Son of a Buzz Bomb

An engine with a checkered past is the power of the future.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/pulse_388-sept07.jpg)

In the summer of 2000, the world was about two years away from seeing the Next Big Thing in aircraft engines fly supersonically. NASA proudly declared that its Dryden Flight Research Center in California would lead the way, flight-testing on a modified F-15B research aircraft a scaled pulse detonation engine, or PDE, built by Boeing.

It was an audacious notion, but the space agency was confident. The pulse detonation engine was one of its “RevCons,” NASA-speak for revolutionary concepts, and was funded as a project aimed at jump-starting the most promising high-risk, high-payoff technologies. Especially in the supersonic regime, the PDE —with thrust coming from a high-pressure shock wave rather than an ordinary flame—was a perfect bridge between conventional jet engines that start to sag past Mach 3 and scramjets/ramjets that work well at high speeds but need help to get under way.

Dave Richwine, Dryden’s project manager at the time, crowed about the “exciting opportunity” to demonstrate a pulse detonation engine in actual flight, “one of the first steps in development of this engine cycle for many future supersonic” vehicles —from missiles to high-speed aircraft.

Then, like so many other projects before it, this one fell out of the government’s budget ledger. No hardware flew. Papers were published, noted, and filed. Even the relatively budget-rich U.S. military wound up yanking money from its own PDE-powered high-speed missile efforts, with which the Boeing team was also connected.

Now, seven years later, some of the top scientists and engineers in the field say that with the right economic incentives and a few well-placed technology leaps, they could get to a flight-ready system in five years. High jet fuel prices and the approaching limits of conventional turbo-machinery have set off another push, pitting two giants in the aircraft engine industry—General Electric and Pratt & Whitney— against each other. Thanks to generations of work and continued efforts in the early part of this century by engineering heavyweights, the pulse detonation engine, the Next Big Thing for decades now, may this time really be just a few years away.

PULSE DETONATION, depending on whom you talk to, is either (A) not yet quite practical but really attractive, or (B) the super-secret propulsion behind the U.S. military’s spookiest “black” airplanes and missiles. It’s probably closer to A than to B.

The pulse detonation engine is a refinement of an old, very simple technology: the pulse jet. Pulse jets became notorious as the power behind Germany’s World War II-era V-1 buzz bombs. The rockets were simple, cheap, gas-guzzling, and extremely noisy. The buzz bomb went by several names. English speakers called it the Doodlebug, but Nazi propaganda chief Josef Goebbels gave it the name that seemed to stick, the Vergeltungswaffe 1, or Vengeance Weapon 1. You can see one of these sheet-metal-and-plywood V-1s at the National Air and Space Museum in Washington, D.C.

During the war, the Germans lobbed thousands of these crude cruise missiles toward Britain and Belgium, using steam-powered catapults on ski ramps on the French and Dutch coasts. Powered by an Argus As014 pulse jet, the V-1 needed to reach a relatively high speed before its engine could operate. Not much more than a long tube, the engine had a simple flap at one end, like a doggie door but designed to open only one way. The flap served as an intake valve for air forced in by the missile’s forward speed. A simple system injected fuel into the tube. Once air and fuel were mixed into a combustible combination, the mixture was ignited, causing an explosion. The expanding pressure wave forced the doggie door shut and the gases exited at the rear of the tube. The series of controlled explosions gave the bomb its characteristic “buzzing” sound.

The PDE takes this idea one step further. The slow, gentle flicker of candles at dinner and the explosions inside the pulse jet share one characteristic: They burn subsonically, in a process scientists call deflagration. The process happens faster in an explosion than it does atop the candle, but nonetheless the chemistry takes place at speeds of, at most, tens of feet per second.

By contrast, detonation—the “D” in PDE—happens supersonically, with combustion occurring all at once. Detonation of a fuel-air mixture produces a high-pressure shock wave that speeds down the length of the tube at faster than five times the speed of sound. The shock wave itself creates a compression that instantly ignites fuel and air in the rest of the tube. As the exhaust gases exit from the tube, the pressure at the forward end drops. That pressure drop sets the stage for the cycle to repeat, dozens of times per second. The process is called pressure-rise combustion, and it’s a drastically different, higher-energy affair than simply burning a fuel-air mixture with a flame.

With jet fuel prices now three times as high as they were a decade ago, fuel economy is one of the chief motives behind the new interest in the pulse detonation engine. In theory, a PDE powering a next-generation aircraft could operate nearly as simply as the pulse jet, while being relatively cheap to build and vastly more efficient.

