The Short Life and Death of a Space Tourism Company

They had brains, vision, drive. Where did XCOR go wrong?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/c0/36/c0361cc2-1184-4dc8-84cb-0a1c2b916716/09z_dj2018_earthcurve718254331_live.jpg)

In October 2016, spacecraft and rocket engineering firm XCOR Aerospace tweeted a link to a video. In it, the company’s co-founder, Jeff Greason, outlined his vision for a spaceplane that would be almost as easy and reliable to operate as a commercial jet. “The way to make money in space transportation is the Southwest Airlines model,” he told a documentary film crew. “You keep the wheels in the wheel well. Every minute that [a vehicle] is not in the air gathering revenue is a minute wasted.”

XCOR’s Lynx would be just such a vehicle: a two-seat spaceplane that could take off from conventional runways, use its innovative rocket engines to blast into space, swoop back down to Earth, and do it all over again, up to four times daily. The Lynx promised to revolutionize high-altitude research and unlock suborbital tourism for the masses (see “The Lynx’s Leap,” Oct./Nov. 2013).

“I want us to have a frontier in space,” said Greason in the video. “And if the only way to get that is build it, then I’m going to build it.” So build it he did. Starting in 2008, XCOR tested prototypes, developed new materials, collaborated with scientists, and sold hundreds of $100,000 tickets to fly on the Lynx. Finally, in April 2016, XCOR said that the composite-body, kerosene-powered Lynx might be ready to put its wheels on a runway in early 2017.

Then everything fell apart. A month after making this prediction, XCOR laid off dozens of Lynx employees and announced that it was slowing development of the spaceplane in order to focus on building rocket engines for rival space vehicles. And that was only the beginning of the company’s troubles. A year later, XCOR lost its engine-building contract too, and by the end of June 2017, all remaining employees had been laid off. Greason had long since departed to form a new space startup, and his replacement had been lured away by a senior job at the Pentagon.

**********

The story of the Lynx involves a boardroom battle, underarm deodorant, bank accounts in the Caribbean island of Curaçao, and the desire of thousands around the world to become space tourists. Barring a miracle or a billionaire benefactor, it now seems unlikely that any of the more than 300 ticket-holders will ever ride a Lynx to the edge of space—or see a penny of their money again.

Back in 2008 it all looked quite different to Per Wimmer. The Danish investment banker and adventure junkie had visited more than 70 countries, lived with Amazonian Indians, and skydived over Everest. Now he was looking for a new thrill. Wimmer was already holding tickets for two other private spaceflights when he got a call from XCOR.

“It sounded like a sensible program and sensible people so I bought a ticket on that one as well,” he says. In fact, Wimmer’s $95,000 ticket was for the very first ride on the very first Lynx, which XCOR then planned to have flying by 2011.

The Lynx seemed like a good bet. Virgin Galactic, XCOR’s leading space tourism competitor, was working on a larger but more complex air-launched vehicle, and had yet to announce a firm launch date. XCOR, on the other hand, had been flying rocket-powered craft from its base in Mojave, California, for years.

Founded in 1999 by Jeff Greason and three fellow engineers from the Rotary Rocket Company, a short-lived start-up that attempted to develop a single-stage-to-orbit spacecraft, XCOR was a creature of the experiments-welcome culture of Mojave, where Rotary Rocket was based. XCOR’s dream was always to build an orbital vehicle, but at first the young company kept its business plan secret. “We knew we’d be laughed at,” says Greason today. “At that time, no one had ever paid their own way into space. So we had a cover story that we were building a replica of the Messerschmitt Me 163 Komet [a World War II German rocket-powered fighter].”

In 2001, Dennis Tito became the world’s first space tourist, and XCOR went public with its ambitions. Its first move was to add a rocket engine to a single-seat aircraft designed by prolific Mojave-based aerospace entrepreneur Burt Rutan.

“We wanted to get experience with the platform we had selected for the Lynx: a horizontal-takeoff, horizontal-landing [HTHL] vehicle,” says Michael Valant, formerly XCOR’s director of engineering. Because they were hoping “to treat suborbital flights as if they were commercial airline flights,” according to Valant, the rocket-powered aircraft could prepare them for future spaceplane operations. “You make some routine checks, refill with propellants, run preflight checks, and you’re ready to fly again.”

