Meet the Orbiters

A fleet of winged spacecraft, the likes of which we’ll never see again.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Meet-the-orbiter-631.jpg)

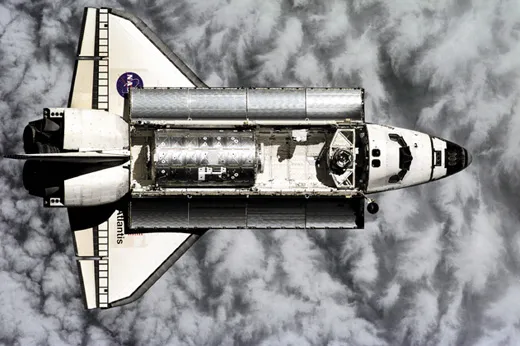

The principle of form following function may never find a truer expression than in the space shuttle. Its designers started with the cargo it would carry — an Air Force satellite 60 feet long and 15 feet in diameter — and built the ship around it. And since the ship was intended to leave its cargo in orbit and return to Earth, onto the payload bay the engineers attached a graceful delta wing and vertical tail. As delivery trucks go, this one sure was elegant.

The blunt nose was a compromise between a pointy jet nose cone to slip through the atmosphere and a capsule belly optimal for reentry. The gray nose cap and tuxedo-like stripe along the wing leading edges were composed of reinforced-carbon-carbon blankets, smoother and more aerodynamic than the black ceramic tiles near the nose cap and on the “jawline”—the forward-most part of the wing edge, where it meets the fuselage, just behind the cockpit. Tile also covered the leading edge of the vertical tail. These areas tolerated the 3,000-degree-Fahrenheit temperatures that reentry generated there. A black-tiled belly, a precisely engineered mosaic of unique tile shapes and thicknesses, also protected the vehicle against the blistering heat.

The five orbiters NASA built became the most complex fleet the world has ever seen: Columbia, Challenger, Discovery, Atlantis, and Endeavour. Enterprise, which preceded them all, looked like an orbiter but flew only atmospheric approach and landing tests. (In the late 1970s, it was carried on the back of a 747 to altitudes up to 30,000 feet and released to glide back to the runway or dry lakebed at California’s Edwards Air Force Base.) Two orbiters were lost: Challenger in January 1986 during ascent (see “The Real Heavy Lifting,” p. 56), and, 17 years later, Columbia, during its return to Earth.

The spacecraft got their names from naval vessels of exploration: Columbia, from one of the first U.S. Navy frigates, which, in 1836, circumnavigated the globe; Challenger, from a Navy ship that explored the Atlantic and Pacific Oceans for four years beginning in 1872; Discovery, from several British ships, including one Henry Hudson used to discover Hudson Bay; Atlantis, after a ketch operated for the Woods Hole Oceanographic Institution from 1930 to 1966; and Endeavour, built as Challenger’s replacement, from the ship James Cook sailed to the South Pacific in 1768 to see Venus passing between Earth and the sun.

Retired shuttle engineer Tom Moser says the space shuttle’s design was to a large extent determined by the craft’s intended military service. Moser worked for NASA from 1963 to 1989, and was the head of orbiter structural design as well as orbiter deputy project manager before moving higher within the agency. “I had the privilege of working on the shuttle from sketch pad to launch pad,” he says. “We looked at smaller orbiters, orbiters with less wing, straight wings, delta wings.”

The engineers chose delta wings because Air Force planners wanted the shuttle to maneuver as far as possible to either side of its flight path once it reentered the atmosphere, a capability called cross range. They envisioned a vehicle with a lot of mission flexibility, able to quickly return from orbit and land at various secure military airfields. One mission concept involved a shuttle that would launch from Vandenberg Air Force Base, California on a polar trajectory, rendezvous with a reconnaissance satellite, service it, and return to Vandenberg, all in one 90-minute orbit. But Earth’s rotation would carry Vandenberg more than 1,200 miles east during that orbit. So the final cross-range requirement came in at around 1,200-plus nautical miles. (After the Challenger accident, the Air Force dropped plans to launch from Vandenberg.)

