Mr. Fix-It

Frank Cepollina takes repair calls to new heights.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/MrFix%20Space%20FL.jpg)

After 20 years in orbit, service calls to the Hubble Space Telescope seem so routine that it’s hard to believe they were once considered heroic. But after seven space shuttle astronauts first visited the telescope in 1993 to correct its flawed optics—a mistake that had embarrassed NASA, saddened astronomers, and angered Congress—the shuttle crew and managers at three NASA centers were given a trophy. The National Aeronautic Association cited them for “outstanding leadership, intrepidity, and the renewal of public faith in America’s space program.”

Frank Cepollina wasn’t mentioned by name, but his colleagues are quick to give him credit. As head of Hubble servicing at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, Cepollina took the lead in planning that first, and still most important, Hubble repair. Cepollina “is one of the most innovative, brilliant guys I’ve ever worked with,” says Jim Crocker, who was then an engineer at the Space Telescope Science Institute, where he designed key elements of the 1993 mission. According to Crocker, if it hadn’t been for Cepollina, there likely would have been no fix for Hubble.

Cepi, as he is known in the aerospace industry, has for more than 30 years been the world’s leading advocate for servicing satellites in orbit. He had his first success when astronauts repaired the Solar Maximum Mission spacecraft in 1984, and for nearly two decades he has overseen service calls to Hubble, among the most complicated space missions ever flown.

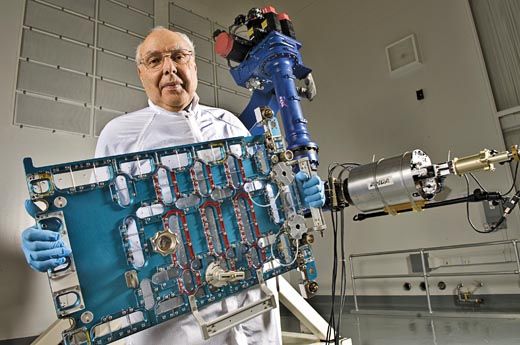

With the completion of the space telescope’s fifth and final upgrade last year, you would think the 73-year-old Cepollina would be ready to call it quits. Retirement, though, is the furthest thing from his mind. As he hustles around his Goddard lab, showing me various Hubble repair tools his team developed, he describes his plans for the future, including an audacious project to have robots refuel spacecraft in orbit. “My plan is to develop a national capability to repair and maintain satellites, anywhere and in any location in space,” he explains.

A cheerful man who can overwhelm you with his enthusiasm, Cepollina was raised on a farm in Alameda, California. His job as a child was to maintain the tractors. “I used to have fun taking things apart and seeing how they worked,” he says. In high school, he set his sights on an engineering career. His grandparents, Italian immigrants who believed in hard work and education, were a big influence. “My grandfather always used to tell me, ‘You never want to work with your hands.’ And my grandmother added: ‘You want to go to college, learn a profession!’ ”

Cepollina earned a bachelor’s degree in mechanical engineering from the University of Santa Clara in 1959, got an Army commission, and went to work for the Army Security Agency in Warrenton, Virginia, not far from Washington, D.C. His work brought him into contact with engineers at Goddard, who were building some of the first unmanned space science probes. “This struck me as being more fun,” he says. “I thought the people [at Goddard] weren’t afraid to try new things, weren’t afraid to push new technology.” In 1963, he moved to NASA.

In those early days, it wasn’t certain that humans could do useful work in space. Not until Buzz Aldrin’s Gemini 12 flight in 1966 did an astronaut demonstrate the ability to do detailed technical tasks during a spacewalk. Still, Aldrin needed an enormous amount of training to perform simple exercises such as turning a bolt, connecting plugs, and cutting wires.

Around the same time, Cepollina was moving from one Goddard science project to another. Most were failures. His first NASA mission was the Advanced Orbiting Solar Observatory, which was cancelled in 1965 before reaching the launch pad. Then came the Orbiting Astronomical Observatory program, which was planned as a series of four space telescopes. The first OAO failed shortly after launch, and the third never reached orbit because its rocket shroud failed to jettison.

