Robo Repairmen

It’s getting harder to find good help these days. So these space engineers built their own

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/repair-388-jul05.jpg)

ON A SWELTERING SUMMER AFTERNOON, Dave Akin, an associate professor of aerospace engineering at the University of Maryland, heaves open a thick steel door and directs me to a stairwell inside a red brick monolith called the Neutral Buoyancy Research Facility, part of the school’s Space Systems Laboratory in College Park. The building houses a 367,000-gallon cylindrical fiberglass tank of sparkling blue water used to conduct experiments under weightless conditions, or as close as we can get to weightlessness here on terra firma.

Akin is clad in sandals, cargo shorts, and a souvenir T-shirt from NASA’s nearby Goddard Space Flight Center that’s stained with barbecue sauce from a school picnic he attended at lunch. Plump, bald, and bespectacled, he greets me with a husky handshake and a warm smile, then bounces up five flights of stairs to the top-floor control room, where a team of grad students is about to lower the Ranger space robot into the water.

Autographed astronaut posters adorn the walls of the room; junk food is strewn across a long conference table. Near the door is a dinged-up computer that’s missing its front panel. This is Ranger’s main processor. A thick gray cable snakes from the box through a hole in the wall and into the water tank, where it’s plugged into a data port on Ranger. “That’s his brains,” says research engineer Stephen Roderick when he catches me tapping on the box with my pen.

Minutes later Akin is outfitted in scuba gear and hovering 25 feet down near the bottom of the tank as Ranger slowly swings its arms to and fro, pivots at the waist, rotates its wrists, and, like an irate lobster, clenches and opens its steel pincers.

Akin began building underwater robots like Ranger in the 1980s as part of a NASA-funded effort to learn how robots could help astronauts do their work in orbit, including servicing the Hubble Space Telescope.

So far, Ranger has struggled with its mission du jour: inserting a model of the Hubble’s Wide Field Camera into a drawer-like slot that matches the one on the actual telescope. Akin is busy snapping pictures with a digital camera and hardly notices when his 2,000-pound robot suddenly jerks backward after one of its joints gets jammed.

Roderick, who everyone calls “Kiwi” because he’s from New Zealand, operates Ranger via joystick and keyboard commands while watching its movements over TV monitors linked to five underwater video cameras. At least twice during the three-hour experiment, Ranger contorts itself into yoga-like positions that confound Roderick. Bubbles trickle from its housing, indicating leaks. And during the transition between certain movements, Ranger twitches unpredictably. But when Akin surfaces, he’s beaming. “That went really well,” he says, “considering that was the first time Ranger tried those moves.”

This all happened last summer, at a time when official government interest in space robotics had reached a historic high. Six months earlier, NASA Administrator Sean O’Keefe announced he was canceling a long-planned shuttle mission to replace Hubble’s aging batteries and gyroscopes and install an advanced camera and spectrograph. Worried about astronaut safety following the Columbia tragedy, O’Keefe wasn’t willing to risk lives to upgrade the telescope for the fifth time, no matter how much astronomers or the general public wanted it.

So the call went out to industry: NASA wanted to know if a robotic spacecraft could be built to carry out the servicing mission sans humans before 2008, the year in which the telescope’s batteries and gyroscopes are expected to fail. Akin, whose Ranger had been practicing some of those very tasks for years, answered NASA’s call. So did robotics experts from labs elsewhere in the United States, in Canada, and around the world.

MDRobotics in Brampton, Ontario, submitted one of the most promising proposals. The company had finished construction of Dextre (the nickname for “special-purpose dexterous manipulator”), a remotely operated two-armed robot already ordered to help astronauts service and maintain the International Space Station (ISS). NASA project managers knew that to launch a repair robot by the 2008 deadline, there was no time for research and development. So the agency asked MDRobotics to begin production of a second Dextre that could be launched on an unmanned rocket, then deployed in orbit to complete the tasks originally intended for the shuttle astronauts. Dextre would replace the Hubble’s batteries and gyroscopes, install the spectrograph and camera, and attach a rocket-equipped module that could deorbit Hubble and safely steer it into the ocean at the end of its life.

