Konnichi Wa, Kibo

The International Space Station says hello to its newest addition, made in Japan.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/kibo-0308-631.jpg)

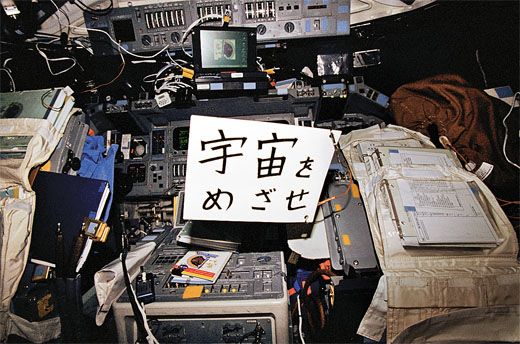

I MADE MY FIRST TRIP TO JAPAN shortly after my first trip to space, on the shuttle Endeavour, in 1996. The main job on that mission had been to retrieve the Space Flyer Unit, a Japanese satellite launched months earlier as a platform to test materials and conduct experiments in orbit. After we returned the satellite to Earth, our six-man crew went on a post-flight tour of Japan, visiting schools, civic groups, and the factories where components of the satellite had been manufactured.

Despite my longstanding interest in Japanese culture, I was unprepared for the warmth and adulation that greeted our shuttle crew. At one school we stepped out of our cars to see a line of 200 children, each holding a bouquet of flowers. In synchrony they rushed up and surrounded us in a gigantic floral arrangement, calling out our names and singing songs as they showered us with the bouquets. I still have some of those flowers.

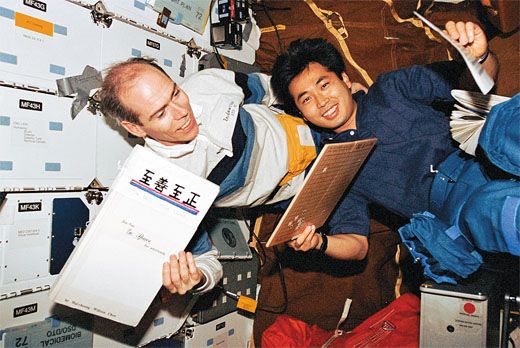

If we NASA astronauts were treated as honored guests, our Japanese crewmate, Koichi Wakata, was a rock star. One evening in Tokyo, we were walking back to our hotel from an embassy party when a group of teenage girls walked by in the other direction. They continued for another 40 feet or so, then turned around and ran back to us, screaming, "Wakata-san, Wakata-san!" When they reached us, they began jumping up and down, screaming and flapping their arms rapidly. We saw this behavior by young girls again and again around Koichi, so often we came to expect the dance and gave it a name: the Penguin.

I've returned to Japan several times since, and in some ways, the country feels to me like the America of the 1950s. At gas stations, attendants surround your car, filling it up, washing windshields, and checking the tires. There are greeters in department stores and someone to push the button for you on the elevator. The taxis are so clean that the drivers wear cloth gloves and the seats are covered in white lace linen. People leave their handbags on the counter when using a public restroom. In Tokyo you can walk safely almost anywhere late at night.

And, like the United States in the 1950s, Japan is embarking on an expensive, long-term program of human space exploration. More than 20 years after joining the International Space Station partnership, the country will finally see a return on its investment when its Kibo ("Hope") laboratory is installed as the station's last and largest module, alongside NASA's Destiny, Russia's Zvezda, and Europe's newly arrived Columbus.

Kibo has most everything you'd want in a space laboratory. Its 37-foot-long pressurized module affords plenty of volume for astronauts to conduct research. An exposed facility attaches like a porch to the outside of Kibo so that some experiments can be exposed to the vacuum of space. There's a separate storage module, and a Japanese-built robot arm, or remote manipulator system, to move equipment from one location to another. A final Japanese contribution, called the H-II Transfer Vehicle, is a rocket-borne cargo container that can deliver supplies or research equipment to the station. The cargo vehicle is scheduled to be launched from the Tanegashima Space Center in southern Japan next year.

During the two decades in which the Japanese have been designing and building this hardware, they have also been assembling a modest astronaut corps. Today there are eight Japanese astronauts, five of whom have already flown on NASA's space shuttle. All have science or technology backgrounds; none came from the world of military aviation.

Takao Doi, a shuttle veteran and one of the first three Japanese astronauts chosen in 1985, will operate the station's robot arm to install Kibo's first piece, the storage module, on the space station this spring (the pressurized module will go up on the shuttle after that, and the exposed facility will be delivered several flights later). Wakata, who has flown in space twice, will be the station's first long-term resident from Japan, arriving this October for a five-month stay.