But simple on paper and simple in the real world are different things. The physics of this seemingly simple thermodynamic cycle prove to be exceedingly complex. Researchers at NASA, the California Institute of Technology, Pennsylvania State University, and Ohio State University have all struggled to accurately model the turbulent flow of air and fuel in a detonation chamber, the shock wave’s interaction with the chamber walls, and how those processes affect the speed of combustion.

There are engineering challenges too. Enabling just the right fuel-air mixture to appear at precisely the right time and at high frequencies—20, 40, or even 80 cycles per second—calls for control schemes and valves of the highest order of complexity. And don’t forget the most basic problem: Substituting detonations for the relatively gentle deflagration found in typical jet engines requires that the detonation tube be exceptionally strong. To be suitable for aircraft, the strong materials must also be lightweight, two characteristics that rarely go together. But the world’s leading engine makers think they’re up for the challenge to perfect the PDE.

IN THE 1970s, the annual contest between GE and Pratt & Whitney to win the lion’s share of U.S. Air Force fighter engine orders became known both inside the companies and at the Pentagon as the Great Engine War. In PDE research, their rivalry is no less fierce, and by many measures, P&W beat GE to the punch.

Pratt & Whitney jumped into the modern phase of PDE work relatively early, in the mid-1990s, when it worked on U.S. Navy projects as part of a Boeing team looking at new ways to power high-speed missiles launched from ships. The engine maker worked closely with a small company in Seattle widely acknowledged to be a modern-day pulse detonation pioneer, a startup called Adroit Systems. A few top Pratt & Whitney executives saw the future in the plucky company and its entrepreneurial founder, a former National Aerospace Plane program engineer named Tom Bussing. Bussing was a refugee from Boeing, and he explains the story of Adroit’s birth with an anecdote about Boeing’s Alan Mulally, then the president of Boeing Commerical Airplanes. (Mulally left Boeing last year to head Ford Motor Company.) When the NASP program was cancelled, Bussing says Mulally told him it would be more than a decade before Bussing would get a chance to manage a large-scale program. A short time later, Bussing left to form Adroit. A few years and several patents later, Pratt & Whitney bought it, rechristening it the Pratt & Whitney Seattle Aerosciences Center.

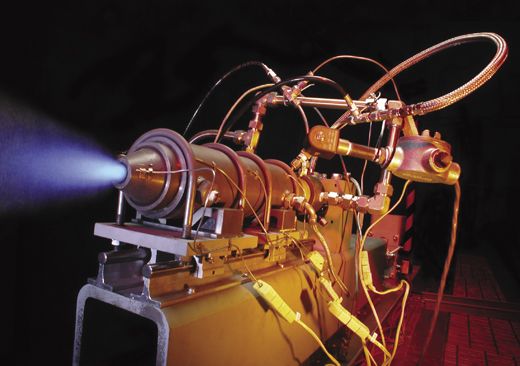

Pratt & Whitney has focused on valves as its approach to regulating the complex detonation sequence. The company’s five-tube test engine has a valve, patented by Bussing, that can rotate at 2,400 revolutions per minute to rapidly mix air and fuel, yielding 400 detonations per second. The valve isn’t the company’s only advance in PDE research. In 2003, Bussing and his colleagues fired an advanced pulse detonation engine on a rig at the Navy’s China Lake test center in California. Sim Austin, who heads Pratt & Whitney’s military engine special projects office, notes that last year “we demonstrated…how we could use PDE with fossil fuels”—military-grade JP8 or JP10 jet fuel—“without supplemental oxygen.” That was a key advance, made possible in part through work funded by NASA and the U.S. Office of Naval Research.

GE had a lot of catching up to do. Its answer to Pratt & Whitney’s advanced Seattle unit sits peacefully overlooking the Mohawk River in the bucolic upstate New York town of Niskayuna, between Schenectady and Albany. The campus luxuriates across 525 acres of rolling land, and, tucked in among comfortable homes and suburban cul-de-sacs, you can be forgiven for wondering whether the future really is taking shape anywhere near here. But it is.

“We are turbine-oriented, trying to go for the big prize, and doing it with liquid fuels,” says Anthony Dean, who heads the Propulsion Systems Laboratory at GE’s Global Research Center. An avid cross-country skier, Dean is the picture of a modern scientist who has left the pocket-protector stereotype behind.

Dean, like his company, came to the PDE party a bit late, but has worked hard to make up for lost time. GE, with financial interests in dozens of businesses ranging from appliances to locomotives and credit cards, has designated the pulse detonation engine as one of only six long-term technology areas meriting continued corporate research and development funding; it’s on a par with such hot areas as biotechnology and nanotechnology. With U.S. government money drying up for pulse detonation, that’s a good thing.