The logic behind the suborbital vehicle XCOR was hoping to invent was simple: The more moving parts a spacecraft has, the more there is to develop, and the more things can go wrong. Multiple stages, carrier vehicles, and launch pads add up to massive risks and stratospheric expenses that a tiny company like XCOR—then just a handful of people—could never afford. Unlike Richard Branson’s Virgin Galactic, Jeff Bezos’ Blue Origin, and Elon Musk’s SpaceX, XCOR did not have a billionaire’s bottomless pockets to bail it out.

Keeping it simple, however, was not as easy as it sounds.

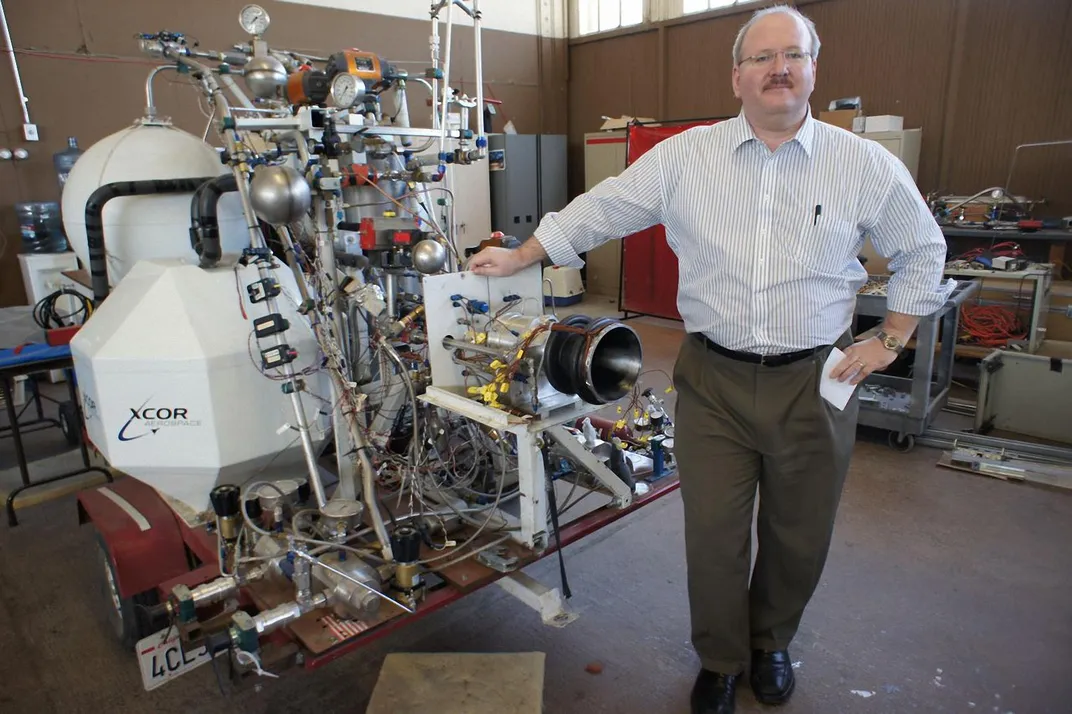

The turbopumps that feed liquid fuel to rocket engines generate enormous pressures, which in turn result in high temperatures. Heat and high internal pressures are extraordinarily hard on machinery. “With turbopumps, you’re always dancing on the edge of having cracks and failures,” says Valant. “Our piston-pump technology is based on automotive engines. While a piston pump will always weigh more than an equivalent turbo, the mechanical stresses are quite a bit lower. Our pumps have a very long service life, and very long intervals between service.” In spring 2013, XCOR successfully fired up the 5K18, the company’s first fully piston-pump-fed rocket engine, on a test stand. To fly, the Lynx would need four such engines, fueled by kerosene and liquid oxygen.

Flying posed aerodynamic requirements that were as daunting as the hurdles in propulsion. The Lynx would have to be controllable from its subsonic launch and ascent, through its acceleration past the sound barrier, and into flight at up to Mach 3 as it hurtled toward its maximum altitude of 62 miles. “[These days] you can make virtually anything fly, as long as you have $200 million to spend on software validation, which we didn’t,” says Greason. “So we had to re-learn the older art of aerodynamic design and go back to wind tunnels. In order to minimize the technical risks, we kept the design very conventional.”

The Lynx’s carbon fiber wings ended up having tips with pronounced upturns. Although these look like the winglets worn by commercial jets to reduce drag, the vertical structures actually provide stability during the extreme conditions of reentry, so the craft doesn’t need a massive tail like that on NASA’s retired space shuttle orbiter.

XCOR had even invented a new composite material, Nonburnite, for building its fuel tanks. While Nonburnite is, as you might expect, nonflammable, it is also stable and nonreactive in the presence of oxygen, unlike traditional graphite and epoxy composites. XCOR planned to deploy the weight-saving material in a Mark II version of the Lynx that would enable it to reach 62 miles.