Japan's first shuttle astronaut was Mamoru Mohri, a materials scientist who flew twice in space and now, at 60, runs the Miraikan science museum in Tokyo. Along with Doi and Chiaki Mukai (who in 1998 was on the same crew with John Glenn during the latter's celebrated return to space), Mohri reported to Houston for training in late 1985. He remembers the culture shock. "Before I went to the Johnson Space Center, I didn't realize there were so many astronauts training," he says. "At that time there were about 150. Every three months a space shuttle was being launched."

Mohri is the most famous of Japan's small band of astronauts, and he appears on Japanese television frequently as a spokesman for space exploration. "For a long time [after his 1992 shuttle mission], I was the only one who had flown," he says. While the news media pay close attention when a Japanese astronaut flies (the most recent was Soichi Noguchi, a former aeronautical engineer who was on the first post-Columbia shuttle mission, in 2005), human spaceflight hasn't gotten the headlines lately that other Japanese space accomplishments have, such as the Hayabusa probe's visit to asteroid Itokawa in 2005, and the high-definition TV images that the Kaguya orbiter recently began beaming back from the moon. The launch of Kibo promises higher visibility for Japan's astronauts, who will now spend months at a time working in orbit inside a Japanese-built module.

For Europe and Japan, the project's junior partners, building the space station has been an exercise in patience. U.S. budget politics and shuttle delays have led to design changes and to shifts in the plans NASA has for its own use of the station. Meanwhile, Japan and Europe have stayed on their original course. The Japanese Aerospace Exploration Agency (JAXA) will launch much the same hardware that its predecessor, the National Space Development Agency of Japan, envisioned in the 1980s. And the list of experiments that Japanese university researchers proposed years ago—some of them follow-ups to Japanese studies conducted on 1990s shuttle/Spacelab missions—has for the most part remained fixed.

"NASA has changed its goal to technology development for [moon-Mars] exploration," says Shigeki Kamigaichi, who manages JAXA's space station utilization program. "But in Japan, our goals still involve basic science," including investigations into crystal growth, fluid physics, cell and plant biology, and the effects of space radiation on various life-forms, including humans.

Kibo brings several unique capabilities to the station, starting with the porch-like facility. The Japanese robot arm will be used to transfer experiments through an airlock so that researchers studying the behavior of materials in space will have a "hard vacuum." Another facility, an aquatic habitat, is proposed for the second phase of Kibo research, to begin after 2010. The aquarium will allow multi-generational studies of species, including zebrafish, a remarkable creature commonly used in developmental biology and genetics experiments because its embryo is transparent, a trait that makes it easier to observe the secrets of cell division and distribution.

Japan will share the Kibo facilities with its international partners. Japanese astronauts will use them only half of the time. Of that allocation, Kamigaichi says a "small portion" will be set aside for non-traditional pursuits, including cultural activities that JAXA created as a way for the Japanese public to contemplate life and the universe. In the "Space Poem Chain," nationally known poets are selecting entries from a competition, and a DVD with the first 24 winning poems will be carried up with Kibo when it is installed. Projects in space dance and art are under consideration too, says Kamigaichi.

JAXA has invited other Asian nations to propose experiments on Kibo, and has held conferences to solicit ideas from researchers in Vietnam, Thailand, Malaysia, Indonesia, and other nations. While these would likely be modest student experiments, South Korea (which is sending an astronaut to the space station this spring) has expressed interest in building a substantial piece of experimental hardware, says Kamigaichi. Such joint ventures could establish Kibo as the Asian—not just the Japanese—sector of the space station.

AFTER MY SECOND SHUTTLE FLIGHT, in 1999, I lived and worked in Japan as the NASA astronaut office's liaison to the Japanese space agency. I was in Tsukuba, a "science city" full of elevated walkways lined with trees and flowers, and it was there that I was introduced to Japanese engineering culture.

On my very first day, I attended a meeting where I learned about Japanese courtesy. I was the only one in the room who didn't speak Japanese, but the entire meeting was conducted in English for my benefit. Even the slides had been translated. I tried to imagine NASA holding a meeting in Japanese because one visitor didn't speak English. Inconceivable. After a week of such special treatment, I resolved to learn enough Japanese to understand the technical talks, despite having always been "language challenged."

At first I was frustrated by the enormous amount of time the Japanese devoted to setting the tone for a meeting or a test. Everyone had to be present and in just the right spot; everyone had to hear the initial briefing, even when (I thought) everyone already knew the material. For every test, there were always at least two video recorders running (somewhere at JAXA there must be a ski slope made of thousands of used video tapes). After a while, though, I came to appreciate that all the preparation made the tests run very smoothly. We never had to wait for someone who was running late. There was never a missing tool. The test equipment always worked correctly the first time.

