Orbiter Autopsies

What NASA will learn from dissecting Atlantis, Discovery, and Endeavour

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Orbiter_Autopsies_4_FLASH.jpg)

Technicians had worn them for decades as they prepared the space shuttles for their move from Kennedy Space Center’s three Orbiter Processing Facilities to the towering Vehicle Assembly Building, and eventually the launch pad. “Bunnysuits,” those white coveralls with floppy hoods and rubber-banded booties, were designed to keep dirt and debris from contaminating the orbiter interiors.

But on this summer day in one Orbiter Processing Facility, technicians working inside Discovery’s crew module wore street clothes. No need to worry about contamination: Discovery would not be returning to space.

After flying 148 million miles and orbiting Earth 5,830 times, Discovery, first flown in August 1984, was being decommissioned and readied for its trip to the National Air and Space Museum’s Steven F. Udvar-Hazy Center in northern Virginia, where it will arrive in mid-April. The three main engines had been removed from the shuttle’s aft end, which was now covered by a tightly fitted mask with three white discs the size of the engine bells. Clear plastic stretched across the crater in the orbiter’s nose, where the forward reaction control system—small thrusters that maneuvered the spacecraft in orbit—had been removed. And this harvesting of the orbiter’s components was only the beginning.

In late autumn of last year, more than six months after Discovery landed for the final time, NASA crews began peeling back the orbiter’s skin, clipping wires, and pulling hydraulics. They removed and analyzed propellant tanks and valves and scrutinized electronics, looking for evidence of deterioration the way coroners look for signs of illness during autopsies.

“ ‘Autopsy’ is a sad way of putting it—these vehicles are almost like our friends—but it’s what we are doing,” says Joyce M. Seriale-Grush, orbiter chief engineer at NASA’s Johnson Space Center in Houston, Texas. “We have been evaluating this hardware with nondestructive tests throughout their history. Now we can actually tear some of this hardware down.”

The orbiter autopsies can determine whether the best estimates and educated guesses NASA engineers relied on to keep the shuttle flying for three decades were trustworthy. The results could improve the understanding of shuttle failures and guide the design of future spacecraft.

Before the autopsies could begin, however, workers in the Orbiter Processing Facility had to “safe” each vehicle, removing toxic propellants and hydraulic fluids as they had done hundreds of times before. Crews, shrunk by layoffs, attended first to Discovery, then Endeavour, and finally Atlantis.

“You think you want to do something that you normally would do, and they say it’s not required for where this shuttle is going,” says Terry White, project lead for the orbiter thermal protection system and a 32-year shuttle program veteran. Some habits die hard. On the aft end of Endeavour, the ports for purging nitrogen from the reaction control thrusters on the orbital maneuvering system pod are covered with cloth sporting a notice reminding workers to “remove before flight.”

Orbiter Processing Facility 2 is all about warnings. The blue metal door leading inside bears two against unauthorized entry, a third about electrical hazards, and a caution against unfastened objects.

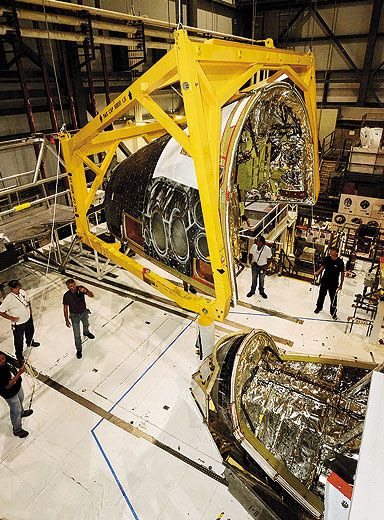

Once inside today, the orbiter processing team will remove one of Endeavour’s two orbital maneuvering system pods, which bookend the vertical stabilizer. As the drone of ventilators fills the building, a technician wearing a “Lucky’s Bar” T-shirt thumbs a manual detailing the steps for excising the orbital maneuvering systems. Held by a latticework of steel beams, the pod rotates out and into the free-hang position, ready for the next day’s crew to winch it into retirement.