A lot of research programs in the field have occurred during the early part of this decade, Dean says, but “those government programs were four or five years, and they’re ending now.” The Navy’s Office of Naval Research, for example, had a multi-university research initiative which ended last year. Though there’s a lull in U.S. government funding, he says, “there’s still funding going on in Japan and a little bit in Russia.”

And there’s also funding at GE. “We’ve actually grown the program a little bit this year,” Dean says. He’s reluctant to give his competitors at Pratt & Whitney any hints of what that means in researchers and resources—“They might write that down and figure out what we’re doing”—but he’ll allow that GE’s PDE program is up “almost 50 percent” from 2006.

Those resources won’t be spent trying to plow the same ground already turned over in Seattle. “GE started eight years ago,” Dean explains, but “really actively started an advanced pulse detonation technology program” —the effort he now leads—“about five years ago. Most of our competition was focused on systems that use oxygen to begin detonation.” But because “you don’t want to carry extra oxygen,” he says, his team is focusing on avoiding that.

“In addition, there was no work around what happens when you try to combine this type of combustion with a turbine engine,” he adds. “At GE, we felt the real end goal was engines that were more efficient than today’s,” a concept in which pulse detonation technology inserted into an airplane’s turbine engine might make more sense.

When GE started looking seriously at pulse detonation engines, there was a lot of good theoretical work, particularly from Caltech, but it was of the single-shot variety: Fill a chamber, detonate it, and see what happens. Dean readily credits those engineers with doing “good science, but it didn’t give you a sense of the engineering challenges.”

Working with NASA, GE combined its PDE test rig with a large axial turbine pulled from a locomotive. Why not an aircraft turbine? The train engine “had the size we wanted, the flow we wanted, and for cost reasons,” Dean says. He and his team ran several configurations, and operated the machine with a test sequence of more than five minutes rather than just a few seconds. The long runs enabled the engine to reach a steady state of operation, “and to my knowledge, certainly with a turbine connected, that’s the first time that’s been done,” Dean says. GE’s rig had eight tubes for pulse detonation, each of which ran at about 20 to 25 cycles per second. “We got a million pressure cycles,” he adds.

It’s a bit of a journey, however, from a PDE rig bolted to a railroad engine to a flyable propulsion system.

“In five years, you could have a flight-weight demonstrator,” Dean says, noting that if the government signaled its commitment with additional funding, “I think GE would pony up its resources, and the other guys would too.” At the beginning of the decade, some scientists said there could be a flying demonstrator by 2010, but “no way are we going to make 2010 at the current level of investment,” he says. “This type of stuff requires a lot of effort, a lot of money. Even GE, a big company, will only go just so far ahead of its customers. We’ll only go so far ahead of where the government is… In fact, [the government] is pulling back on its own internal effort at NASA labs.”

But is it? It’s not a stretch to believe that PDE technology is ready enough to submerge itself into the murky world of what the Pentagon calls “black programs.” These are programs that don’t exist—at least not publicly—and yet they do. The bat-wing B-2 stealth bomber, for example, was a black program, as was the stealthy F-117 Nighthawk. The closest near-term application for a pulse detonation engine was a proposed high-speed missile, and the missile remains the most likely place for a PDE to emerge first, military officials and researchers agree. The U.S. military budget shows money earmarked for such umbrella programs as “Propulsion Technology Initiatives,” and in-house funding continues for propulsion research led by the Office of Naval Research and the Air Force Research Laboratory. And the big players like GE and Pratt & Whitney still continue to put as much of their own money in as they can, without “getting ahead” of their government customers. That suggests that what the companies are spending on PDE research is in line with what their government sponsors expect it to be.

Gary Lidstone, a colleague of Austin’s at Pratt & Whitney’s Seattle unit and the division manager there, says that meanwhile, “all of us are still working independently to garner funds for the technology development.” Austin says he and others are “working that issue” with the officials at the government labs who write the checks, hoping to get some early funding later this year or early in 2008. A lot of smart people are betting that the money will come from the missile world, especially given the technology-readiness gap between the PDE for missiles and the more complex concept for a hybrid commercial aircraft engine.

NASA, the U.S. government, and lots of tech companies worldwide use a numeric scale to rank the risk or readiness of technologies. The scale starts at 1 for the lowest level of technology readiness and climbs to 9 for fully operational. Lidstone says the engineering community figures the readiness level for PDE hybrid commercial aircraft engines is “in the two or three range,” while for the “missile activity, it’s three or four.” In Pentagon parlance, “three or four” means you’ve tested all the pieces together in a lab to see if they work; five takes those tests to a more realistic, operational setting. Lidstone says that under his team’s development plan, the first use of PDE technology is probably a “small-scale, high-speed missile

application.”

