A Helicopter Dreams of Mars

Hitching a ride with the next NASA rover, a new explorer gets a chance.

:focal(1822x1286:1823x1287)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/36/7b/367b900f-c1b3-4359-8f9f-6caf2ffd630a/marscopter.jpg)

The video looks like YouTube clickbait—Worst Drone Pilot Ever. A small, spindly rotorcraft darts maniacally around an enclosed chamber like a crazed winged insect until it finally, inevitably, goes splat! “The crash was phenomenal,” says MiMi Aung, laughing infectiously. “It’s a really fun video.”

Entertaining but also enlightening. The video demonstrated that it is theoretically possible for a helicopter to stay aloft on Mars—in an atmosphere 100 times thinner than Earth’s—and helped convince NASA to greenlight development of the first aircraft to be dispatched to another planet. Eighteen months later, in the same 25-foot chamber at the Jet Propulsion Laboratory (JPL) in Pasadena, California, a larger autonomous model hovered, rotated, and moved from side to side without a glitch. The team behind the Mars Helicopter calls it their Wright brothers-at-Kitty Hawk moment.

Earlier this year, another model, the flight model, was tested successfully in the chamber. Though weighing less than four pounds, this full-size vehicle contains everything necessary to fly autonomously on Mars. A few months from now, it will be attached to the belly pan of a six-wheeled rover in preparation for the Mars 2020 mission. If all goes well, the rotorcraft will be deployed on the Martian surface in 2021, where, over the course of 30 days, it will attempt five historic flights. “This is a game-changer,” says Aung, who is the project manager for the Mars Helicopter. “Right now, we explore deep space from orbit or with rovers, but we don’t have any vehicles taking advantage of the aerial dimension. This will allow us to get to places we can’t get to with rovers—or even with astronauts.”

Gravity on the Red Planet is roughly 38 percent of what it is here on Earth, but the thin atmosphere presented what a lot of smart people believed was a show-stopper. Less air, of course, means less lift. For conventional airplanes, this translates into extremely long, high-speed takeoff runs, and landings would be even more daunting. But a helicopter seemed like a potential alternative since, unlike a fixed-wing airplane, its blades create their own airflow to generate lift. As Aung explains, “A helicopter/rotary-wing craft can build up the required airspeed over the blades while standing stationary.”

In theory, at least. But as a practical matter, nobody knew whether the blades could be spun fast enough to support a fuselage housing motors, avionics, and flight controls, not to mention cameras, radios, and antennas—in short, all the components needed to make the craft useful on Mars. To fully appreciate the challenge, consider that the highest altitude ever achieved by a helicopter on Earth was about 40,000 feet. On Mars, the thin atmosphere would be the equivalent of attempting to fly a helicopter at 100,000 feet.

Larry Young, a rotorcraft wonk at NASA’s Ames Research Center in Silicon Valley, began studying the issue in 1997. “Initially, I was a little bit skeptical,” he says. “However, with additional first-order analysis using insights from aerodynamics for micro-rotorcraft and other micro aerial vehicles—which I was also studying at the time—plus weight-trend information derived from HALE [high-altitude and long-endurance] aircraft, I concluded that a Mars helicopter of less than 100 kilograms [220 pounds] might indeed be possible.”

Hover tests of a four-bladed, eight-foot-diameter, ultra-lightweight rotor built by Micro Craft were conducted in the N-242 environmental test chamber at Ames. The success of the program inspired Young to publish a paper trumpeting the viability of the concept.

Meanwhile, independently, JPL engineer Bob Balaram attended a robotics conference in San Francisco. During a presentation about proposed miniature helicopters, Balaram realized that the Reynolds number—which expresses the performance of an airfoil based on the density and viscosity of the air it’s operating in—of these miniature “mesicopters” would be roughly the same as a helicopter with a bigger wing in thinner air. “So it kind of scaled,” he says.