That wasn’t uncommon in the 1960s. Approximately 30 percent of NASA spacecraft failed within 10 days of launch. “Some would go in the drink, some the boosters would blow up,” Cepollina remembers. “Some would go up, get turned on for a few hours, and then die.”

In the early 1970s, George Low, NASA deputy administrator and one of Apollo’s guiding lights, was pushing the agency to make its spacecraft more reliable and less expensive. Cepollina’s boss, Joseph Purcell, put together an ad hoc committee to look into the problem. The committee suggested that if spacecraft design was standardized and satellites were built with modular components, NASA could save time and money.

With Purcell’s enthusiastic support, Cepollina took the notion and expanded it, conceiving the idea of designing separate modules for attitude control, power, data handling, and the like—functions required on every spacecraft. These plug-and-play units could be installed on any satellite, and they would be easy to replace.

Cepollina’s Multimission Modular Spacecraft (MMS) program built half a dozen science satellites in the 1970s and 1980s, including the Solar Maximum Mission spacecraft to study the sun, Landsats 4 and 5, the Upper Atmosphere Research Satellite, and the Extreme Ultraviolet Explorer.

To most people, the modular spacecraft program made engineering and economic sense. But for NASA managers in charge of new research satellites, the modular approach limited their flexibility and stole some of their glory. “Their whole goal was to develop and build a new spacecraft, using the newest technology,” explains Joe Rothenberg, who was then working for Grumman but later became Cepollina’s boss at Goddard. “Many project managers were always fighting with him.”

The resistance didn’t faze Cepollina. “You keep your nose down, keep driving the frigging car,” he says. He worked hard, and demanded the same from his employees. “If you didn’t do a good job you wouldn’t be working long on Cepi’s projects,” remembers Elmer Travis, a former Goddard engineering branch chief who’s now retired. Cepollina “was not a typical government employer. He came to work at 7 a.m. and would be there until 10 at night. Then when he went home he never stopped working. He would call me at 11 o’clock at night, wanting some help on a problem.”

David Martin, who worked for Cepollina from 1988 to 1994, says: “Frank was and remains one of my heroes. Everybody who works at NASA should work for him for a while.” But, he adds, “To be honest, you can burn out.”

As the MMS program was getting under way in the early 1970s, the space shuttle program was also gearing up, and the two seemed perfectly matched. “We realized we could take advantage of the shuttle’s two-way capability,” Cepollina recalls. If a satellite component failed, the shuttle could return the spacecraft to Earth, where it would be a simple matter to swap modules. From there it wasn’t a big leap to in-orbit servicing. Why bring the satellite back when the replacement could easily be done by a spacewalking astronaut?

Amazingly, NASA managers were not interested in the idea at first. Goddard’s focus was on reducing the cost of satellites and increasing their reliability, and there was no money for servicing missions. Then Solar Max failed. The mission had been launched in 1980 as the first of Cepollina’s modular spacecraft; its job was to observe the sun at the peak of its 11-year cycle, and it had been designed to be retrieved by the shuttle.

Only nine months after the satellite was launched, however, three fuses in its attitude control system module failed. Shortly after that, a coronagraph-polarimeter designed to study the sun’s corona suffered an electrical failure. Though the spacecraft had been built with plug-and-play subsystems, NASA management was uninterested in a repair mission. Some feared it would be a waste of money: What if something else on the spacecraft failed soon after the repair? More importantly, there was no money for a fix; paying to repair Solar Max would have delayed or canceled some other project.

To Cepollina, not doing the repair when it was feasible was unacceptable. He began calling reporters, letting them know that the spacecraft’s repair would be a trivial matter. “He was not beyond going to the press,” remembers Rothenberg. “His ideas would be in the papers before anybody in the NASA management chain even had a chance to approve it.”

The outspokenness got him in trouble. “I can’t tell you the number of times his boss, including me, had him on the carpet, telling him to cease and desist,” adds Rothenberg. “He’d walk out of the room dejected, go home to sleep it off, and then return the next day as if he never heard what his boss said.”

Cepollina knew that if he could marshal public and Congressional opinion without causing harm to his superiors, they would eventually go along. Sure enough, NASA headquarters finally approved the repair mission, with Cepollina in charge.