Bill Jordan worked in Japan from 2000 to 2007, first as the NASA representative to Japan's space agency, then as the NASA attaché at the U.S. embassy in Tokyo. When working with Japanese engineers, he says, " ‘Yes' doesn't always mean yes." He recalls one meeting in which NASA representatives presented a concept for a latching mechanism. "We looked to the Japanese for concurrence and thought we had it," he says. "But sometimes a positive acknowledgment is an indication of ‘I understood what you said,' not ‘I agree with you.' The next day, the Japanese side presented a completely different design, disregarding everything we had discussed the day before." It took several more meetings to settle the differences.

Japanese culture highly values appearance and presentation. Meals often arrive in elegant and creative arrangements on the plate. Reflecting the attention to appearance, Japanese workplaces are exceptionally clean and well organized. Jennifer Goldsmith, a member of NASA's Vehicle Integration Test Team, spent several years in Japan developing space station hardware. She recalls one incident in which her more casual American attitude came into sharp focus. By NASA tradition, any modules built to house astronauts in space are subject to final alterations based on "crew preference," which aren't likely to show up in formal requirements documents. "Once the Kibo hardware arrived in the United States," Goldsmith recalls, "I started to [mark] crew preference [changes] on the JAXA hardware with a Sharpie marker. To see the Japanese technicians' eyes widen at the sight of me writing on their beautiful flight hardware was amazing."

There are institutional differences as well. Unlike NASA, JAXA is not an independent government agency. Its funding comes from the Ministry of Education, Culture, Sports, Science and Technology, but its employees are not civil servants, and there are fewer safeguards against a "revolving door" tradition of employees moving back and forth between government and industry. The relationships between industry contractors and government overseers can be puzzling to Americans. I learned this first-hand, when Kibo's pressurized module was about to be shipped from the Mitsubishi factory in Nagoya, where it was built, to the NASDA space center in Tsukuba in 2001.

Japanese quality inspections conducted during the final phases of manufacturing sometimes have the tone of a religious ritual. Top company executives are on hand along with the engineers and technicians, and attendance by outsiders is strictly controlled. The Mitsubishi representatives suggested that I watch the inspection on a TV monitor in a remote office. I was stunned—had I traveled from Houston to Nagoya just to watch a ceremony on TV? This was supposed to be a real test, not a formality, and it was the last chance to raise concerns about the module before Kibo's hatch was closed and ownership was transferred from the manufacturer to the Japanese space agency. When I pointed out that NASA was required to verify that every bolt and fixture inside the module fit the standard astronaut tools on the space station, I was reluctantly allowed to participate as "Test Subject 2."

"Test Subject 1," I was surprised to learn, was an employee of Mitsubishi, not NASDA. His job was to go through the entire module, methodically fitting tools to every fixture—all under the watchful eye of his boss' boss' boss. Imagine the pressure he felt. One misfit would ruin the ceremony.

The inspection began with each person taking a place around a circle, each place marked with footprints. The hierarchy was crystal-clear. Non-participants stood behind the circle. A reader called out the first fixture and the tool to be used. One guide showed us the fixture as another guide pulled the proper tool out of the box and carefully handed it to Test Subject 1. He fit the tool on the fixture, then handed it to me so I could do the same. We both stated that the tool fit, and the concordance was duly marked by the recorder.

Over the course of many hours, Test Subject 1 and I tried every single bolt, nut, and fixture in the module. The vast majority were absolutely fine, better than most space hardware I have inspected. But every once in a while, Test Subject 1 would fit a tool and hand it to me, and I would have trouble making it fit. The offending fixture was duly noted and marked for repair. In the end, everyone agreed the test was a resounding success.

When I returned to Tsukuba, I asked about the policy of allowing contractors to do their own inspections, and was assured that space agency personnel would conduct a complete inspection once the module arrived at the research center. Of course, repairs would be more troublesome at that point than when Kibo was still at the factory, but to do otherwise could insult the contractor. As for me, at least I had made things less tense. The Japanese could consider the flaws that I found just overzealous pickiness by the NASA guy. And, even though repairing them really was required, it could be construed as a favor, not a reflection of deficient manufacturing.

None of this is meant as a criticism of Japanese space engineering. In fact, JAXA and its predecessor agencies have a solid record of successes, going back to the 1970s, in launching spacecraft for astronomy, solar physics, and Earth observation. But the switch from building satellites to building hardware for human spaceflight, with its more stringent safety requirements and need for tight coordination, is difficult for any nation, including the United States and Russia, which, nearly 50 years after their first spaceflights, still make the occasional mistake. And Japan has proven no exception.

My own shuttle mission, STS-72, offered a small example. While the Space Flyer Unit was a remarkable satellite and ultimately a success, it did have glitches. The first hint of trouble came when its solar arrays jammed while retracting. We had to jettison them, which took valuable time; the satellite could last only about an hour on battery power after the arrays were shut down. Without power, the onboard heaters would fail, causing the satellite's propellant lines to freeze and rupture. We couldn't bring a propellant-spilling satellite into the shuttle's bay; we'd have to abandon it.