By last August, engineers at MDRobotics had completed much of the testing on Dextre that NASA required. But the space agency wasn’t ready to give them the green light until it heard from a National Research Council (NRC) panel it had commissioned to evaluate the risks and costs of a servicing mission to Hubble.

The panel’s final report, released last December, more or less concluded that it was impossible for robotic technology to be developed in time to save the Hubble. The committee, which included robotics experts, Nobel-Prize-winning astronomers, and veteran astronauts, relied in part on an exhaustive evaluation done by the Aerospace Corporation, a federally funded R&D think tank based in El Segundo, California. That study concluded it would take five and a half years to ready a robotic mission—nearly double what it would take to prepare a shuttle mission, and longer than the telescope’s predicted remaining lifetime.

As a result, NASA killed the Hubble robotic servicing option outright—and, for that matter, a shuttle servicing mission as well. The decision to scrap the telescope angered astronomers, and was a blow to ambitious roboticists like Akin, who’d hoped to prove their stuff by rescuing one of NASA’s most prized possessions. But Akin and others are philosophical, and say that not getting a crack at servicing Hubble is only a short-term setback. They believe that as we extend our reach farther into the Solar System, robots undoubtedly will handle many repair and servicing tasks, help assemble spacecraft in orbit, and even build outposts on the moon and Mars. “We see [robotic] capability being required for future space missions anywhere,” says Dan King, director of robotics at MDRobotics.

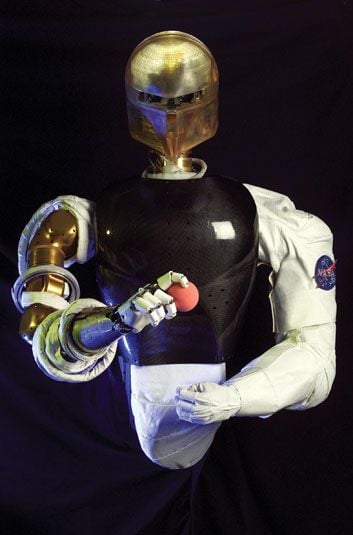

In fact, some of the teams that proposed robots to fix Hubble are already pursuing technologies far more sophisticated than those imagined for the Hubble mission. At the Johnson Space Center in Houston, for example, engineers recently added a seven-jointed leg to their humanoid space robot Robonaut. With its new appendage, Robonaut can simulate climbing in zero G. It features a built-in CPU, five-fingered hands, and more than 150 sensors. Project engineers claim that it has dexterity comparable to that of a gloved astronaut and better range of motion. “Robonaut could light birthday candles on my kid’s cake,” quips former project manager Rob Ambrose.

“Humans in space will want to have excellent tools, and some of these will surely be robotic,” says Rud Moe, who manages the Hubble servicing missions at Goddard. “In other cases, the robots will serve very well where humans don’t dare to go—or can’t go.”

After outfitting ourselves in lab smocks, donning white shower caps, and inexplicably jumping up and down on a blue floor mat (I later learn it’s to discharge static), Paul Cooper, vice president of business development and R&D for MDRobotics, takes me inside the company’s 18,000-square-foot clean room. Three enormous Canadian flags hang from the rafters. “Don’t touch anything,” says Cooper, reminding me that even the slightest bit of static could short out one of the many electronic components carefully positioned on lab benches around the room.

The 3,600-pound Dextre robot is toward the back, where it’s suspended from a block-and-tackle rig that allows engineers to evaluate its performance in simulated zero gravity. “Repairing Hubble is such a noble mission, crossing the boundary of science and reaching into the public interest,” gushes Cooper, who stubbornly maintains that a robotic servicing mission would have been a viable option. “It’s not just some pie-in-the-sky design idea. Dextre really exists. And it has already been built and tested for the ISS.”

