Is SpaceX Changing the Rocket Equation?

1 visionary + 3 launchers + 1,500 employees = ?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Visionaries-Elon-Musk-FLASH.jpg)

You can be rich enough to buy a rocket and still get sticker shock. In early 2002, PayPal co-founder Elon Musk, already a multimillionaire at 30, was pursuing a grand scheme to rekindle public interest in sending humans to Mars. A lifelong space enthusiast with degrees in physics and business, Musk wanted to place a small greenhouse laden with seeds and nutrient gel on the Martian surface to establish life there, if only temporarily. The problem wasn’t the lander itself; he’d already talked to contractors who would build it for a comparatively low cost. The problem was launching it. Unwilling to pay what U.S. rocket companies were charging, Musk made three trips to Russia to try to buy a refurbished Dnepr missile, but found deal-making in the wild west of Russian capitalism too risky financially.

On the flight home, he recalls, “I was trying to understand why rockets were so expensive. Obviously the lowest cost you can make anything for is the spot value of the material constituents. And that’s if you had a magic wand and could rearrange the atoms. So there’s just a question of how efficient you can be about getting the atoms from raw material state to rocket shape.” That year, enlisting a handful of veteran space engineers, Musk formed Space Exploration Technologies, or SpaceX, with two staggeringly ambitious goals: To make spaceflight routine and affordable, and to make humans a multi-planet species.

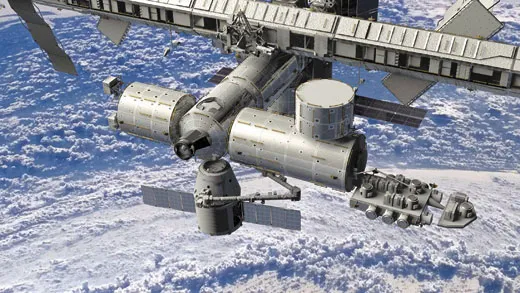

Nine years later, SpaceX employs 1,500 people and occupies a half-million-square-foot facility in Hawthorne, California, that used to produce fuselage sections for Boeing 747s. Today it is filled with rocket parts, including stages and engines for its Falcon 9 boosters, which can place up to 23,000 pounds of payload in low Earth orbit. Off to one side sits a slightly charred, cone-shaped Dragon capsule that a year ago became the first commercial spacecraft to be launched into orbit and recovered. Sometime next year, SpaceX plans to launch the first of 12 Dragons to the International Space Station, each hauling six tons of cargo, under a $1.6 billion resupply contract with NASA. More than two dozen commercial launches are also booked. And by 2015, the piloted version of Dragon is expected to be ready to pick up where the space shuttle left off, carrying astronauts to and from the orbiting outpost.

All very impressive. But what really sets SpaceX apart, and has made it a magnet for controversy, are its prices: As advertised on the company’s Web site, a Falcon 9 launch costs an average of $57 million, which works out to less than $2,500 per pound to orbit. That’s significantly less than what other U.S. launch companies typically charge, and even the manufacturer of China’s low-cost Long March rocket (which the U.S. has banned importing) says it cannot beat SpaceX’s pricing. By 2014, the company’s next rocket, the Falcon Heavy, aims to lower the cost to $1,000 per pound. And Musk insists that’s just the beginning. “Our performance will increase and our prices will decline over time,” he writes on SpaceX’s Web site, “as is the case with every other technology.” Like the Chinese, many observers in this country are wondering how SpaceX can deliver what it promises.

After nearly a decade of struggling to reach this point, Musk isn’t about to reveal the finer details of how he and his privately held company have created the Falcon and Dragon. They don’t even file patents, Musk says, because “we try not to provide a recipe by which China can copy us and we find our inventions coming right back at us.” But he talks freely about SpaceX’s approach to rocket design, which stems from one core principle: Simplicity enables both reliability and low cost. Think of cars, Musk says. “Is a Ferrari more reliable than a Toyota Corolla or a Honda Civic?”