Although an Air Force requirement also dictated the dimensions of the payload bay, Moser didn’t know at the time exactly what the payload would be. Today it’s known that the Air Force expected the shuttle to deploy a series of Keyhole photographic imaging and Lacrosse radar imaging satellites, each of which, the service estimated, could weigh as much as 65,000 pounds. (In the end, the shuttle never carried more than 50,000 pounds.) “A lot of that stuff was classified,” Moser says, “so us guys designing the orbiter didn’t know what was driving it. We were just told: ‘This is it.’ Which was fine, because we were designing a truck. We didn’t need to know what the cargo was.”

While a payload requirement of 32 tons may sound like a lot, the Saturn V had already put more than 142 tons into low Earth orbit. But Saturn didn’t have to bring any of it back. The shuttle was designed to not only deploy and service satellites but also, if necessary, retrieve them. In addition, it would have to be able to land with a maximum payload if the crew were forced to abort during ascent.

Despite the advances needed for such a revolutionary vehicle, the airframe was built from a conventional material—aluminum. More advanced metals had been used in high-speed vehicles— in the 1960s, the Mach 3 Lockheed SR-71 spyplane, for example, was built of titanium. But during a shuttle reentry, starting at about eight times the top speed of an SR-71, temperatures would quickly exceed what even titanium could tolerate. So its only advantage, compared to aluminum, was slightly lower weight. Once the shuttle was coated with ceramic and carbon-carbon, says Moser, a titanium frame’s weight savings was negligible, while its cost—2.5 times more than aluminum—wasn’t. Add to that the difficulty of working with titanium, which could be so hard under certain conditions that tooling couldn’t drill through it properly, and it looked even less attractive. Moser recalls the day that he and other structural engineers visited Kelly Johnson’s Lockheed Skunk Works in Palmdale, California, where the SR-71 was built. “At the end of a full day of reviewing the pros and cons of titanium, we asked Johnson’s people: If they were us, would they design the orbiter using aluminum or titanium? They answered, ‘Aluminum.’ ”

Shuttle engineers were creating structures that had never gone to space. “The payload bay doors are one of the more interesting structural components on the vehicle,” says Dennis Jenkins, a contract engineer at the Kennedy Space Center in Florida who has worked on the shuttle for more than three decades and who wrote a definitive reference work on the spacecraft. “They can’t even survive in 1 G. They’re extremely fragile—just one layer of Nomex honeycomb composite [a graphite epoxy material]. If you ever look at pictures of it in the Orbiter Processing Facility, you’ll see great big yellow metal frames on the doors, and that’s because we can’t open the doors down here without those. The doors just bend and twist too much, so we have to strengthen them on the ground.” (Jenkins is updating Space Shuttle: The History of the National Space Transportation System to include the program’s final missions.) “[The doors were] actually one of the first aerospace uses of complete composite construction,” he says.

Just the fact that the doors were a mechanical element caused concern in the design phase. “All through the human spaceflight program, we had a lot of problems with mechanisms in orbit,” says Moser. “Closing the doors in Gemini [after a spacewalk] was a problem, as was the docking system in Apollo. Mechanical systems inherently cause problems.” Temperature swings occurring as the shuttle moved between sunlight and shadow, for example, caused surfaces to expand and contract, which interfered with the proper closing of a door or panel. The payload bay doors had to open reliably not just to release a payload, but more immediately upon reaching orbit to expose radiators that shed heat, cooling the vehicle. Worse, at the end of a mission, says Moser, “you couldn’t bring the vehicle back if the doors weren’t closed.” Aerodynamic forces would tear the aft bulkhead off the vehicle.

So engineers made the doors flexible, and pulled them shut with a series of latches along the edge of the bulkheads at each end of the payload bay. “We literally zip it closed,” says Moser. “If they were rigid, that would be a lot more difficult.” Once the doors were closed, four more latching mechanisms along the centerline, where the doors meet, secured them for reentry into the atmosphere.

The flexibility that solved one problem, however, caused others. For example, during flight, the shuttle endured a variety of “loads,” or external forces. Loads come from the atmosphere (aerodynamic loads), the weight of the vehicle and its payload configuration (inertial and structural loads), and even the noise of the engines (acoustic loads). Loads result in vibrations, oscillations, and a bending of the vehicle’s body. Wobbly payload bay doors would be of little use in strengthening the shuttle against breaking apart under these stresses. Unlike the fuselage of an airliner, which is fortified all the way around the circumference of its airframe with longerons (stiffeners that run lengthwise), the shuttle’s fuselage was a cylinder with the dorsal half removed—a convertible, so to speak. Longerons existed in the lower half of the fuselage only. These were made extra robust and, along with the vehicle’s skin attached to them, shouldered the flight loads for the whole fuselage.