Koichi Wakata had the job of using the shuttle's robot arm to bring the spacecraft into the cargo bay. All was going well until the last step, when the satellite wouldn't engage the locking latches. We could get two or three to lock, but not the required four. As he tried over and over, Koichi was the picture of cool concentration—no panic in that guy. But time was running out. Finally, with just five minutes of battery life remaining, he turned to us and said, "Here goes a slam dunk; be ready with those latches!" He revved up the arm and brought the satellite down like Karl Malone going to the basket. Sure enough, four latch lights lit, and we returned the satellite safely to Earth.

What had gone wrong? We never found out for sure. Most likely, a combination of weightlessness and exposure to the hot-cold cycles of space had slightly warped the satellite frame. We were lucky the warping was within the margins of what the latches could accommodate. It was another lesson in the complexities of space hardware, which—especially on large projects—often has to fit parts fabricated in different places at different times.

Nowhere is this more true than on the space station, the largest orbital construction project in history. The station's pieces were built in multiple countries, and the assembly will take more than a decade. New modules like Kibo and Europe's Columbus have to attach to U.S. and Russian modules that have been in space for years. To complicate things more, the station is pressurized, and adding or removing air can change the shape and stiffness of the modules, which have a hull thickness of just 1/16 of an inch. All of these factors raise the same concerns about hardware compatibility we had experienced with Japan's Space Flyer Unit.

Japan finds itself playing a different role than it did on past shuttle flights. Even when the science experiments were Japanese, the vehicle—and the overall mission responsibility—were NASA's. Now, as a full partner in the station program, JAXA will control Kibo from the Tsukuba Space Center in Japan, just as NASA controls its segment from Houston, Russia controls its segment from Moscow, and Europe runs the Columbus module from outside Munich. With the lives of astronauts at stake, decisions will have to be made jointly, but quickly and efficiently. On the first Japanese assembly flight, Mayumi Matsuura will be in Tsukuba as the lead flight director for Kibo. "This is the first time for us to deal with minute-by-minute operations on a daily basis," she says.

To prepare for these duties, JAXA flight controllers have been participating in simulations with their international counterparts, learning how to make routine decisions and handle emergencies. Things don't always go smoothly, according to Mohri, who has been involved in some sessions. "Compared to NASA, JAXA is immature still," he says. When Japanese controllers fail in these simulations, it can be awkward, he admits. Still, every spacefaring nation has had to walk the same road. "Always we are learning," says Kamigaichi, who is confident any problems will be worked out.

The learning curve extends to training astronauts on the ground, which has its own risks. I know that from direct experience. Several years ago I had an opportunity to try out a new Japanese underwater tank built by JAXA for spacewalk training. The pool is similar to the one used to train astronauts at NASA's Johnson Space Center in Houston, but is smaller and designed specifically to accommodate Kibo.

During one run to evaluate the setup of Kibo's pressurized module and the placement of outside payloads, I was methodically moving along the border of the exposed facility when I felt a sudden depressurization of my spacesuit, followed by the feeling of water pressure squeezing my legs like giant blood pressure cuffs. I sank so fast that my two safety divers were unable to catch me. Within seconds I was at the bottom of the 34-foot-deep pool. Water pressure was now pushing my soft body up into the hard parts of the suit and helmet. That put severe pressure on my diaphragm, causing pain and making it very difficult to breathe.

Suddenly I was surrounded: A flurry of cameramen and utility divers joined the safety divers to lift me from the bottom. It seemed to me to take only five or 10 seconds, but later review showed I was at the bottom for a minute and a half.

As it turned out, a technician had mistakenly turned a valve that allowed the suit to depressurize. He came to me the next day and apologized profusely. I assured him that no harm was done and that in the world of spaceflight, training accidents are part of the risk we accept. But I remember thinking that this was the sort of accident that occurs early in the life of a facility. NASA's underwater tank has occasional hardware failures, but there are very few procedural errors. The hard lessons were learned years ago.

Mohri says that although the Japanese public approves of space exploration, if the government is to continue funding space ventures, Kibo must produce "clear results" to show that the roughly $9 billion invested in the space station was not wasted. Those results could come in the form of scientific progress. Mohri, though, sees another, perhaps more important, benefit coming from the country's space station participation. He views Kibo as a kind of political laboratory, where the four major partners—the United States, Russia, Europe, and Japan—have to learn to compete and cooperate at the same time. Each will pursue its own goals, but in an emergency, they'll have to pull together and make decisions for the common good. "If something wrong happens inside Kibo, then four ground stations have to talk about whether we abandon the module or not, and how they can help," he says.

Mohri has been preaching the value of the space station as "a case study of how we can work together to save Earth." If the idea catches on, then perhaps Japan, the partner whose learning curve has arguably been the steepest, will have discovered the project's true purpose.