Simplifying something as complex as a rocket is no easy task. And historically, most rocket makers have made their top priority performance, not cost. The space shuttle’s main engines were the highest-performance rockets ever flown, but they helped make the shuttle what Musk calls “a Ferrari to the nth power” that required thousands of worker-hours to refurbish between flights. The Atlas and Delta rockets purchased under the government’s Evolved Expendable Launch Vehicle program serve NASA and Department of Defense customers whose main concern is reliability. “What the EELV program does is launch national reconnaissance satellites that cost billions of dollars a pop,” explains former NASA associate administrator Alan Stern. “[Defense department customers] don’t care whether [the launch cost] is $100 million or $300 million; it’s in the noise. What they want is a guarantee it’s going to work.” And, says Stern, the track records of Atlas and Delta are nearly flawless. “They’re spectacular…. That said, they’re very expensive.”

United Launch Alliance, the consortium of Boeing and Lockheed Martin that produces both the Delta and the Atlas, does not make its prices public. But budget documents show that in 2010 the EELV program received $1.14 billion for three rockets—an average of $380 million per launch. And prices are expected to rise significantly in the next few years, according to defense department officials. Why? Musk says a lot of the answer is in the government’s traditional “cost-plus” contracting system, which ensures that manufacturers make a profit even if they exceed their advertised prices. “If you were sitting at a n executive meeting at Boeing and Lockheed and you came up with some brilliant idea to reduce the cost of Atlas or Delta, you’d be fired,” he says. “Because you’ve got to go report to your shareholders why you made less money. So their incentive is to maximize the cost of a vehicle, right up to the threshold of cancellation.”

That’s a little overstated, says Stern. Yes, rockets are expensive largely “because the system allows it.” But in today’s economy, ULA’s military customers are calling for prices to come down. “I know that they have an incentive to reduce their cost,” Stern says, “but it’s at the margin.” In other words, ULA’s cost-saving efforts are limited by the high overhead associated with traditional ways of building and launching rockets.

Musk says that overhead starts with how the launch vehicle is designed. The workhorse Atlas V, for example, used for everything from planetary probes to spy satellites, employs up to three kinds of rockets, each tailored to a specific phase of flight. The Russian-built RD-180 first- stage engines burn a highly refined form of kerosene called RP1. Optional solid-fuel strap-on boosters can provide additional thrust at liftoff, and a liquid hydrogen upper stage takes over in the final phase of flight. Using three kinds of rockets in the same vehicle may optimize its performance, but at a price: “To a first-order approximation, you’ve just tripled your factory costs and all your operational costs,” says Musk.

Instead, from the very beginning, SpaceX designed its Falcon rockets with commonality in mind. Both of Falcon 9’s stages are powered by RP1 and liquid oxygen, so only one type of engine is required. Both are the same diameter and are constructed from the same aluminum-lithium alloy, reducing the amount of tooling and the number of processes and resulting in what Musk calls “huge cost savings.”

No choice was more critical than the Merlin rocket engines used to power Falcon 9. SpaceX propulsion chief Tom Mueller and his team selected an engine type called the pintle that was pioneered by Mueller’s former employer, TRW, which used it for the descent stage of the Apollo lunar module. Unlike most rocket engines, in which droplets of fuel and oxidizer are sprayed into the combustion chamber through an injector plate resembling a shower head, the pintle uses a needle-like injector that’s more like the nozzle on a garden hose. It’s not only less expensive to make, Mueller says, but it is also less susceptible to combustion instability, a runaway buildup of energy within the thrust chamber that has vexed engineers since the dawn of the Space Age (it added years and many millions of dollars to development of the giant F-1 engines for the Saturn V moon rocket, for example). Combustion instability can make an engine undergo what veterans dryly call an RUD, for Rapid Unscheduled Disassembly; civilians would call it blowing up. Even the Merlin had a couple of RUDs in the early days of development. “There are a thousand things that can happen when you go to light a rocket engine,” Mueller says, “and only one of them is good.”

