Torture Chamber

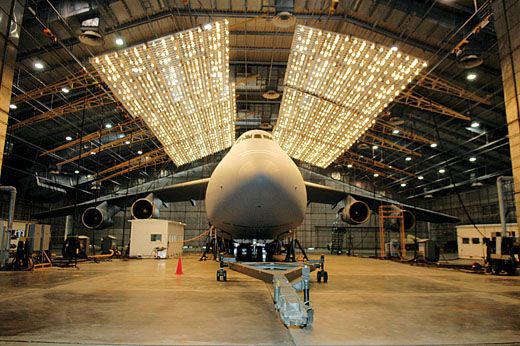

Because airplanes must fly in the real world, the Air Force built a fake one.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/ef/4a/ef4af8f7-c406-44f8-9c1b-f243e0bf8908/06f_fm06.jpg)

ON A 95-DEGREE MID-SEPTEMBER DAY IN THE FLORIDA PANHANDLE, a Raytheon Hawker Horizon business jet taxied up to a hangar at Eglin Air Force Base, a joint-use facility whose civilian side is the Okaloosa Regional Airport. The “Hawk,” as it is called at Raytheon, is a glossy new eight-passenger bizjet to which the Federal Aviation Administration granted a provisional type certificate in December 2004. However, a bit of additional testing was necessary to gain final FAA approval, so the aircraft was towed inside the hangar, where technicians hooked up its two Pratt & Whitney turbofan engines to a pair of exhaust ducts, ran instrumentation cables to a sound-protected, temperature- and humidity-controlled observation booth, and chained the aircraft to a set of anchors embedded in the concrete floor.

The next morning it was –40 degrees inside the hangar, which had been sealed against the outside. The Raytheon test crew entered the aircraft, started the Hawk’s engines, and, after a short countdown, slammed them to full power. The engines boomed for about an hour at various power settings as the hot exhaust streamed through ductwork and out the rear of the hangar; nevertheless, the indoor temperature remained a steady and crisp –40. By rights, two jet engines running at high speed inside a closed space should have created a vacuum that would have collapsed the hangar and drawn the debris through the engine intakes. The reason that didn’t happen is just one of the technological marvels of the McKinley Climatic Laboratory, the world’s largest torture chamber for aircraft in search of FAA or military certification.

The McKinley lab can create just about every weather condition imaginable, and some that are unimaginable. “We can make it rain up to 25 inches per hour,” says lab director Kirk Velasco. Using the type of snow machines found on ski slopes, lab workers can produce whiteout blizzards in the chamber. They can create fog, wind, and icing, generating a layer of “unlimited ice thickness” over your entire aircraft (along with icicles that hang from the ceiling, some weighing 200 pounds), then follow such a display with a scorching burst of simulated solar radiation. They can vary the relative humidity between 10 percent and 100 percent. Moreover, they can do this for aircraft of any size, including a Boeing B-29, a Northrop B-2, a Lockheed C-5A, a Lockheed Martin F-22, a Boeing 747, general aviation airplanes, and helicopters, all of which have been run at full power (and the helicopters at full collective) through McKinley’s weather gantlet. The only airplane too big to pass between the lab’s dual 15-inch-thick, stainless steel, 200-ton hangar doors is the forthcoming Airbus A380 airliner, whose wingspan is about 10 feet too long. “They’ll have to chase the weather,” says Velasco of the Airbus testers. “We’re not the only game in town: Mother Nature also provides. You can chase icing clouds to find icing conditions. It just takes a lot more time, and you do a lot of flying around.”

Over its nearly 60 years, the McKinley lab has tested every military aircraft in the current U.S. inventory, plus many civilian craft, not to mention a gaggle of missiles, bombs, Humvees, tanks, trucks, howitzers, ground-support equipment, hard- and soft-walled shelters, and even cars and snow tires, among other things. For smaller items and more specialized climatic cruelties, the McKinley lab has five test cells in addition to the cavernous Main Chamber. The Salt Fog Chamber can produce an oven-like 149 degrees and a jungle-like 100 percent humidity, together with a corrosive fog solution consisting of five percent sodium chloride in water. The Sun, Wind, Rain, and Dust Chamber can blast various commercially available grades of sand at a test item for hours at a time.

Recently, Velasco and his group subjected a 25-mm Gatling gun from a Lockheed AC-130U “Spooky” gunship to conditions perhaps encountered regularly in the Gobi desert. “We did a major sand test,” he says. “I mean we beat the crap out of it with sand—40-mile-an-hour windblown sand—for six hours.” Afterward, when lab workers aimed the Gatling gun at an in-house bullet catcher and fired, the weapon still worked.