Long gone are Endeavour’s main engines. Technicians have plucked them with what looks like a Space Age version of a medieval battering ram. Mounted on a 20-foot-high forklift, the steel probe, its tip sheathed in black padding, had pressed into the nozzle of each engine. It extracted them one at a time, hauling them away for storage in a NASA facility at White Sands, New Mexico. If Endeavour’s engines fly again, it will be on NASA’s new Space Launch System, a Saturn V lookalike now in the planning stages.

The shuttle’s emergency crew escape system featured an extending pole; these will be collected from all three orbiters. “That’s a safety reason” for the collection, says Stephanie Stilson, orbiter transition and retirement flow director. “You have some energy built up in that system, where you could potentially hurt someone” if the pole were left intact.

The airlocks and docking rings through which crews on Endeavour and Atlantis entered the International Space Station will be gathered and stored for possible later use. (Discovery’s airlock and docking ring will remain in place.) And technicians have pulled the robotic arms from all three orbiters. Atlantis’ arm will remain with NASA, while Endeavour’s will be returned to the Canadian Space Agency, which developed the technology. Discovery’s robotic arm will go on exhibit at the Steven F. Udvar-Hazy Center.

Discovery returned from its last mission in March 2011, and just weeks later, crews took out the forward reaction control system. The forensic rhinoplasty began with members of the orbiter processing team fanning out across Discovery’s nose while a winch operator levitated the control system slowly up and away from the shuttle. The thruster assembly, bolted into a steel-beam frame, was placed on a trailer, where technicians scrubbed the forward reaction control system of its toxic fuels and oxidizers before reinserting it into the orbiter. In the aft end of the spacecraft, the holes once filled by Discovery’s main engines will be filled with replica engines built from test components. Any additional cavities created by the removal of orbiter components will be covered by panels to make their absence impossible to detect from the outside.

Four months after NASA ferries Discovery atop a modified Boeing 747 to Dulles International Airport (near the Udvar-Hazy Center), Endeavour is scheduled to move to the California Science Center in Los Angeles. And in February 2013, Atlantis will be rolling toward the visitor’s center at Kennedy Space Center in Florida.

The main reason for examining orbiter pieces left behind—wires, feed lines, tanks, valves, and electronics—is to avoid future failures, says John Shannon, NASA shuttle program manager. NASA engineers already have some ideas about what to look for. During the ascent of Columbia on mission STS-93 in July 1999, an electrical short knocked out the computer-based controllers for two of the three main engines. When the engines switched automatically to backup controllers, the mission was saved. It was later determined that mishandling of a wire damaged its insulation. Vibration during repeated launches had caused further wear until an exposed conductor touched a screw, the contact shorting the controllers five seconds after liftoff.

NASA tried to remedy the problem by giving wires a protective covering, an arduous process that may not have had the desired effect. “So we want to go back and look at the wiring to see if there’s anything to be learned,” says Francisco J. Hernandez, deputy chief engineer for orbiter propulsion and power subsystems. “The wiring methods and design are very similar to what is done in the aircraft world, so this is something that is not only potentially applicable to future space vehicles but also maybe to the aviation community.”

In addition, engineers will examine shuttle avionics for signs of “tin whiskers,” wispy extrusions of tin molecules in circuit-board soldering that expand in zero gravity. Knowing the extent of their growth over time could help operators of satellites that use the same tin soldering predict when the satellites could fail. “Long whiskers are a great way to short out a circuit,” says Shannon. “We had a satellite short out, and we think tin whiskers was the most likely cause.”

Orbiter autopsies may also benefit the space station: Cooling systems there use a highly corrosive type of ammonia that was also used on the shuttle. So engineers are examining orbiter cooling systems for signs of damage. “These kinds of failures sneak up on you, and they are not necessarily easy to find,” says Thomas M. Simon, commercial crew assistant chief engineer. “So even if we find [only] a couple issues, the relative cost of these studies compared with losing a mission or setting up an entire test program is a big savings to the agency.”

Analyzing orbiter elevons could yield dividends as well. Each orbiter has four of these control surfaces, two on the trailing edge of each wing. Elevons roll the spacecraft left and right, and pitch the nose up and down. During a pre-launch test for STS-101, which launched on May 19, 2000, the actuators that controlled Atlantis’ elevons failed. NASA followed up by testing every actuator on every orbiter and discovered that in some cases hydraulic fluid had accumulated in tight spaces instead of flowing freely. The problem was traced to microscopic silt, contaminants in the hydraulic system that impede flow like plaque slows blood in the body.

