stagnation point moves farther and farther aft of the leading edge, until air that would normally flow aft reverses its flow and goes forward; as it flows up and over the leading edge of the airfoil, it pushes the vane forward, closing the switch and in turn sounding the warning horn.

In 1946, Greene started a business, Safe Flight Instrument Corporation, to manufacture the device. The vane had to be placed so that it gave pilots enough warning to let them push the stick forward and recover before the wing actually stalled, so Greene did extensive testing to establish the best placement of the vane on each airplane type’s wing. During his career, Greene test flew and stalled so many aircraft that he lost count of the number. His son Randall, who today runs Safe Flight Instrument, says of his father: “He could see the air. I don’t mean that as a metaphor. I mean it literally. He could visualize the flow and pressure of air in his mind.” Leonard Greene died in 2006 at the age of 88.

Today, all U.S. aircraft must have some form of stall warning. In addition to Greene’s patented wing device, Safe Flight Instrument and other manufacturers — such as Rosemount and Teledyne — make airflow sensors for use on the fuselage.

Greene continued with his inventions, accumulating more than 200 patents and producing increasingly capable safety systems, such as automatic throttles. But the family business’ most ubiquitous product is its simplest.

—George C. Larson

MeTube

Two decades ago, Richard Branson, founder of Virgin Atlantic Airways, wanted to know what it would cost to retrofit his fleet of airliners with a flat panel display on the back of every seat. The answer: $8 million. The young Virgin Atlantic didn’t have that kind of money, and the bankers Branson went to for a loan didn’t see much promise in the idea. So Branson called Boeing and said he wanted to order some new 747s, all with seatback video screens. Boeing said they’d make it happen. In the end, Branson borrowed $2 billion to buy the jets, and let Boeing sweat the details. In 1991, Virgin became the first airline to offer seatback video in all classes of service.

Today, any airline that flies long-haul routes is expected to have seatback video. The technology, provided mainly by Panasonic, Thales, and Rockwell Collins, was created in 1982 —before Branson’s brainstorm —by a company called AirVision, founded by Los Angeles businessman and engineer Arn Steventon. AirVision later became part of Warner and Philips.

Branson now offers the everyman screen on all Airbus A319s and A320s flying for Virgin America, his two-year-old U.S.-based airline. Passengers use remotes with standard volume, channel, and forward/back controls. On the remote’s flipside, a mini keyboard lets them text chat with other passengers over a wireless network. They can build a playlist of favorite tunes from a library of 3,000 songs, and the system remembers it on their next flight.

“It’s not necessarily the explosion of the seatback screen,” says John Norman White, historian and co-founder of the World Airline Entertainment Association. “That’s the delivery part of it. The revolution is on the front end — the leap to giant servers. Very soon we’ll have a total of a terabyte of capacity on board that that will enable an airline to present 500 movies and 2,500 compact discs to its passengers.” Already, fliers on Emirates Airlines, a leader in inflight entertainment, can punch in their birth year and the system will play the top tunes from that year. Or they can select from specially made BBC content, such as a lengthy documentary on the history of classical music, with experts discussing composers and arrangements.

The Singapore Airlines A380 is a flying tradeshow of inflight entertainment. Singapore flies the farthest route, 10,371 miles, and the longest duration, 18 and a half hours, and considers inflight entertainment critical to passenger sanity. Business Class passengers enjoy 15.4-inch high-resolution screens, while the Suites Class fliers tune in to a 23-inch liquid crystal display that comes with a pair of Bose noise-canceling headphones. But everyone on the airplane, including those in Coach with 10.6-inch screens, has access to the airplane’s riches of movies, TV shows, music, and computer games.

“What blows my mind is the cost of it,” says White. “If I told you the most expensive thing on an airplane is the airframe itself, that’s no surprise. And the engines come second. That probably wouldn’t surprise you either. But on the modern 777, the A380, the 787, the third highest expense is, you guessed it, the inflight entertainment system. You’re talking $15 to $20 million easily.” And that’s just for the hardware. Content costs millions more to license from domestic and international movie studios and record companies. Over the life of an airplane, say Boeing officials, the cost of inflight entertainment actually exceeds that of the engines. According to analyst Walé Adepoju of the Inflight Management Development Centre in London, between 2007 and 2012, airlines will be adding these systems to 3,000 commercial jets, at a cost of $4.6 billion.