He remembers it as the most terrifying time in his career. The future of in-space servicing, an idea he had promoted for years, hinged on this one flight. And immediately after space shuttle Challenger rendezvoused with Solar Max on April 8, 1984, the plan started to unravel. Astronaut George “Pinky” Nelson donned a Manned Maneuvering Unit backpack and flew from the shuttle to the satellite, but was unable to capture Solar Max with a specially designed piece of equipment (it turned out later that a grommet on the satellite—which didn’t appear in blueprints—blocked the docking mechanism).

After three attempts, Nelson succeeded only in setting the spacecraft tumbling. It took a series of hastily prepared software uploads by the ground, combined with a bit of luck when the nearly dead spacecraft drifted into sunlight just long enough—10 minutes—to charge its batteries, to stabilize the spacecraft so that the Challenger astronauts could grab it with the shuttle’s robot arm and haul it into the cargo bay. Finally back on script, Nelson and crewmate James “Ox” Van Hoften breezed through the repair. “They had to do two days’ worth of stuff in one day, and they finished it all,” remembers Barbara Scott, who was the payload operations engineer for the repair mission and is now the Hubble Flight Software manager at Goddard. As a result, Solar Max operated for another five years, recording more than 12,500 solar flares. Just as significantly, the failed attitude control module was returned to the ground, refurbished, and installed on another spacecraft, the Upper Atmosphere Research Satellite. That spacecraft was launched in 1991, and operated in orbit for 14 years. “Second-hand Rose,” Cepollina quips.

The Solar Max repair gave NASA confidence in its plan to send astronauts to Hubble periodically to replace cameras and other scientific instruments with more capable ones, just like an observatory on the ground. For the first Hubble service mission—which also corrected the telescope’s out-of-focus mirror—the Goddard team came up with procedures for replacing three failed gyroscopes, two electronic control units, and eight fuses.

Later missions have replaced Hubble’s instruments and gyroscopes several times over, installed a more powerful set of solar panels to replace the ones brought up in 1993, replaced the telescope’s computer and batteries, and repaired damaged insulation. After five upgrades, Hubble no longer carries any of the scientific instruments it had at its 1990 launch.

Despite the unqualified successes, the final servicing mission almost didn’t happen. After space shuttle Columbia and its crew were lost in 2003, NASA cancelled all flights to destinations other than the International Space Station, for fear that if the vehicle were damaged, the crew would be unable to return to Earth. With astronauts barred from visiting Hubble, Cepollina pushed for a daring alternative: He would send a robot to repair the telescope, using procedures and tools honed by more than a decade of planning astronaut repair missions.

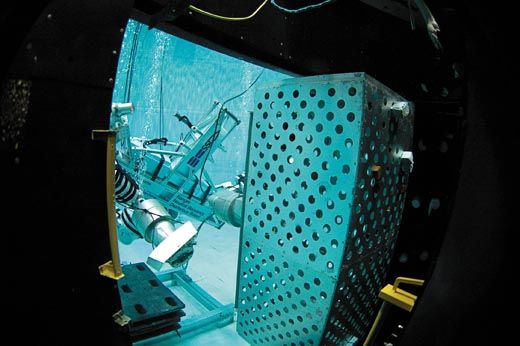

In the interest of time, the Goddard team chose an existing robot for the job: the Canadian Special Purpose Dexterous Manipulator, which was already built and waiting to be launched to the space station (where it’s now known as Dextre). Starting in 2004, Cepollina’s team worked feverishly in Maryland and in Canada to prove that Dextre, using tools attached to the end of its robot arm, could accomplish tasks normally done by astronauts: replacing two large science instruments, a fine-guidance sensor, gyroscopes, and batteries. The work involved lots of unbolting and bolting, as well as numerous electrical and data connections. In practice sessions using high-fidelity Hubble mockups, Dextre showed that it could handle the work. The team even simulated the two-second time delay that skeptics thought would be a severe handicap when the robot was tele-operated from the ground. Not a problem.