NASA prescribed regular exercise: moving the actuator at varying speeds to force the fluid to circulate better and dislodge the silt. Hooking external filters to the hydraulics removed the silt from the lines. The desilting restored full motion to the actuators, but NASA engineers worried that the devices might have experienced other types of degradation.

Over the last 10 years, every shuttle elevon actuator except two had been refurbished, so NASA could not analyze them for the effects of long-term use. Atlantis has its original actuators; Hernandez expects to get his hands on at least one. “There are types of degradation that don’t get to the point where they affect top-level functionality,” says Hernandez. “The idea is to understand this degradation and to build techniques to catch and prevent degraded hardware before it manifests at a top level of functionality.” Knowing how space shuttle actuators degrade could, again, mean a lot to the aviation industry, which employs similar hardware in commercial and military aircraft. By publishing articles in scholarly journals and agency technical publications, NASA engineers will share knowledge gained from the orbiter autopsies.

In addition to their degraded actuators, the orbiters have aging plumbing lines leading into the main engines that could prove troublesome. Years ago, routine inspections revealed cracks in the flow liners of the feed lines, which carry liquid hydrogen from the external tank to the shuttle main engines. “If they had broken off, they could have gone into the engine and caused a catastrophic failure,” says Seriale-Grush.

NASA replaced the flow liners, but had no way of knowing if there were cracks higher up. While the orbiters were still flying, removing the 12-inch-diameter feed lines would have cost millions of dollars, an unjustifiable expense considering there was no evidence of damage. It would be like removing a person’s colon to see if there was cancer, just because the patient was getting old.

Borrowing a page from modern medicine, NASA decided to go another way. Technicians threaded borescopes into the shuttles’ plumbing to look for cracks. Technicians performed these fuel-line colonoscopies regularly, searching for the tiniest signs of damage. The examinations kept the shuttles flying, held costs down, and minimized risk. Studying the feed lines now will show just how much risk remained.

Whenever possible, NASA used nondestructive testing. For example, engineers used thermography—the imaging of infrared radiation—to scan orbiters during landing to evaluate heat distribution across the reinforced carbon-carbon wing leading edges. Nondestructive testing has a role even now that the shuttles have been retired. During its stay in the Vehicle Assembly Building, Discovery was scanned with a laser technique known as photogrammetry, which plotted each surface point on the underside of the spacecraft, digitally capturing the slight asymmetries that had crept into its manufacture some 30 years ago. With this information, engineers can develop a computer simulation of Discovery in hypersonic flight. Data generated by the simulation will then be compared with data from the orbiter’s actual hypersonic flight. “We want to see whether our prediction tools can reproduce what the flight data tell us,” says Charles H. Campbell, a NASA deputy principal investigator. “That’s never been done before with the orbiter.”

Campbell and his team are especially interested in modeling the thermal changes that occur when the air surrounding a vehicle flying hypersonically changes from smooth to turbulent in a process known as boundary layer transition. “We can’t test this on the ground,” says Campbell. “You have to be in flight.”

The boundary layer transition might, however, be computer modeled, using the hypersonic data acquired during Discovery’s flights and the optical mapping data obtained from the photogrammetry. Computer simulations based on this information would not take the place of the real thing, but they could help predict the behavior of future hypersonic vehicles and aid in the development of next-generation spacecraft.

The digital mapping will also afford NASA engineers the opportunity to aid in expanding the Discovery museum exhibit with computer models. And the engineers are doing everything possible to make the orbiter look just like it did when it landed. All signs of Discovery’s surgeries will be hidden and its empty spaces filled by replacement parts, which might not fit exactly—at first.

“We’ll push a little here and push a little there,” says Mike Parrish, vehicle operations chief. “We’ll work through it, and make sure it gets done right.” If all goes well, Discovery will be as successful an artifact as it was a research vehicle during nearly 30 years of flight.

Freelance writer Greg Freiherr specializes in medical and aerospace technologies.