By then, passengers may buckle in and view a screen that greets them by name, shows images of their destination, and informs them that a LinkedIn or Facebook friend is on the flight. It might schedule a dinner reservation in the city where they’re headed. It probably won’t follow them to the restaurant and serve the wine. But stay tuned.

—Mike Klesius

Push-Button Flying

Among William Lear’s 150-plus patents are designs for the first practical car radio, the Learjet, even the eight-track stereo tape player. But Lear’s most successful creation was the autopilot. While the technology had been around since 1914, when father-son team Elmer and Lawrence Sperry held a demonstration in Bezons, France, the autopilot was found only in slow-reacting airplanes such as airliners and bombers. In 1949, Lear transformed aviation when he developed a miniature autopilot (which he holds in the photo) and the first fully automatic landing system for use in supersonic fighters. The achievement earned him the National Aeronautic Association’s prestigious Collier Trophy.

A Swimming Success

Astronaut-wannabes take note: When dangling from the end of an umbilical cord 160 miles above Earth, you want to be anchored. For the unanchored, even flexing a pinkie will send you tumbling “ass-over-teakettle,” as veteran spacewalker Buzz Aldrin explained in his memoir Men From Earth.

While it’s now commonplace for astronauts to prepare for the weightlessness of space by training underwater, in the earliest days of Project Gemini, the norm was aircraft simulations: Trainees would be taken up in a KC-135 Strato-tanker, which would fly a ballistic trajectory, giving the passengers a brief period of freefall.

Of course, no one knew what to expect in real micro-G. When cosmonaut Alexei Leonov —armed with a suicide pill in case things went horribly wrong —first stepped into space from the Voskhod 2 spacecraft on March 18, 1965, he was sweating so profusely that his spacesuit sloshed when he moved.

The first American to perform an extravehicular activity (EVA) was Gemini 4’s Edward White, who on June 3, 1965, made a 36-minute excursion to evaluate the feasibility of spacewalking. Except for wrestling with a jammed spacecraft hatch, things went as planned. No one made another EVA until Gemini 9, when, on June 5, 1966, Gene Cernan exited the spacecraft, using handrails, Velcro pads, and foot restraints to help keep him in place. Even with these devices, Cernan was unable to control his movements, eventually running into an antenna and tearing the outer layers of his spacesuit.

During his second EVA on Gemini 10, Michael Collins let go of the handrail for an instant, causing his body to smack the spaceship’s side so hard that the attitude control system’s thrusters fired in compensation.

It was clear to NASA that EVA training needed to be modified.

The Gemini astronauts had a swimming pool at their disposal — courtesy of the McDonough School of Boys in Baltimore, Maryland — and even though underwater simulations weren’t mandatory, Aldrin made extensive use of the pool.

“I was an experienced scuba diver before beginning astronaut training,” he wrote in 1989, “and it seemed to me that practicing underwater was better preparation for an astronaut’s EVA than with the wire-and-pulley training gadgets that came and went in Houston, but never really worked.”

The underwater training paid off: during Gemini 12 in November 1966, Aldrin made three successful spacewalks. From then on, underwater training was mandatory. And it’s still used today, with astronauts spending hundreds of hours underwater before setting foot in space. “Your first underwater training includes a rite of passage,” says Greg-ory Harbaugh, a former NASA astronaut, veteran spacewalker, and now president and CEO of the Sigma Chi Foundation, which provides scholarships to fraternity members. “It’s called ‘doors and latches training,’ and people don’t do well the first time out. You’re holding a very heavy tool that wants to drop to the bottom of the pool. You’re upside down. It can be very humbling. And I think that’s the goal of EVA training. You can’t be arrogant; you have to know what your capabilities are and what the overall team’s capabilities are.”

Since 1996, astronauts have trained in the Neutral Buoyancy Laboratory at Houston’s Johnson Space Center, which boasts a mammoth tank (202 feet long, 102 feet wide, and 40 feet deep) that took nearly a month to fill. “In the old tank you couldn’t do a whole heck of a lot,” says Harbaugh. “Now you can put an entire spacecraft in there. It’s a quantum leap forward.”