Stanford University provided an eight-inch-diameter rotor that was mounted on a pivot in JPL’s 10-foot vacuum chamber, which was pumped down to simulate the atmosphere on Mars. When the blades rotated at 7,000 rpm, the pivot changed angle, demonstrating that sufficient lift could be generated to fly in the Martian environment—assuming, of course, that the vehicle were light enough. Alas, funds for the program never materialized.

The idea remained on the shelf until 2012, when Aung was leading then JPL director Charles Elachi on a tour of the Autonomous Systems Division. In one of the labs, drones were being used to demonstrate onboard navigation algorithms. Elachi turned to chief financial officer René Fradet and asked, “Hey, why don’t we do that on Mars?” Balaram dusted off his old research and briefed Elachi about his findings. After mulling it over for a week, Elachi told Balaram, “Okay, I’ve got some study money for you.”

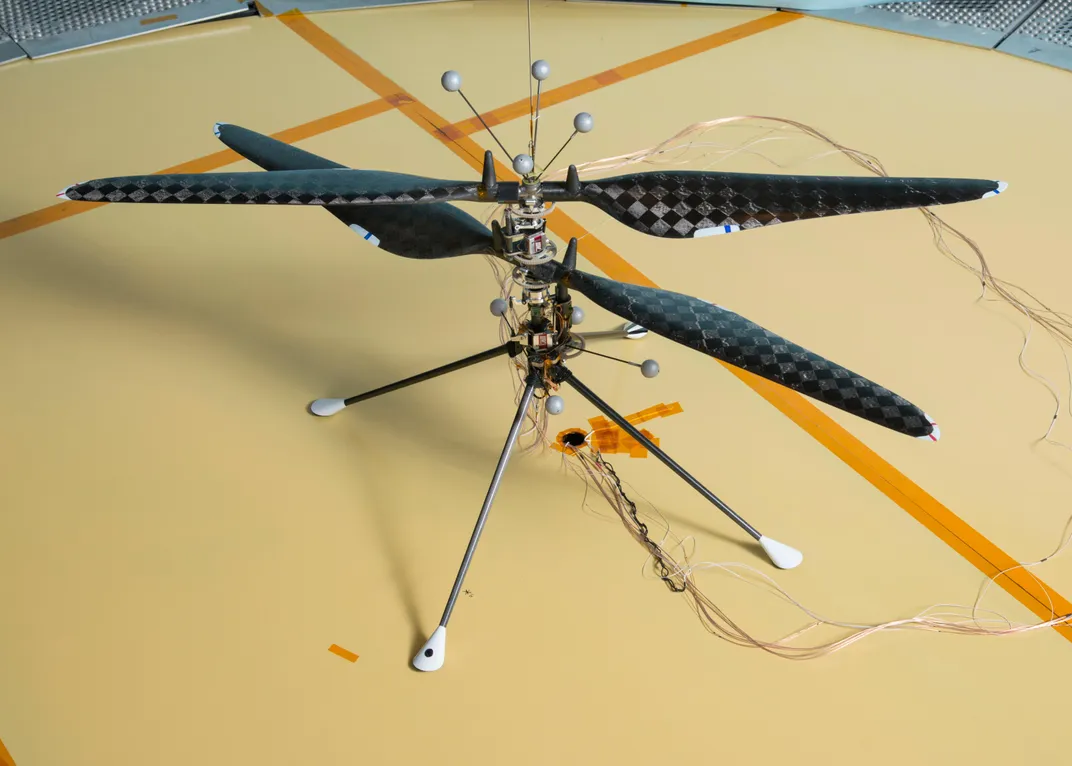

Right from the start, the engineers faced a dual challenge: designing a helicopter that could fly on Mars while also surviving the “seven minutes of terror” of landing on the Red Planet attached to the bottom of a one-ton rover. Packaging considerations limited the length of the blades to no longer than 1.2 meters (four feet).