In Congressional hearings last Frebruary, members of the House Committee on Science questioned Cooper about the risks outlined in the NRC report—things like the time lag in robotically executing commands from Earth, and the feasibility of latching onto Hubble, which lacks a docking interface. Cooper pointed out that before a Hubble servicing flight would take place, other space missions would solve these technical challenges. Two such missions were launched this spring—NASA’s Demonstration of Autonomous Rendezvous Technology (DART) and the Air Force-sponsored XSS-11. Both were designed to prove that one spacecraft could meet up with another in orbit and work in close proximity, safely, with no human supervision.

“By the time we launch [Dextre],” Cooper argued in his testimony, “there’s going to be nothing left for us to do but actually go up there and do the mission, because everything we could possibly think of will have been covered by that point.” But DART had only mixed success, getting close to its target but then actually bumping into it.

Last summer, when robot rescue was still a possibility, astronauts and technicians at Goddard practiced maneuvers with Dextre on a life-size replica of the Hubble. The tests even simulated a two-second delay in Dextre’s response to human commands radioed from Earth. Cooper plays me a video from the Goddard shakedown that shows Dextre opening and closing panel doors on the Hubble mockup, twisting bolts, and yanking out power cords. Before Dextre can begin each task, it must switch the tool affixed to its “end-effector.” The device is similar to a dentist’s multi-tool driver: Dextre can swap out the heads—one for turning a screw, another for clamping onto a cable, a third for rotating a knob or opening a latch.

On the video, the tasks seem simple enough. And Cooper reminds me that once Dextre is joined with Hubble in orbit, there will be no rush to finish the job: “One of the nice things about a robotic servicing mission is it doesn’t matter how long it takes. There are no astronauts to be fed, no shuttle landing schedule. Dextre could take days and weeks if it wants, trying different things over and over again—all of which enhances its probability of success.”

Of course, here inside NASA’s lab, Dextre and the Hubble replica are in a controlled setting. Nobody knows exactly what would happen if they’d been drifting side by side at 17,500 mph, hundreds of miles from Earth. The NRC panel worried that the robot could easily be thrown by unexpected glitches, like connecting pins that turned out to be bent instead of straight.

Kathy Thornton, a former shuttle astronaut, performed the first repairs on Hubble during a 1993 mission. She points out that most of the panels, latches, doors, and connectors on the telescope were designed for humans. “All those interfaces that were made for people to use would be more difficult for robots,” says Thornton, who left NASA in 1996 to teach engineering at the University of Virginia in Charlottesville. “Some of the connectors would be very hard to change, and not many of the end effectors [on the robots] are made to capture things when they start floating around.” Thornton says that a robotic servicing mission would have been “a great engineering exercise” but that it could have been more likely to damage Hubble than an astronaut repair mission.

Even a relatively simple teleoperated docking can end in disaster, something I witness firsthand inside a rectangular lab at MDRobotics known as the Bowling Alley. Engineers George Bailak and Andrew Allen are trying to develop a remotely operated spacecraft that can dock with a variety of satellites. In the center of the lab are two granite platforms positioned side by side. The engineers have placed a 1,500-pound satellite replica on one and their 260-pound robotic coupler on the other. They both rest on circular pads called precision air bearings. When high-pressure nitrogen is pumped through the bearings, the spacecraft begin to float like pucks on an air hockey table (this is Canada, remember), gliding a few millimeters above the pads.

After a pre-programmed computer sequence initiates the docking procedure, short bursts of pressurized air begin to slowly propel the coupler toward the satellite. A barbed hook on the end of the coupler is supposed to snag the inner lip of the satellite’s thruster cone. The two craft barely touch when the satellite suddenly swings sideways. A second try produces a similar result. Only on the third attempt—with Bailak and Allen physically nudging each craft to maintain the proper alignment—does the docking succeed. Later, I try the same procedure on a simulator. After a promising start, I crash the docking craft into the virtual satellite, tearing off half its solar panels and sending it into a death spiral.

