Printed in Space

If your star tracker breaks on the way to the moon, just hit Command P.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Printed-in-Space-lunar-tasks-7-flash-631.jpg)

At a recent conference on the future of aerospace, 27-year-old entrepreneur Jason Dunn outlined his philosophy of why, after more than 50 years of space exploration, humans are not yet living in space colonies. “Everything manmade that’s ever been in space had to be built and launched from the ground,” he says. “And that puts enormous constraints on what you can actually do in space, because everything has to survive launch. So how do you get around that?”

His suggestion: Don’t manufacture things on the ground.

Dunn’s Silicon Valley startup company, Made In Space Inc., would reinvent the space industry by putting into orbit a cheap, easy mode of manufacturing: the 3D printer. It doesn’t print in the normal sense. But like an ordinary desktop printer, it receives instructions from a computer (in this case a computer-aided design, or CAD, file). Instead of arranging patterns of ink on a 2D sheet of paper, the 3D printer builds a solid object. Whereas traditional manufacturing techniques start with a solid block and cut unwanted material away from it, 3D printing—also called additive manufacturing—builds up material in layers, producing precisely the object desired with almost no waste.

3D printing is a growing industry on Earth, and has the potential to change not just the cost and speed of manufacturing but also the design of everything from airplanes to buildings. It could, in theory, have an even bigger impact on the space industry. For example, a Mars robot probe “printed” from a CAD file in orbit could be made 30 percent lighter than one that has to withstand the stress of a rocket launch from Earth. Human interplanetary missions that don’t have to bring along spare parts—because they can be made en route—will have more room for necessities like food, water, and oxygen. Not only could 3D printing make human space exploration easier, it could make certain kinds of exploration possible.

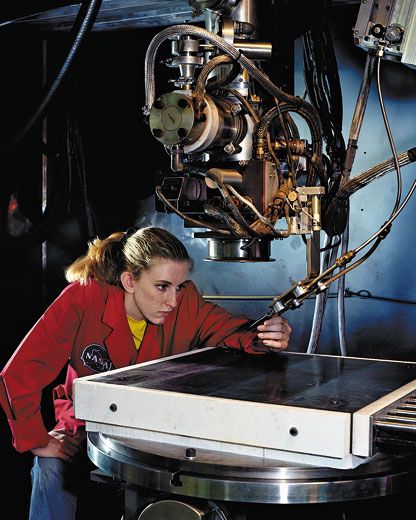

Today, only a handful of people are working to adapt this technology for space, and their approaches vary. Made In Space’s prototype machines print simple plastic items by extruding a polymer-based material through a nozzle. Other methods of 3D printing use different feedstocks: powder, metal, even glass. Karen Taminger of NASA’s Langley Research Center in Virginia is working with a metal-printing technique called Electron Beam Freeform Fabrication, which she hopes to test on the International Space Station. The EBF3 method, as it’s called, uses a beam of electrons to melt metal wire, like a cross between a laser gun and a soldering iron, and deposits the metal in layers. The technology is ideally suited to space because electron beams require a vacuum, and, as Taminger explains, “in space, you’ve got vacuum for free.”

The current lab version of EBF3, bought from a commercial welding supplier in 2002, sits in the middle of a giant warehouse called the Fabrication Shop at Langley. The shop is filled with machines, including a cluster of 3D printers all quietly chirping away, making objects out of gel, wire, or plastic. The EBF3 device is one of the more imposing pieces. It’s a greenish-blue cube nine feet on a side, with a heavy sliding door and round windows like a space capsule’s. That’s only the vacuum chamber part. Inside, the electron gun and accompanying wire feeder hover over a heavy metal platform where relatively small metal objects (a maximum of six by two by two feet) are fabricated.

The whole apparatus weighs 50 tons. That’s far too heavy, obviously, to launch into orbit. “This system isn’t going anywhere,” says Taminger. But she and her team have built a smaller version that weighs only a ton, and are working on another that’s less than 100 pounds. At first, they’ll have to build a small vacuum chamber to house the printer inside the space station, where astronauts can easily use and maintain it, but in theory an operational version could be mounted on a platform outside, where there’s plenty of vacuum. If the part needs finishing, the astronauts could do that inside, using a glovebox to keep any excess material from floating around the station.