Design of the crew cabin required further creative thinking. The cabin was a self-contained, pressurized vessel that sat in the forward fuselage. The only loads it carried came from its internal air pressure and its own weight during launch and landing. “It’s attached [to the interior of the fuselage] at discrete hard points,” says Moser. “It floats. No matter how the fuselage wants to bend or react, that cabin doesn’t enter into sharing the loads with the fuselage.” This design offered fewer chances for the pressurized area to leak in orbit, and simplified pressure testing of the cabin before launch. But because the crew compartment wasn’t built to the same rugged standard as the hull around it, Moser says its design refutes a possibility raised by the Challenger accident investigation: that after the orbiter broke apart, the crew cabin may have remained intact, with the astronauts possibly alive all the way to the water. “I don’t believe that for a heartbeat,” he says. “It was not designed for it. That thing could not have come out of the fuselage without ripping the cabin apart.”

The design principles that protected the crew cabin were also applied to the payloads the orbiters carried. As the vehicle encountered buffeting on the way to space and back, its exterior flexed independently around both payload and crew.

Inside, too, the orbiters were standardized, with a flight deck that sat four crew members and a mid-deck that could carry up to four more. (On only one mission, STS-61A in October 1985, did an orbiter—Challenger—carry eight astronauts; most carried seven.) Astronaut Jerry Ross had spent time in the U.S. Air Force as the chief test engineer for the B-1 bomber, also developed by Rockwell International (now part of Boeing) at about the same time the company built the space shuttle. Construction began on Columbia only six months before the B-1’s first flight. Ross recalls that the flight decks of the orbiter and the bomber had a striking commonality, with their side-by-side seating. “The cockpit arrangement, the instruments, the layout, everything—it was incredibly similar,” says Ross. “The B-1, I had 150 or 160 hours flying in it. And the first time I got into our simulators down here [in Houston], I went, ‘Holy cow.’ It was really quite amazing.”

Starting in 1998 with Atlantis, each orbiter received a major upgrade, the Multi-function Electronic Display System, a so-called glass cockpit that replaced dozens of dials and gauges with 11 flat-panel, liquid-crystal color displays. The new cockpit weighed less, used less power, and reduced glare in bright sunlight, all while offering better views of data from a wide range of angles.

Ross was the first person to be launched into space seven times, all on the shuttle. He flew five missions on Atlantis. “The thing about Atlantis is that to me it seemed to have a little bit stronger buffeting [than the other orbiters] during the transonic Mach, right around Mach 1, coming back in to land,” he says. “It felt like you had run off the tracks and were riding on the railroad ties. It was just a real rough ride for just a little bit.” He felt some of this on Columbia and Endeavour, but it was more pronounced on Atlantis, he says. The crew brought it up in debriefings, but it always remained a mystery.

Franklin Chang-Dìaz, the only other seven-time shuttle flier, flew on every orbiter but Challenger. “Columbia tended to rattle a bit more on liftoff,” he recalls. “Structural integrity was always on my mind, particularly on ascent and reentry.” After years of training as a mechanical engineer with a Ph.D. in applied plasma physics, he couldn’t help thinking about the extreme heating and cooling the orbiter tolerated as it passed every 90 minutes from day to night and back to day. “It reminded me of the way one makes a steel wire break by twisting it until it fatigues away,” he says. “But at the end of the day, I would walk away in awe at the machine that kept me warm and cozy and safe so many times in such an inhospitable place.” After all, each orbiter was designed to operate for 100 missions.

Was there anything he would have changed about the orbiter? “The idea of sending crew and cargo together has never been my favorite,” says Chang-Dìaz. “I would have concentrated on a solely human vehicle and sent the cargo in a robotic craft. But this is all 20/20 hindsight, and considering the compromises that every major space program has had to accommodate, the end result was a technological achievement of the first order.”

Standardization was key to the shuttle’s purpose. “All the vehicles look basically the same,” says Ross. “There are some relatively minor differences. Obviously, Columbia being the first and the heaviest was probably the most significant difference.” Engineers erred on the side of caution, reinforcing Columbia’s airframe more than needed; it ended up 7,000 pounds heavier than the other orbiters. The extra weight disqualified it for later flights to the International Space Station. Because of the station’s high inclination—51.6 degrees from the equator—NASA had to sacrifice the launch boost provided by the spin of Earth. For each degree north in a launch trajectory, an orbiter had to leave about 500 pounds of payload at home. Columbia could have reached the ISS, but it wouldn’t have been able to bring much. Instead, it traveled to lower-inclination destinations, such as the Hubble Space Telescope, orbiting at 28.5 degrees.