Concern about the effect of cold weather on aircraft led the U.S. Army Air Corps to establish the Cold Weather Detachment at Ladd Field, Alaska, in 1940, and place it under the command of Lieutenant Colonel Ashley C. McKinley, a former dirigible pilot who had photographed American explorer Richard Byrd’s expedition to the Antarctic in 1928 and ’29. After a short stint at Ladd, however, McKinley realized that instead of flying each prototype aircraft to Alaska and back, it would make more sense, and cost the military much less, to create weather on demand, mechanically, at a geographic point that was easy to get to. McKinley also thought it reasonable that all U.S. combat aircraft be required to operate at –65 degrees.

In 1943, the U.S. Army Air Forces directed that an immense climate-controlled hangar be built at Eglin Field in Florida. Four years later, in May 1947, the Eglin Climatic Hangar was in operation, and within 50 years it had run its heavy weather conditions across more than 300 aircraft and 2,000 pieces of equipment. Between 1994 and 1997, the facility underwent a ground-up renovation, which created the lab that is in place today.

Although the principles of refrigeration are comparatively simple and relatively ancient (the first U.S. patent for mechanical refrigeration was granted in 1851), the scale and complexity of the cooling system at McKinley boggle the mind. The Main Chamber has two basic refrigeration modes (plus a heating mode), the first for cold-soaking the aircraft when its engines aren’t running. The setup here is a closed-loop system, the same in principle as that found in a home refrigerator or window air conditioner: Cool a refrigerant, send it through a set of coils, and then blow air over the coils. Doing this on the vast proportions of McKinley’s three-million-plus cubic feet of airspace is a simple matter of scaling up all the components: gigantic, screaming compressor pumps, huge squirrel-cage fans, monster cooling coils, and massive jolts of power. (McKinley has its own electrical substation so that when the system starts running, lights don’t dim in the surrounding community. As it is, the lab’s electric bill averages between $100,000 and $200,000 a month.)

During closed-loop operation, fans withdraw ambient air from inside the chamber, blow it over the cooling coils, and send the cold air up into ceiling ducts that distribute it through large circular diffusers. The same air is recycled through the system again and again, reducing the chamber’s temperature incrementally with each pass. (For high-temp tests, steam is run through the coils.)

The situation changes, however, when an aircraft’s jet engine is running, something that cannot happen in a closed system due to the process of combustion, which sucks in copious amounts of hangar air and forces it out through the engine exhaust system. All that air must be replaced at the precise rate at which it is being consumed. Plus, with the engines and exhaust ductwork radiating heat into the hangar, the incoming air must be cold enough to maintain the target temperature. Keeping up with all that heating and venting requires a whole new dimension in cooling and airflow management, which at McKinley is a masterpiece of engineering called the air makeup system.

“The air makeup system will take that outside air at 95 degrees, cool it down to –40 degrees, and dump it into the chamber at the exact same rate that the engines are using it,” says Velasco. The system has two primary components, the first of which is the air makeup building proper, which is a separate, free-standing, two-story structure housing an air-intake duct, one steam coil and two successive ranks of air conditioning coils, and an exhaust duct that pours a continuous volume of fresh-frozen air into the Main Chamber through a large square hole in the ceiling.

However, there is no way that even McKinley’s powerful compressors can produce the mass of cold air needed to balance a 747’s four engines running at cruise power for a solid hour. The solution: Chill a whole lot of coolant in advance and store it at low temperature until it’s needed. Accordingly, for two days prior to the Raytheon Hawker Horizon test, McKinley’s air makeup team has been cooling down the facility’s most potent refrigerant, R30, a.k.a. methylene chloride, to a temperature of –100 degrees, then shunting it into a 750,000-gallon cylindrical tank adjacent to the air makeup building. Big as a house, that tank of liquid frigidity is really the crux of the entire enterprise.

“This system can take outside air as hot as 105 degrees Fahrenheit and cool it down to minus 80 degrees Fahrenheit, at a rate of 1,000 pounds mass of air per second,” says Velasco. “So as long as your engines aren’t using more than a thousand pounds mass per second of air, we can maintain the conditions in there while those engines are operating.”