The most useful application of 3D printing in space may be the production of spare parts and tools. If something on the station breaks or gets lost, the crew often has to wait weeks for the next supply ship to bring up a replacement. Because a 3D printer requires only a bit of feedstock and a CAD file, it will be possible to print what the astronauts need as they need it.

The EBF3 technique could even be used for repairs. “One of the alloys we’re working with is 2219, which is the aluminum alloy that the entire [station] is built out of,” says Taminger. “Our goal is to have a small enough system, almost a hand-held type system, so the astronauts could go out and say ‘I need a fix there’ and be able to actually do a repair [on a spacewalk].” To see if the technique could help repair damage from a cosmic hailstorm, Taminger’s team plans to try using EBF3 in their lab to repair aluminum panels shot through with simulated micro-meteorites.

Making parts in space would dramatically reduce the mass sent to the station. Taminger points to a recent Johnson Space Center computer simulation that predicts ISS equipment failures. In any given simulation, five percent of the parts needed replacement. But it was never the same five percent. You could try to predict a replacement part you might need, but chances are you’d end up needing something else. Taminger thinks logistics planners could take advantage of these odds by sending up a 3D printer and enough feedstock (stored, perhaps, in an attached module) for just five percent of the station’s total mass of spare parts. The astronauts would be given CAD files for all the parts that might break, and would print out only what they needed.

That strategy could be important, even essential, on a human Mars mission, where no supply ships would be coming, so the astronauts would have to pack everything with them. Taminger has done some calculations based on NASA’s current Mars mission architecture. A Mars-bound ship would include roughly 20 metric tons of machined parts. To carry one spare for every part would add 20 tons. But if only 10 percent of the parts are likely to fail, and any one of them could be printed from a CAD file in flight, the ship would need to carry only two tons of feedstock. Printers should also, in principle, be able to reconstitute old tools and parts for use in making new ones.

Other kinds of space fixes might require a totally new part—maybe something no one has built before. 3D printing enables astronauts (or ground controllers) to design and fabricate it on the spot. By way of example, Jason Dunn of Made In Space evokes the near-catastrophic Apollo 13 moon flight, during which the crew and mission control had to jury-rig an essential air filtering mechanism using plastic moon rock bags, cardboard, spacesuit hoses, and duct tape. “If they’d had a 3D printer,” says Dunn, “they could have easily just 3D-printed that exact part that they needed.” To prove it, Made In Space spent about 20 minutes designing a part that would have fixed the Apollo 13 problem, then printed it the same day.

Astronauts don’t often need such makeshift tools, but it happens. In 2007, when one of the space station’s giant solar arrays got torn, the crew crafted six “cuff links” out of wire, strips of aluminum, and Ziploc bags, and used them to close the tear. As on Apollo 13, mission control had to figure it out on the ground first, then send up detailed instructions. Oh, to have had a 3D printer.

With astronaut time a scarce commodity in orbit, technology designed for the space station should be easy to use, and as automated as possible. Taminger says the involvement of companies like Made In Space (which counts software maker Autodesk as one of its sponsors) will bring much-needed user-friendliness to the space-based 3D printing industry. “The advantage that commercial entities have is that they’ve worked with a lot of external customers,” she says. “They’ve seen a lot of different geometries, different parts being built.” She acknowledges that NASA-built printers, which are run by the engineers who designed them, aren’t great in the user-friendliness department.

But while Dunn and Made In Space are looking far ahead to space colonies humming with 3D printers, Taminger is busy putting one foot in front of the other. Over the past 10 years, she and her team have been carefully incorporating NASA’s safety and quality standards into their EBF3 process, aiming to prove the system’s reliability before getting a chance to fly on the space station. They’ve tested their process during short periods of zero-G on airplane flights (it works), but there are many other factors to consider when bringing a manufacturing process into the closed environment of the space station. Waste products have to be contained—some materials can emit dangerous chemicals—and anything printed in orbit has to be reliable enough to be picked up and used immediately without extensive testing.

“If this is actually going to be a technology that the astronauts are going to depend on for their lives, you have to have a known quality,” says Taminger. Her task now is to convince NASA that such gear will be trustworthy.

Last year she got a break when an ammonia pump in the space station’s cooling system failed, and had to be returned on the space shuttle. The pump had to be mounted inside the shuttle’s cargo bay, and NASA engineers designed a new tool to help spacewalking astronauts secure it. Taminger used EBF3 to print part of the tool and put it through the same safety and effectiveness tests that all parts have to go through before they’re cleared for spaceflight. Her part didn’t actually fly on the shuttle (a conventionally produced tool did), but going through the tests showed NASA that 3D-printed parts can be just as good as their traditionally manufactured counterparts.