Story Musgrave is the only astronaut to have flown aboard all five orbiters. “Columbia, I always viewed her as sort of the queen of the fleet,” he says. “Columbia was the first of the five to climb into space and the one that could orbit Earth the longest. It had more oxygen and hydrogen tanks. And so for every long-duration mission, it was Columbia that flew it. Because it turns out the limiting factor on all the flights was electricity.” On Musgrave’s sixth and final mission, STS-80, which launched in November 1996, the crew set a record for the longest shuttle mission: 17 days, 15 hours, 53 minutes, and 18 seconds.

Few astronauts have ever complained about the shuttle’s close quarters. And “close” is a relative term. Discovery, for example, offered 2,325 cubic feet of habitable volume, versus 316 for the Orion capsule that NASA proposed as the spacecraft after the shuttle, or 36 cubic feet inside the Mercury capsule.

“I loved to sleep on the flight deck,” recalls Ross. “But some commanders would not allow it, or some missions were 24-hour operations.” He would try to sleep during the night pass, he says, and wake for the day pass “to see parts of the Earth we would not have seen otherwise because of the orbit we were in.” It was also cooler on the flight deck, which had strong flows of fan air, he recalls.

His favorite spot, though, was being in the airlock, “when we were preparing equipment and getting suited for an EVA” [extravehicular activity, or spacewalk]. He made nine spacewalks.

Ross’s favorite aspect of the shuttle is its reusability. “That’s a pretty incredible accomplishment in and of itself,” he says. “I think another is the incredible capabilities that it gave us to take payload into orbit, to capture things or mate up with things in orbit, to do spacewalks, to do construction.

“The two biggest drawbacks to the vehicle were, one, it has all its reentry protective shields exposed to the launch and on-orbit environment, the RCC blankets in particular, which is the most critical part. The other thing is that its complexity did require a lot of on-the-ground work to get it ready to go each time. It was far from being the commercial airliner, fill-it-up-with-gas-and-go-again kind of thing. But for a first time, this kind of vehicle really was an amazing capability.”

Former mission specialist and three-time flier Mike Mullane loves to talk about living in the shuttle: “One thing that always surprised me about being in space in the orbiter was how the volume above your head became usable.” In his book Riding Rockets, Mullane recounts the first scheduled sleep period of his first mission. Once everyone was asleep in the mid-deck, he floated up to the flight deck and fixed his sleep restraint beneath the windows that were effectively Discovery’s sunroof. As the autopilot kept the orbiter flying along on its back, tail first, Mullane gazed down at the great sphere of Earth passing by. He barely slept.

Like Chang-Dìaz, Mullane has changes he might have suggested during the design phase, such as a better escape system than the telescoping bail-out pole installed after Challenger, good only at subsonic speed below 30,000 feet. “But I’d fly the shuttle tomorrow without an escape system,” he says.

Perhaps this is the lasting impression that the space shuttle will leave behind: That of a marvelous, dangerous creature with astronauts willing to take the risks to enjoy the adventure.

“The orbiter is a completely different vehicle than anything that has ever flown in space,” says John Shannon, program manager at the Johnson Space Center in Houston. “It was a work platform, a spacewalk platform, a construction site with a robotic arm, a laboratory, a people mover. It was a complex vehicle operating at the edge of its performance, with very little margin for error.”

With each flight, NASA not only launched a crew to complete a mission but also gathered important information on high-Mach, or hypersonic, aerodynamics in a little-understood environment. “There are a lot of areas where we do not understand perfectly all of the physics that are going on. And the shuttle’s been a good vehicle for testing a lot of that out,” says Shannon. The agency will analyze data from the last mission just as it did all the others; to do otherwise “and think we know everything would be a huge mistake,” Shannon says. “We’re going to have a lot of interesting data. And how does this directly tie to the next program? Well, you don’t know because you don’t know what the next program is.”

Whatever does come, the engineers of tomorrow will almost surely reminisce that there was only one space shuttle. Five, actually.