That, of course, was hardly news by the time SpaceX got started; studies had shown that over the previous two decades, the vast majority of rocket failures were due to engine malfunctions. And so, before attempting the multi-engine Falcon 9, Musk began with the smaller and less expensive Falcon 1, which uses a single Merlin engine in its first stage. Test launches of this 70-foot rocket, beginning in 2006, were SpaceX’s baptism by fire. Only after three failed attempts did the Falcon 1 become the first privately built liquid-fuel vehicle to reach orbit, in September 2008. Musk and his team were both elated and sobered. “We knew it would be hard,” Mueller says, “but it was harder than we thought.”

The rest of the aerospace world took notice. With the early Falcon 1 failures, says Stern, Musk “showed spine, showed he would spend his own money, showed he would stick with it.” And the lessons learned from Falcon 1 smoothed the path for Falcon 9, whose successful maiden launch, in June 2010, impressed observers accustomed to watching other would-be rocket startups, from AMROC in the 1980s to Kistler in the 1990s, fail before getting anything into space.

The Falcon 9 was designed from the beginning to be human-rated, meaning an increased focus on reliability. The rocket’s avionics and controls are triple-redundant (as will be some sensors in the human-rated version of the Atlas V), and the flight computers, which run on Linux, will “issue the right commands even if there’s severe damage to the system,” Musk says. The choice of nine engines for the first stage was made with reliability in mind: From the moment of liftoff, Falcon 9 can suffer an engine shutdown and keep flying; after about 90 seconds, it can tolerate a second engine shutdown. Even if an engine explodes, says Mueller, the others will not be affected.

Of course, SpaceX goes to great lengths to prevent such a scenario. Part of the Merlin’s qualification testing involves feeding a stainless steel nut into the fuel and oxidizer lines while the engine is running—a test that would destroy most engines but leaves the Merlin running basically unhindered. Every Falcon upper and lower stage is test-fired in Texas before it’s cleared to fly. “It’s very common to do component and system-level testing…. That’s very typical in aerospace, ” says Alan Lindenmoyer of Houston’s Johnson Space Center, who has been working with SpaceX since 2005 as manager of the agency’s Commercial Crew and Cargo program. “But to actually put a vehicle together and do system-level testing of the rocket is not. That’s a level of rigor you don’t typically see.” On the pad at Cape Canaveral, Florida, the rocket undergoes an additional brief firing a few days before launch. And just before liftoff, for a few moments after the engines are lit, their performance is analyzed by the Falcon’s computers before hold-down clamps are released and the rocket is allowed to rise.

The Merlin engine itself has undergone a number of improvements, including reducing the number of parts and increasing its power and efficiency. According to Mueller, the 140,000-pound-thrust Merlin 1D, designated the production model for Falcon 9, has the highest thrust-to-weight ratio of any rocket engine ever made.

Significantly, the Merlin engines—like roughly 80 percent of the components for Falcon and Dragon, including even the flight computers—are made in-house. That’s something SpaceX didn’t originally set out to do, but was driven to by suppliers’ high prices. Mueller recalls asking a vendor for an estimate on a particular engine valve. “They came back [requesting] like a year and a half in development and hundreds of thousands of dollars. Just way out of whack. And we’re like, ‘No, we need it by this summer, for much, much less money.’ They go, ‘Good luck with that,’ and kind of smirked and left.” Mueller’s people made the valve themselves, and by summer they had qualified it for use with cryogenic propellants.

“That vendor, they iced us for a couple of months,” Mueller says, “and then they called us back: ‘Hey, we’re willing to do that valve. You guys want to talk about it?’ And we’re like, ‘No, we’re done.’ He goes, ‘What do you mean you’re done?’ ‘We qualified it. We’re done.’ And there was just silence at the end of the line. They were in shock.” That scenario has been repeated to the point where, Mueller says, “we passionately avoid space vendors.”

In a few cases, SpaceX has even been able to advance the state of the art. For the Dragon’s heat shield, the company chose a material called PICA (phenolic impregnated carbon ablator), first developed for NASA’s Stardust comet-sample-return spacecraft. Rejecting the prices they were getting from the manufacturer, they took advantage of help from NASA’s Ames Research Center to make it themselves. According to Mueller, SpaceX’s material, called PICA-X, is 10 times less expensive than the original, “and the stuff we made actually was better.” In fact, says Musk, a single PICA-X heat shield could withstand hundreds of returns from low Earth orbit; it can also handle the much higher energy reentries from the moon or Mars.