Other teams—including at least one overseas—also are working out the details of how to space-qualify printed parts. Giorgio Musso at Thales Alenia Space, an Italian company that built several of the space station’s modules and often contracts with NASA, recently completed an extensive study of 3D printing for the European Space Agency. Musso and his colleagues found that, depending on the technique used, some parts made with a printer were actually stronger than traditionally made parts, while others still needed improvement before they could have been used in space. Musso would like a chance to test 3D printers on the space station someday, but in the meantime he’s focused on the problem of printing space-qualified parts faster and more cheaply on the ground.

Made In Space, a newcomer to the aerospace world, is looking for private investment in addition to the modest amount of technology development funds it receives from NASA. The company is nothing if not ambitious. “We would love to be the people who build everything in space,” says Chief Creative Officer Alison Lewis. She laughs, but she’s not kidding. “Our long-term goal is to be the manufacturers of all structures and spacecraft in space.” Like Dunn, Lewis is a graduate of Singularity University, the future-minded educational institution based in Silicon Valley.

University of Southern California engineer Behrokh Khoshnevis is a visionary of another sort. With funding from NASA’s Innovative Advanced Concepts program, his research team is developing a large-scale additive manufacturing system, called Contour Crafting, for building structures on the moon. They would use lunar regolith—moon dust—as feedstock, possibly mixed with melted sulfur, an element also available on the moon. With liquid sulfur, no building materials would have to be transported from Earth. (If water were needed as the binder, hydrogen might have to be imported to mix with oxygen that was extracted from lunar soil.)

Khoshnevis envisions mounting a giant 3D printer atop large rovers to fabricate lunar shelters layer by layer, and that’s just the beginning. “We have to have robotic systems that can [not only] build structures, they should be able to build other objects,” he says. “They should be able to build other robots.” Contour Crafting, he believes, could be used to construct an entire lunar town—landing platforms, hangars, habitat, manufacturing facilities, all made out of local materials.

“It’s not a trivial project,” says Khoshnevis. “But we love projects that are not trivial.”

Right now, the move toward in-space manufacturing is bottlenecked at the main place where new technology gets tested in orbit—the space station.

Like Taminger’s team, Made In Space has tested its printers on zero-G airplane flights, and the company is planning a suborbital sounding rocket mission that will provide a few minutes of weightlessness in which to test, instead of the usual 30 seconds at a time that airplanes provide. But these flights are small potatoes compared with sustained experimentation on the space station, and the queue for researchers to get lab time is long.

Made In Space doesn’t expect to get a test printer on the ISS manifest before 2014, and even then it would be just that: a test printer. Taminger hopes to fly a fully functional printer that the astronauts could rely on for spare parts and tools—that is, if NASA comes through with technology development money, which is always in short supply. “We’ll be ready to go [to the station] within two years of getting the funding,” she says.

Musso says the money situation is no better in Europe: “The space community is much more interested in other technology that will help the survivability of [crew members], the regenerative technologies for water and air. In the scale of priorities, additive manufacturing is not at the top.”

He says that when NASA first began its race to the moon, engineers were given carte blanche and all the money they needed to come up with whatever crazy idea might make it happen. Taminger agrees that NASA has gotten more conservative, and the agency may not be willing to take a risk on a new technology, even one that could potentially transform space exploration.

That conservatism has pushed Made In Space to search for private backers as a way to speed things up. Meanwhile, the company, which is based at NASA Ames Research Park at Moffett Field, California, gets by on small NASA grants.

As Dunn and his team flew repeated parabolic arcs in a modified Boeing 727 on a recent flight, experiencing weightlessness for under a minute at a time, they managed to print several items, including their first tool—a wrench.

“The wrench was built in eight minutes,” he says. “It’s a very small wrench.” While the airplane was falling through the sky, the team even torqued a bolt to demonstrate that their creation could be used in space.

“Yeah, so we built a tool,” says Dunn with a kind of wonderment. One small step for man.

Mark Betancourt is a writer and filmmaker living in Washington, D.C. He wrote about space-diver Felix Baumgartner in the June/July 2012 issue.