JPL commissioned AeroVironment, the advanced-engineering firm in Southern California that had created one of the first drones to be deployed in combat—the FQM-151 Pointer—to build a one-third-scale test model. The vehicle was mounted on a vertical rail in JPL’s 25-foot vacuum chamber, a National Historic Landmark officially known as the Space Simulator, where every spacecraft built at the facility since 1962 has been tested. With the blades rotating at 8,000 rpm (to compensate for the small scale), the drone produced enough lift to climb off the ground. This prompted JPL to invest a bit more money to see how well the model could fly without a rail to keep it on the straight and narrow. With Matt Keennon, AeroVironment’s top drone jock, operating a joystick, the model flew freely around the chamber. Too freely, actually, hence the spectacular crash in the Worst Drone Pilot Ever video.

“Rotorcraft are very hard to model,” says Håvard Fjær Grip, a fixed-wing pilot who leads the guidance, navigation, and control team for the Mars Helicopter. “When we flew the vehicle, we anticipated that it wasn’t going to behave exactly as the [computer] model, and it didn’t. But it did what it was supposed to do, showing that it could produce enough thrust to get off the ground.”

On the strength of the one-third-scale vehicle tests, NASA agreed in January 2015 to fund the development of a full-size iteration, which came to be known as the “risk reduction” vehicle. As project manager, Aung realized the program demanded a multidisciplinary structure. She assembled a team of scientists, engineers, and technicians leveraging all of NASA’s expertise. In terms of full-time-equivalent employees, the head count never exceeded 65, but Aung says more than 150 people worked on the program at JPL, AeroVironment, and the NASA research centers at Ames and Langley.

Every decision about the design of the helicopter was filtered through the prism of mass. Balaram, an inveterate backpacker whose office wall is dominated by a dramatic landscape photo shot at one of his campsites, put the vehicle on a diet. “I used the same philosophy that I use with my backpack,” he says. Each additional gram meant more energy to support it, which added even more weight, which required even more energy—a vicious cycle that threatened the entire project. “There was a time when we had a bit of a runaway mass problem, and it was a challenge to stay within the bounds dictated by the physics,” Balaram acknowledges.