Musk, who is SpaceX’s chief designer as well as its CEO, is involved in virtually every technical decision. “I know my rocket inside out and backward,” he says. “I can tell you the heat treating temper of the skin material, where it changes, why we chose that material, the welding technique…down to the gnat’s ass.” And he pushes his people to do more than they think is possible. “There were times when I thought he was off his rocker,” Mueller confesses. “When I first met him, he said, ‘How much do you think we can get the cost of an engine down, compared to what you were predicting they’d cost at TRW?’ I said, ‘Oh, probably a factor of three.’ He said, ‘We need a factor of 10.’ I thought, ‘That’s kind of crazy.’ But in the end, we’re closer to his number!”

Musk’s relentless pushing has paid off. A recent study by NASA and the Air Force finds that it cost about $440 million for SpaceX to get from a blank sheet of paper to the first Falcon 9 launch (a figure, Musk says, which also includes most of the Falcon 1 development). If NASA had done the same thing, with its management structure and traditional use of aerospace contractors, the study finds, it would have spent three times that much.

If SpaceX’s progress sometimes seems like a 21st century replay of NASA’s early history, that’s partly because the company has greatly benefited from the space agency’s vast technical archive. “We’re standing on the shoulders of giants,” Mueller says. “With the Apollo program they learned so much. And we can get access to all that. We use that tremendously. A private company in a vacuum could not do what we did.”

But as for SpaceX’s organizational style, it’s Silicon Valley, not NASA, that had the most influence. In Hawthorne, where everyone including Musk works in cubicles instead of offices to encourage communication, the buzzwords of the business culture—lean manufacturing, vertical integration, flat management—are real and fundamental. Says former SpaceX business development director Max Vozoff, “This really is the greatest innovation of SpaceX: It’s bringing the standard practices of every other industry to space.” Having almost all of SpaceX’s engineers under one roof means the process of designing, testing, and improving is greatly streamlined. One NASA manager who visited SpaceX quips that when there is a new problem to solve, “it looks like a flash mob” in the hallway.

Some observers have questioned whether SpaceX’s smaller workforce can build and operate a vehicle safe enough for astronauts to fly (see “Is It Safe?” April/May 2009). But former astronaut Ken Bowersox, who joined SpaceX in 2009 as vice president of astronaut safety and mission assurance, says safety stems mostly from a vehicle’s design. Bowersox, who flew four space shuttle missions as well as the Russian Soyuz, says that at NASA the shuttle’s complexity required a large organization to manage the risks. “People started to think that that’s the only way you can operate. And I have to say that I would’ve been in that boat if I hadn’t been sent off to train in Russia,” where the workforce is much smaller. Because the Soyuz is far simpler than the shuttle and includes an escape system, he says, it is safer despite the inevitable human errors. Dragon follows the same design philosophy.

Human-rating the Dragon will require development and flight tests of a launch abort system, which could cost nearly a billion dollars. Before astronauts are allowed to fly it, NASA will subject the craft to an intensive review. Lindenmoyer, the commercial crew program manager, thinks Musk and his team can meet the agency’s standards. “Everybody has a perception of SpaceX, what they must not be doing,” he says. “But when you get in there and you’re shoulder to shoulder with them, you quickly learn that that is not the case. Believe me, I was skeptical at first. Do they follow all those standards for quality and safety? Yes, they do. They absolutely do.”

Many of Lindenmoyer’s NASA colleagues remain skeptical—even some who have visited SpaceX. “There’s quality control in development, and then there’s quality control in production,” says one agency senior manager who asked not to be named. “The history of launch vehicle development suggests that design issues might crop up in the first or second launch, but it’s the process problems that start to show up on the sixth, the seventh, and the eighth launch.” Noting that so far Musk’s team has launched only two Falcon 9s, this skeptic asks, “How does he ever get to a rate—you know, he’s talking about flying a dozen, two dozen times a year? And as they fly their vehicle, how long before they have a major accident? And are they able to sustain a major accident and still be a viable company?”