Progress was slower than Jeff Greason would have liked, but by 2012 things were looking up. XCOR had raised $5 million from investors, including Silicon Valley entrepreneur Esther Dyson and a co-owner of the Chicago Cubs.

Then in July, XCOR announced it would be relocating its headquarters from Mojave, near Los Angeles, to Midland, Texas. The move was not popular among staff, but Midland was offering $10 million in cash to cover XCOR’s relocation costs, property expenses, and some payroll costs. “At the time Midland made their offer, the funding was very much needed,” remembers Valant. The only proviso was that the company would have to create new jobs in Midland—12 million dollars’ worth within six years.

The space industry suddenly started paying attention. Craig DeForest, a solar physicist at the Southwest Research Institute in Colorado, studies the solar wind. DeForest had been using NASA sounding rockets to get his instruments high enough to make observations, but they proved expensive and unreliable. “We thought we could take advantage of high-volume commercial suborbital flights to get instruments into space with a lower barrier to entry,” he says. “In 2012, XCOR was the most responsive of the upstart commercial space companies. They allowed us to get into the nitty-gritty of the engineering really fast.”

XCOR was also making waves in popular culture. Heineken and KLM, the Dutch national airline, both inked sponsorship deals, but XCOR’s breakthrough moment came during the 2013 Super Bowl, when the male grooming brand Axe announced it would use the Lynx to send 23 of its customers into space. American viewers may have found its tagline, “AxeTronauts,” a stretch, but most of the company’s international customers know the deodorant by another name: Lynx. This was XCOR’s biggest ticket sale to date; it gave the tiny company global exposure it could never have afforded.

Not all the attention was positive. SpaceShipOne designer Burt Rutan, whose airplane XCOR had modified to demonstrate its rockets, considers horizontal takeoff and landing a risky business. “Anything designed for HTHL would be more than three times as heavy as [the air-launched] SpaceShipOne for the same payload, and dangerous to fly,” he says. Why? An air-launched spacecraft is carried aloft by its mothership, but the Lynx has to carry the fuel necessary to reach the same altitude. “A rocket failure at takeoff or during low-altitude climb would make a smoking hole,” says Rutan.

Greason was confident of the decision to launch from a runway, but he now regretted the decision to give the Lynx a conventional configuration. “I think that was my biggest mistake,” he says. “We did not go innovative in the vehicle design because we thought nothing like that had ever flown before. It seemed a bridge too far.”

Even with a conventional shape, almost every component had to be custom-designed rather than bought off the shelf. “The deeper we got into the design, the more difficult it appeared to be,” says Greason. “The schedule started stretching out, and we needed more money.”

The ideal solution was close at hand. The company that had been hired to sell tickets for a ride on the Lynx was Curaçao-based Space Expedition Corporation (SXC); its Dutch owners, including businessman Michiel Mol, made Greason an offer he couldn’t refuse. They would help generate $14 million in funding—as long as XCOR bought SXC and gave them seats on the company’s board of directors.

Despite some misgivings, in 2014 Greason approved the deal. At first, development of the Lynx continued as before. But with every step forward, the effort seemed to take another two back. “We kind of opened Pandora’s box on mechanical issues like load transfers,” remembers Valant. “The more we learned, the more we uncovered ‘unk-unks,’ or unknown unknowns. We had a lot more problems that would take serious man-hours to solve than we had budgeted for.”

Southwest Research Institute’s DeForest saw his plans for a solar observatory fading. “As we developed our payload, it became clear that the payload was going to be ready before the rocket was,” he says. “Eventually, our contract with NASA was nearing the end, and the Lynx flight was nowhere in sight.” DeForest modified his miniature observatory to fly in stratospheric balloons made by World View, a rival in the commercial space market. His prototype system made its maiden voyage in September 2016.

In early 2015, matters came to a head. Although Greason had structured the SXC investment to keep himself in the driver’s seat, the Dutch shareholders now aligned with earlier investors to wrest control of the board and oust him as CEO.

The new CEO was Jay Gibson, an aerospace veteran with a background in government and military contracts. His mission would be to raise the funds needed to complete the Lynx, leaving Greason in charge of engineering. But within months, Gibson had relieved Greason of his managerial duties, pushing Greason and two other XCOR co-founders to leave the company.