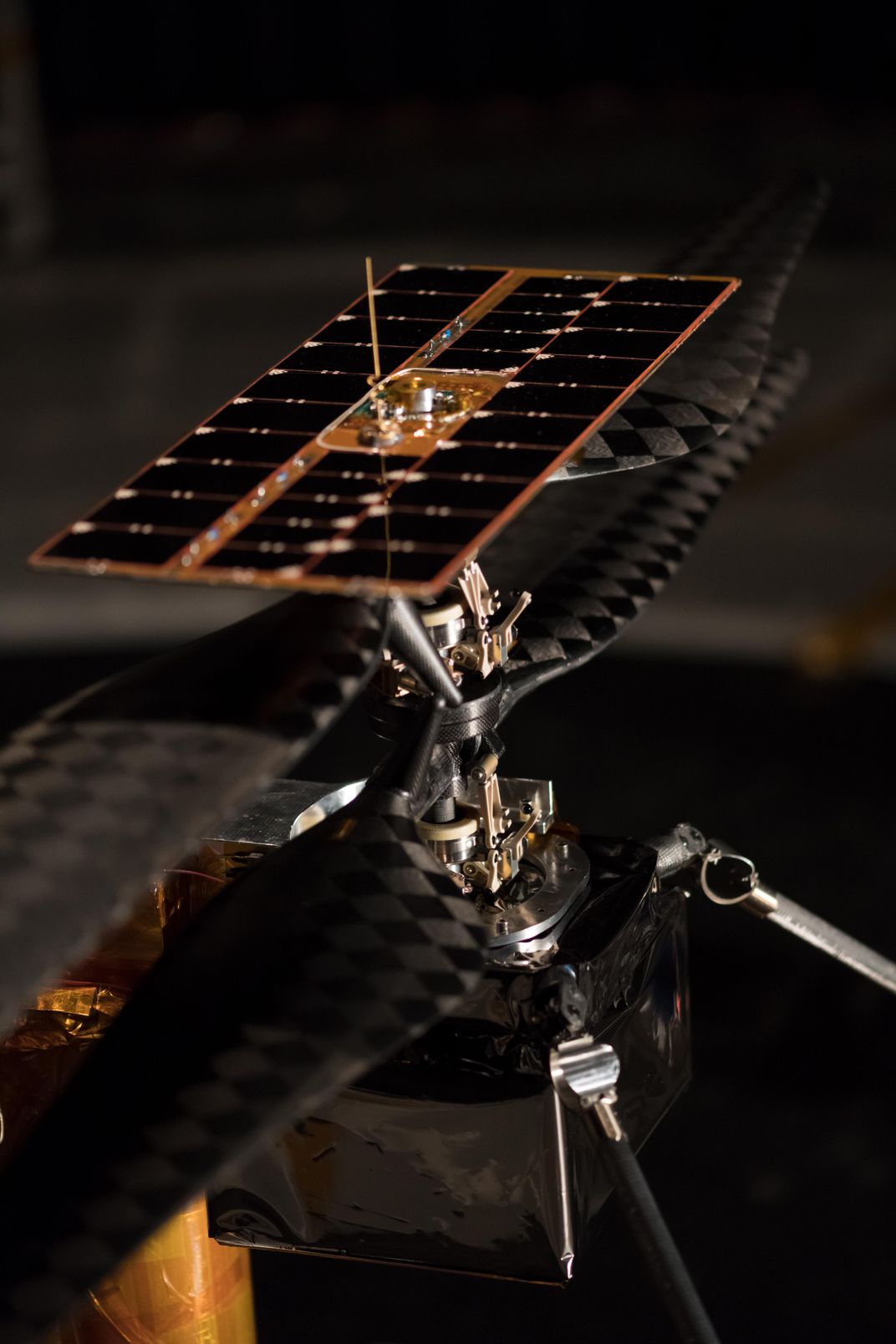

To fit snugly beneath the Mars rover, the team rejected a conventional tail rotor in favor of a co-axial design featuring two horizontal blades rotating in opposite directions to cancel out their respective torque. The rotors are mounted on a central mast. At the top of the mast, a solar array harvests energy for the lithium-ion batteries. At the bottom is a small cube, about two feet square. A smaller hard-shell container inside this fuselage houses most of the hardware (and software). Four narrow but flexible carbon-fiber legs serve as the low-tech landing system.

The helicopter carries eight electric motors. The rotors are powered by a pair of custom-made 23-pole solid-state DC units filled with square copper wire that AeroVironment’s Keennon hand-wound using a microscope—an incredibly tedious process that took 100 hours per motor. The other six motors drive the swashplates attached to each of the rotors. (Swashplates change the angle of the blades to allow the helicopter to pitch, rotate, and yaw.)

The lithium-ion battery system comes from the vaping industry. Cellphone technology provided the high-level processor and the cameras—a 13-megapixel color device for taking high-resolution photos and a black-and-white camera to provide data for the relatively crude visual navigation system. The low-level processor comes from the automotive world; the laser rangefinder, from robotic applications. “This wouldn’t have been possible without commercial off-the-shelf components,” Grip says.

Even so, just about every design solution created a new problem. For example, the blades were made of lightweight carbon fiber so they could be spun as fast as possible. But they had to be beefed up when it turned out that the thin atmosphere on Mars lacked the natural damping qualities that reduce vibration and catastrophic resonances here on Earth. Early on, the team had hoped to save a few grams by fitting the upper rotor with a collective, which controls altitude, but no cyclic, which controls pitch and roll. (The lower rotor has both.) But these plans were scrapped when it became apparent that the helicopter needed more control authority. So the team “sharpened their tools,” as Aung puts it, to reduce weight elsewhere.