Musk appears undaunted by these worries, maybe because he’s already thinking ahead to bigger ones. He says he is committed to turning Falcon 9 into “the first fully and rapidly reusable rocket” because, he says, that accomplishment is key to making spaceflight affordable and routine. To cut the cost of getting to orbit to just $100 per pound, Musk says, “you need to be able to launch multiple times a day, just like an airplane. And it’s got to be complete, so you can’t be throwing away a million dollars of expendable hardware every flight either.” Musk has targeted reusability from the start. Merlin engines, for example, are designed to fly tens of missions—provided you can get them back. An animation on SpaceX’s Web site shows how that might happen: Cast-off Falcon 9 stages reenter the atmosphere at between 17 and 25 times the speed of sound, then use their own guidance systems and engines to fly back to the launch site, where they land upright on deployable legs. A test program called Grasshopper is already in the works at SpaceX’s Texas facility. No one can predict how many years it might take to achieve full and rapid reusability, but Musk says, “it’s absolutely crucial. It’s fundamental. I would consider SpaceX to have failed if we do not succeed in that.”

The insistence on reusability “drives the engineers insane,” says Vozoff. “We could’ve had Falcon 1 in orbit two years earlier than we did if Elon had just given up on first stage reusability. The qualification for the Merlin engine was far outside of what was necessary, unless you plan to recover it and reuse it. And so the engineers are frustrated because this isn’t the quickest means to the end. But Elon has this bigger picture in mind. And he forces them to do what’s hard. And I admire that about him.”

Musk makes no secret of the end goal: Create a new civilization on Mars. Speaking at the National Press Club in Washington, D.C., in September, he outlined the business plan—if that’s the right term for something that looks decades into the future. “If you can reduce the cost of moving to Mars to around the cost of a middle class home in California—maybe to around half a million dollars—then I think enough people would buy a ticket and move to Mars,” he said. “You obviously have to have quite an appetite for risk and adventure. But there are seven billion people on Earth now, and there’ll be probably eight billion by the midpoint of the century. So even if one in a million people decided to do that, that’s still eight thousand people. And I think probably more than one in a million people will decide to do that.” Talking about a city on Mars by the middle of this century—even as SpaceX has yet to fly its first cargo mission to Earth orbit—is one of the reasons space professionals are skeptical about Musk’s claims.

Meanwhile, SpaceX has the immediate hurdle of converting the doubters with a track record of low cost and reliability. Rivals know that success would hit the rocket business like a tsunami, and at least one aerospace engineer greets that prospect with a mix of hope and doubt. “Honestly, as an American, I want them to succeed,” says Mike Hughes, who works for a company (he asked that it not be named) planning a competing crew vehicle. “If I see SpaceX failing their launches and killing crew, I will be disheartened and weakened…. I want them to be our competition.” But Hughes predicts SpaceX will have to learn the same painful lessons that every other rocket builder has. “Over time, they will experience failure. The failure will teach them that they weren’t so smart when they laid out the numbers at the beginning. Just like us, just like NASA. And they’re going to have to redesign stuff. And they’re going to have to add new tests in. And their schedules will slip, and their customers will suffer. And all of this is because what we do is just freaking hard.”

No one needs to tell the people at SpaceX that they’re pushing the limits of technology. But Alan Stern, for one, remains convinced that Musk is in it for the long haul. “He wants to make people a multi-planet species, and he’s not going to quit. He’ll change the model, or he’ll spend more of his own money—he’ll do something. He’s not in it to build the rockets; that’s a means to an end. It’s a religion for him.”

If Stern is right, when the astronauts aboard the International Space Station receive their six tons of supplies from a SpaceX vehicle launched by a SpaceX rocket next year, they just might be witnessing the first step in a journey to Mars.

Andrew Chaikin, author of Voices From the Moon (Studio, 2009), plans to cover the first commercial lunar landing — as a crew member.