The move to Midland had also stalled partway, with only some engineers and equipment making it to Texas before money troubles cropped up again. “It was like watching a person step across a stream and then realize they don’t have the leverage to pick up their other foot,” says Valant. “We needed to either complete the move or step back, and [we] could not do either.”

Apart from the Lynx, XCOR had also been working with United Launch Alliance, a joint venture between Lockheed Martin and Boeing, on a liquid oxygen–liquid hydrogen rocket using XCOR’s piston pump technology. In March 2016, XCOR signed a contract through the Air Force to develop an upper-stage rocket engine for Vulcan, ULA’s next-generation launch system. This would be the company’s only revenue until Lynx flights began.

One source, who has since left XCOR and would speak only on condition of anonymity, says that the talent needed to fulfill that contract had left the building. “Without Jeff Greason [and another co-founder],” the source says, “the sophisticated engineering solutions we had relied on quickly dried up. The team was left without any experienced technical leadership.”

Jay Gibson looked at XCOR’s financials and made a tough decision. “Frankly, when you don’t have the resources, you have to focus,” he said in March, adding: “Propulsion is very, very good for us. It’s what keeps our business viable.”

In May 2016, Gibson laid off a couple dozen workers, about a third of the company, including most of the Lynx’s propulsion and controls engineers and composite fabricators, and its program manager. The remaining staff were still split between Mojave and Midland. “At that point, we had a company that was half its [previous] size or less, still with engineering and manufacturing in two places 1,000 miles apart,” says Valant. “I can’t say that that helped.”

The company limped on into 2017 with the Vulcan engine project. Then in April, United Launch Alliance executives cornered Valant at the annual Space Symposium conference in Colorado Springs with bad news. “They said that funding was going to be zeroed out for the program,” he says. Shortly afterward, Donald Trump announced that Jay Gibson had accepted a senior position at the Department of Defense.

Michael Blum, an XCOR board member, was hurriedly elevated by the board to acting CEO in June. “The company was in terrible financial condition when I took it over,” he says. “To preserve any hope of finding a viable path forward, there was really no other option other than let all of our employees go.”

Now Blum is racing to find an investor to acquire the company or fund the completion of the Lynx or XCOR’s half-built rockets, while the company’s shareholders foot the day-to-day expenses of a handful of engineers working on short-term contracts to finish one small rocket system that Blum considers nearly ready for sale. Blum bought his own Lynx ticket years ago and still hopes the spaceplane will fly one day: “I think we have a moral duty to try and satisfy our customers’ trust, and for a lot of people, including myself, it’s a dream.”

So what about Per Wimmer, the AxeTronauts, and the hundreds of others who are still holding tickets for a suborbital Lynx mission? Many tickets stipulated a down payment of half the $95,000 (later, $100,000 and even $150,000) ticket price. The terms of their deposits were clear: “[XCOR] shall have no obligation to hold any payments in escrow and may use such funds in the course of its business or operations,” reads one typical contract.

Gibson confirmed that the vast majority of ticket money was spent on Lynx development costs: “Our astronaut community has been very understanding. But at the end of the day, the liability to the company would be very limited. So if we were not to perform, then we just all walk away.”

That is not an option for the city of Midland, which handed over its $10 million relocation package on the condition that XCOR would bring high-paying jobs to the area. The six-year grace period for creating those jobs will end next year, at which point the city can try to claw back some of the incentives. Blum says, however, that Midland and other creditors are currently being “supportive.”

Of course, XCOR is not the only space tourism company to never actually launch a vehicle to suborbital space. Armadillo Aerospace and Rocketplane did not even get as far as selling tickets, and no other company—not World View, or Virgin Galactic, or Blue Origin—has sent a single passenger aloft. Says XCOR’s ex-CEO Jay Gibson, “Doing engines successfully is hard, doing launch the way we want to is hard, and doing them together is double-hard.”

Jeff Greason now has another start-up, Agile Aero, which hopes to sell rapid prototyping services to other commercial space companies. “I am disappointed that some of XCOR’s plans did not come to fruition, but we did a lot of things that had never been done before,” he says. “We really led the way in getting people to understand that rockets can be built without national defense budgets.”

Per Wimmer, for one, is not throwing away his Lynx ticket just yet. “XCOR has always managed through the storm,” he says. “I wouldn’t count against them because they’ve always had the ability to lay down for a bit and re-emerge stronger than ever.”

It seems that the optimism of space tourists cannot be dashed by delays, accidents, or even the demise of entire companies. The Lynx may never fly, but the dream of holidaying in space is alive and kicking.

Update: On November 8, XCOR Aerospace filed for bankruptcy after failing to find an investor.