—Rebecca Maksel

Stud, Spring, and Grommet

In the early 1930s, when aircraft manufacturers began to switch from wood to aluminum alloys, a 36-year-old Ukrainian immigrant working at Fairchild’s American Airplane and Engine Company on Long Island, New York, invented a simple fastener that would make Dzus if not a household name at least a hangar name.

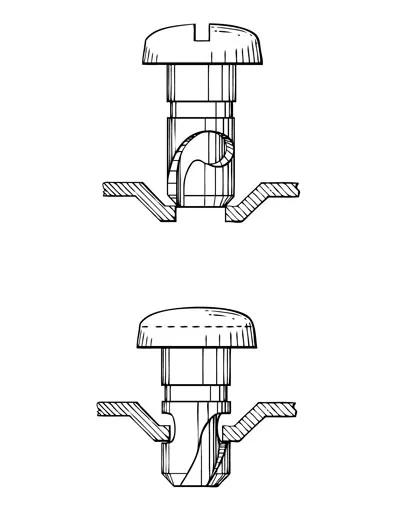

William Dzus (pronounced “Zeus”) observed that when Army Air Corps fighters landed, the cowlings clattered, and he traced the racket to the practice of attaching the cowling panels to the engine rather than to the airframe. The various fasteners of the day were subject to an overload of engine vibration and failed regularly — and when they did, the cowling fell off. Although Common Sense twist-lock fasteners had been in use for 20 years, Dzus designed a quarter-turn fastener that was much more effective in minimizing vibration, and because its spring assembly fit neatly inside the panel it was fastening, it induced much less drag than its predecessors. It could even be counter-sunk to eliminate drag altogether. Dzus fasteners proved invaluable for securing inspection panels and other plates needing a quick release.

Fairchild demanded that Dzus sign over the patent to the fastener or leave. Dzus took off, setting up his own manufacturing facility. In 1932 he received his first order: 16 fasteners, at 25 cents each, from Amphibions Inc. Soon the Army Air Corps named the Dzus fastener the gold standard, and perhaps even used one to secure the 15 pages of “MIL-F-25173A(ASG) Military Specification: Fastener, Control Panel, Aircraft Equipment,” which defined the care and feeding of the Dzus fastener.

After the war, the fastener started showing up on motorcycles, hot rods, and all sorts of equipment that required fast access to its innards. Even the turbojet-powered land speed racers of the 1960s (see “The Bonneville Jet Wars,” Feb./Mar. 2009) relied on Dzus fasteners. Says Tony Moore, an airframe- and-powerplant mechanic in California, “After removing and replacing thousands of screws, I’d say that Dzus fasteners are a blessing to anyone who turns a wrench on an airframe.”

By the time William Dzus died, in 1964, some 6,000 variations on his simple, self-locking fastener had been developed. The company, now called DFCI Solutions, still maintains a plant on Long Island and states proudly on its Web site (www.dfcis.com): “For more than 60 years, [we] have designed a wide range of…devices suited to meet your fastening needs.”

—Patricia Trenner

Take a Seat

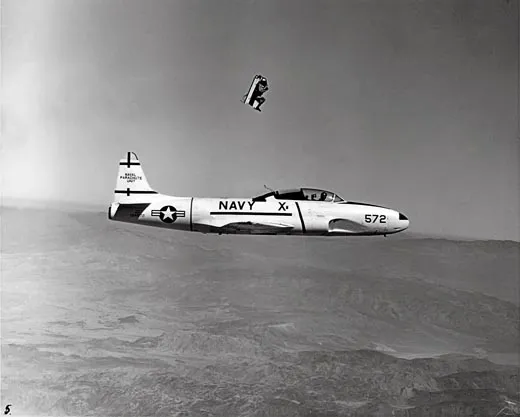

in a 600-mph death spiral at 15,000 feet, what’s the most important thing in the cockpit? Possibly the ejection seat handle. Though World War II aircrews had backpack parachutes, over-the-side bailouts frequently resulted in injury or death. But after the German government developed an ejection system in 1939 (and the Swedish, British, and U.S. governments followed suit), survival rates dramatically improved.