Lab personnel are kept informed of equipment functioning by the Facility Monitoring and Control System, a room that runs 24/7 to keep tabs on the facility’s hundreds of valves, miles of piping and electrical circuitry, and compressor pumps, steam boilers, heat exchangers, evaporators, condensers, nozzles, ducts, fans, backflow dampers, plenum doors, cooling towers, surge tanks, storage tanks, coil banks, pressure vessels, and large-scale fluid flows. A day’s use of the Main Chamber can cost between $10,000 to $25,000. If all you’re doing is a simple snow-load test of a tent, figure the lower end. “If you have something really complex,” says Velasco, “like a military Joint Strike Fighter, the F-35, the short-takeoff-and-landing version—it’s got a big lifting fan in the middle, it’s got variable exhaust in the back, a very complicated exhaust setup that we have to specially design and build—that gets up to $25,000 a day.”

Velasco, a thin, balding aeronautical engineer in his late 40s, came to Eglin in 1984 after spending three years doing climatic testing at Edwards Air Force Base in California’s Mojave Desert. One of the tests involved bringing a Lockheed F-16 to McKinley for the full treatment. The place impressed him so much that he transferred to Eglin and never left.

In the years since, Velasco has seen it all, but the tradition at McKinley is to maintain a strict code of omerta about test results. After all, any aircraft, military or civilian, is manufactured by a company whose board members would rather that the outside world not know that during one of the lab’s –40-degree tests, its precious airplane’s landing gear wouldn’t retract or, worse, extend.

“I hate to talk about stuff like that,” Velasco admits. Nevertheless: “I remember vividly—and I won’t mention the name of the aircraft—but we had a large aircraft in here and we did a rain test on it, and we filled it up with water. I mean, water was draining out of that aircraft for two days after we shut down. We could open panels and there were wing cavities filled with it. It was like a swimming pool, you could jump in and swim in it. It was leaking in because of the way they built the access panels—they were not sealed properly.

“Believe it or not, rain is a tough test to pass,” Velasco adds. “We create a windblown rain, we don’t just rain overhead and sprinkle on the thing. We have big wind machines blowing 50-mph winds, and you can blow it up under the wings and from all angles. You blow water everywhere.”

Then, because it’s ancient history, he talks about a B-52 test of a much-touted hydraulic fluid that wasn’t supposed to catch on fire the way conventional fluids did when the bomber’s hydraulic lines got hit by ground fire in Vietnam. “This B-52 had a rotating launcher inside of it that carried cruise missiles,” says Velasco. “The thing’s got to rotate and drop a bomb, rotate and drop a bomb, at minus 65 degrees. We were trying a newfangled type of hydraulic system—that was the whole test. The fluid was less flammable, but at the same time it was much more viscous. It was like molasses at minus 65 versus the old stuff, which would flow relatively freely at minus 65.” So much for the new hydraulic fluid, which the Air Force summarily discarded.

The alternative response to the discovery of a defect is to modify the system at fault. “You’ll have landing gear that won’t come up because they made the hydraulic lines too small, so they have to go back and mod the lines, make a bigger hydraulic line,” says Velasco. “They might have an eighth-inch line down to the gear and it’s just too small, not enough fluid getting there fast enough, so they have to put in a quarter-inch line or a three-eighth-inch line.”

At the other end of the temperature spectrum, heat poses a problem for avionics systems, especially those based on cathode-ray-tube displays, which generate lots of heat, compared to conventional gauges, which don’t. An avionics meltdown, when it happens, prompts the company in question to beef up its “environmental control systems” (air conditioning).

After five days in the deep freeze, the Raytheon Hawker Horizon was covered by a light layer of frost. This was not another sign of lab-induced weather trauma but rather the result of technicians (most of them clad in parkas) repeatedly entering and exiting the hangar, letting in minute amounts of Florida humidity.

During a previous cold test at McKinley, the Hawk had been raised up on jacks so that its gear could be cycled, something that was done without difficulty. On this occasion, with an FAA representative in attendance to verify the results, the flight crew performed a series of low-temperature starts of the auxiliary power unit’s battery, tested oxygen mask operation and the crew alerting system, monitored normal and emergency exit door forces, and so on. All challenges were met successfully. You might say that the whole thing was anticlimactic.

“There’s lots of experience to draw upon,” says Velasco, “and so the newer stuff is a lot better than it used to be in the old, old days.”

When the Hawker Horizon is finally certified and takes to the skies, passengers, crew, and the general public can take comfort in the fact that it passed without a hitch through Kirk Velasco’s little shop of weather horrors.