Once again Cepollina worked the PR channels, appealing directly to Congress and the media, pushing a robotic mission. This time, though, the answer was no. NASA asked the National Academy of Sciences to review its plans for Hubble servicing, and the verdict, rendered in December 2004, was that a robot-only mission would push technology too far, too fast. It wasn’t impossible, said the academy, but there were too many unknowns—including whether an automated spacecraft could rendezvous and dock safely with Hubble—to pull off a complex robot mission with just three years of planning. NASA went with astronauts instead.

“I do think they [the academy] were unduly conservative,” says David Akin, a space roboticist at the University of Maryland who helped Cepollina’s team with underwater testing of their procedures. But Cepollina accepted the finding and turned immediately to planning the astronaut repair, while keeping the robot option on the back burner. The tools and procedures developed for the robot mission made the astronaut service call far more efficient, he says. “It allowed [the astronaut crews] to do seven or eight days of work in five.” And during the last servicing flight his team was able to conduct experiments, in parallel with the astronaut repairs, to evaluate capabilities such as robot vision. “We never stopped moving [to develop robotic servicing].”

Now, he says, “I’m proposing to take the next step.” Congress has given him $70 million—a large amount in the field of space robotics—for a space station experiment to demonstrate robotic satellite refueling. Ground tests are under way at Goddard, and by the end of this year Cepollina plans to use Dextre to demonstrate all the steps of refueling on a hardware mockup equipped with standard satellite ground refueling valves, connections, and insulation blankets. The test goes by the name R2D2, for Robotic Re-Fueling Dexterous Demonstration.

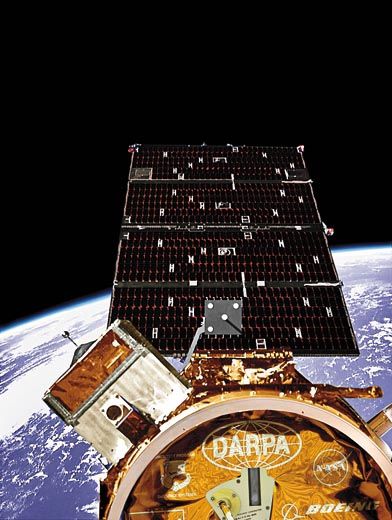

Cepollina concedes that at the time of the academy study, certain critical steps in robot servicing had not been demonstrated in space. But many of them have been since. The Defense Department/NASA Orbital Express mission, flown in 2007, showed that one satellite could dock with another automatically, use a robot arm to change the second satellite’s modular components, and transfer fuel. A low-cost Air Force satellite called XSS-11 was able to maneuver precisely around other spacecraft, and Dextre was installed on the space station in 2008.

“Orbital Express did all the things the academy said would be too difficult and risky,” says Cepollina. As a result of these projects, space robotics has convinced some former skeptics. “The technology has not advanced that much [since the academy study],” says Akin. “But the perception of it has changed tremendously.”

If the space station test goes well, Cepollina hopes to work out a deal to refuel several NASA and military satellites that are still in perfect working order except for lack of fuel. He envisions those missions jump-starting a commercial business to refuel and extend the lives of communications satellites that produce billions of dollars in revenue. “Once [refueling is demonstrated], the whole system could be turned over to commercial contractors,” says Cepollina.

Akin agrees, although he thinks that to be affordable, an operational system would probably have to use a smaller, lighter robot than Dextre. And, he says, “I give Cepi full props” for taking the lead in proving the feasibility of robotic servicing.

Cepollina seems worried only by the prospect of competition. A Swedish company, Orbital Satellite Services, is developing a spacecraft tug, based on the European SMART-1 moon probe, to extend the lives of commercial communications satellites by serving as a new propulsion system. It’s a simpler and likely cheaper alternative to refueling, with no capability (at least initially) to handle more complicated repairs. Dennis Wingo, a principal in Orbital Satellite Services who has been working on plans for commercial satellite servicing for years, says the company already has one “hard, signed contract,” although it has yet to nail down the financing it needs for a refueling mission.

But Cepollina has decades of experience, a dedicated team, and now, approval and funding for a test on the space station. If this turns into a race, you might not want to bet against him.

Robert Zimmerman’s latest book is The Universe in a Mirror: The Saga of the Hubble Space Telescope and the Visionaries Who Built It (Princeton, 2008).