In May 2016, Aung and company were confident enough to set the Martian helicopter free in the 25-foot vacuum chamber. To compensate for Earth’s gravity, the model had to be scaled down to 850 grams (1.9 pounds), so the power system, computers, and avionics were removed from the vehicle and connected to the fuselage through a long tether.

The fully autonomous risk-reduction flight went off without a hitch. And yet team members sat stone-faced as they watched. “People said, ‘You guys were so under control,’ ” Aung says, recalling the friendly jibes from colleagues. “But we were so happy. There is no way to describe how we felt.”

The success elevated the program from a blip on NASA’s radar to something worth watching more closely. A new round of funding financed a pair of engineering design models (EDMs), which would serve as the template for the actual Mars Helicopter—if, in fact, NASA decided to build it. But even as construction began, the team discovered that it had miscalculated the thermal budget.

Two thirds of the energy produced by the batteries was earmarked for keeping them warm during the frigid Martian nights, and this proved to be tougher than expected. The solar panel was enlarged, and extra battery cells were added, which meant more weight. Fortunately, Keennon’s motors turned out to be more energy-efficient than projected, which saved some mass. Ultimately, the vehicle weighed a tick less than four pounds.

On January 9, 2018, EDM-1 went into the Space Simulator at JPL. Besides being pumped down to simulate the anemic Martian atmosphere, the chamber was filled largely with carbon dioxide to mimic the Red Planet’s oxygen-poor environment. To simulate Martian gravity, the vehicle was attached to a tether known as a gravity offload system, which essentially gave EDM-1 a helping hand staying aloft. The test flight was a slam dunk. But this time, instead of receiving a figurative gold star from NASA, the team got the brass ring—a highly coveted slot as a technology demonstrator on the Mars 2020 mission.

NASA and JPL scientists have already started brainstorming about the future of Martian helicopters. Aung says the thin atmosphere will probably limit them to 10 to 15 kilograms (22 to 33 pounds), which means they won’t be large enough to carry human beings. But they’ll be fitted with scientific instruments as heavy as two-plus pounds. “Future versions of Mars rotorcraft will be able to perform sustained missions that will cover regions of otherwise inaccessible terrain and to perform ‘surface interactive’ science campaigns such as soil and rock analysis and sample retrieval,” Young says. “Such vehicles could enter craters, could fly near cliff faces or other large rock formations, or do low-altitude surveys of ancient riverbeds and deltas.”

That said, the centerpiece of the Mars 2020 expedition will not be the helicopter but the rover carrying it into space. While the rover’s mission is nominally expected to last nearly two Earth years, the helicopter has been allotted only 30 days to do its thing. The primary goal is simply to demonstrate the feasibility of the concept. Hopes are high, but expectations are not. “We’re not a flagship mission with a billion-dollar budget,” Balaram says. “We are a very lean, small-tech demo—high risk, high fail.”

The batteries limit the flight time to 90 seconds, and there’s enough energy to launch only once a day. Airspeed will top out at 10 meters per second (about 22 miles per hour)—two meters per second of ground speed while allowing for up to eight meters per second of wind—and the altitude will be capped at 16.5 feet. The helicopter’s ability to map terrain is marginal, so it will land on the flat and open spot from which it launched. The most ambitious flight on the schedule calls for the vehicle to fly 500 feet before returning to the launch site.

And after that? TBD. It’s not clear how many cold cycles the components can survive, and there’s no way the helicopter can endure the brutal Martian winter. As Aung puts it, “It’s built to tech demo standards, and it’s not meant to last forever.” Then again, the vehicles JPL has built for Mars have earned a reputation for going above and beyond the call of duty. The Spirit and Opportunity rovers, designed to survive about three months apiece, thrived for six years and 14 years, respectively. So, Balaram says the team has already dubbed the helicopter Wendy.

Wendy? Why Wendy?

Balaram grins and explains: “For ‘we’re not dead yet.’”