The pace of current research and development points the way to three phases of pulse detonation engine technology, each a bit more complex than the one preceding it.

The first phase could be called the “pure PDE”: Essentially it focuses on developing the detonation tube, which would power a very-high-speed, air-breathing missile. In this application, engineers and scientists can punt on two of the biggest technology problems—life, or the durability of the system, and noise. The missile has to fly only once, so long life for the metals or components is not a concern. And at the high speeds—around Mach 6—and altitudes in which the missile would operate, less noise is also moot. This is the area in which Adroit Systems, and later Pratt & Whitney, made the most strides. It was their machine that would have been flown on NASA’s F-15B.

The next phase could involve using pulse detonation engines to address another pressing issue in combustion: afterburners for fighter aircraft. Today’s fighter engines simply spray aerosolized fuel into a long tube aft of the turbine section, literally dumping extra fuel-air mixture into the hot gas stream for a brief extra kick of speed. Engineers think that if they add pulse detonation technology to a low-bypass-ratio turbine engine—the modern fighter jet engine—they can get the efficiency benefit of pressurized, shockwave combustion. It’s relatively simple because the pulse detonation tube would be at the end of the engine and not in the middle of the turbo-machinery. Here again, life and noise are less of an issue than they might be in a commercial aircraft. Fighter pilots only fly on afterburner about five percent of the time, and anyone who has seen an airshow knows fighter jocks usually don’t worry about making a racket.

The third phase is where it gets most complicated, but is the one that may offer the biggest payoff: pulse detonation in the middle of the engine. Having a compressor upstream and a turbine downstream, says GE’s Dean, is a potential high-value payoff that keeps his company attracted to PDE development. A PDE-based combustor is one of the main areas of work for a young researcher on Dean’s team named Adam Rasheed. Rasheed is chronicling his work on a publicly available blog, “From Edison’s Desk” (Massachusetts Institute of Technology’s Technology Review magazine in 2005 named Rasheed one of the world’s top 35 researchers under the age of 35.

Like everyone else, Rasheed has his eyes on a jet engine that burns five percent less fuel—an enormous leap compared with today’s fuel-saving techniques. He suggests in his blog that after 50 years of tweaking, aeronautical engineers may be close to wringing out the very last ounce of performance from today’s jet aircraft engines. In a world in which efficiency improvements of even 0.2 percent are considered a major breakthrough, “PDEs represent a possible game-changing technology that could revolutionize aerospace propulsion,” Rasheed writes. Even a one percent improvement would save hundreds of millions of dollars in fuel. And by reducing the amount of fuel they burn, PDEs produce fewer emissions and gases, making for a greener propulsion technology (see “Fly Green,” September 2007).

That five percent in fuel savings is the tantalizing prospect that drives Dean and his colleagues, as well as his rivals in Seattle and at Pratt & Whitney’s home base in East Hartford, Connecticut. The two engine makers, along with the third major manufacturer, British-based Rolls-Royce, all see the end of the jet engine as we know it. To be sure, there’s debate about the pace of that change. Pratt & Whitney’s Austin cautions that no one should be ready to count out the modern aircraft gas turbine engine just yet. He believes that there are still efficiencies to be gained in how the engines are fitted to and optimized for air vehicles, and in how the components go together.

But most engineers agree that while it may not happen today, or tomorrow, or even next year, it’s coming as surely as the automobile put the horse-drawn buggy out of business. And that’s why they’re all working so hard to find ways to bring pulse detonation technology out of the realm of scientific papers and into the working world.

While U.S. funding may have slowed, that’s not true everywhere. Dean recently spoke at a conference in Reno, Nevada, sponsored by the American Institute of Aeronautics and Astronautics , and he was surprised to see that 45 papers on pulse detonation engines were presented. The sessions were well attended, and Dean saw many familiar faces in the crowd —colleagues from Lockheed Martin, Boeing, and others long involved in some aspect of high-speed flight research.

But “there’s clearly a bunch of new people looking at it for the first time,” he says. “I think what surprised me was the level of interest from Japan. We’re doing good work [in computational fluid dynamics], [but] their level of prediction for detonation phenomena was just terrific.” What do those “new people” see? Quite possibly, the engine cycle that will power the next 100 years of flight. No one wants to be left out this time around.