Bailak and Allen brush off my cosmic train wreck as a minor hiccup along the robotic servicing learning curve. Besides, they say, autonomous rendezvous and docking are precisely the problems that projects like DART and XSS-11 are meant to address. DART’s program manager, Jim Snoddy, calls his mission “a prototype of many things to come,” including the orbital assembly of spacecraft bound for the moon and Mars. “When we start putting more pieces in space, we’re going to have to start putting them together,” he says.

A major hurdle will be developing a robotic arm that can adjust its sensitivity as it pushes and pulls on connectors and cables. Ideally, a robot would react to physical resistance much as a person does—by turning a screw more slowly and carefully, for instance, if it felt the threads beginning to strip.

Gerd Hirzinger, director of the Institute of Robotics and Mechatronics, part of the German space agency, DLR, hopes to overcome this problem with a remotely operated mechanical arm called ROKVISS (Robotic Component Verification on ISS). ROKVISS is a double-jointed arm about two feet long, with a self-contained power supply and a finger-length stylus tool. A Russian resupply craft delivered ROKVISS to the space station in December. It was mounted to the outer wall of the Russian Zvezda module, where it could be operated from a ground station located about 15 miles from Hirzinger’s lab outside Munich.

In March, ROKVISS completed its first set of maneuvers, “proving that the concept of torque-controlled joints” is mature enough to work in space, says Hirzinger. The joints, he adds, are “similar to human muscles—you can them make stiff or soft.” The ROKVISS arm also incorporates a stereo camera. According to Hirzinger, once the robot makes contact with a contoured shape, the arm can either maintain an even pressure anywhere along the object, or apply “high-fidelity force feedback” to vary the pressure. Imagine hand-sanding an intricately carved wooden table leg: If you don’t adjust your pressure to accommodate the leg’s curves, the finish will become uneven, smoother where it’s convex but still rough along the concave surfaces. Hirzinger plans to continue testing ROKVISS aboard the station for a year. “If the joints turn out to work perfectly in space,” he says, “then we’ll immediately start building a seven-degrees-of-freedom free-flying robot.”

Eventually, the follow-on system would be used to demonstrate in-orbit satellite servicing.

Meanwhile, in Houston, Rob Ambrose’s group has built a mobile platform for Robonaut. Funded by NASA and the Pentagon’s Defense Advanced Research Projects Agency, Robonaut has simmered along since 1996 as a low-priority technology development effort. Despite its popularity with the press and its Hollywood good looks, the humanoid robot has never been called for an assignment in space.

Ambrose hopes NASA’s recent focus on building a lunar base could change things. Recently his team removed the robot’s single zero-G leg and mounted its torso to a mobile platform based on the Segway scooter. They wired Robonaut’s computer interface directly into the Segway’s control system, giving the robot control over its balance and motion. “We would like to put our robots in a precursor role: setting up a work site or habitat on the moon,” says Ambrose, who is now looking for a four- or six-wheel platform suitable for rough lunar terrain. “If I were going to be sent to the moon, I would want my habitat already making oxygen, already 72 degrees, holding air, and not leaking.”

Back at the University of Maryland, Ranger’s successors continue making dives in the neutral buoyancy tank, but now Akin is adapting them for more generic work. His team is also working with NASA’s Astrobiology Science and Technology Experiment Program to develop a Ranger-type robot that could collect planetary samples—perhaps on Jupitor’s moon Europa.

As for Hubble, the new NASA administrator, Michael Griffin, may reverse his predecessor’s decision on a shuttle rescue, but has come out against letting robots save the 15-year-old telescope. No matter—the machines’ day will almost certainly come. That’s another advantage robots have over humans: They’re endlessly patient.