Who Says a Jet Can’t Be Cheap?

Gerry Merrill says he can build you one for $150,000

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Cloudster-631-mar08.jpg)

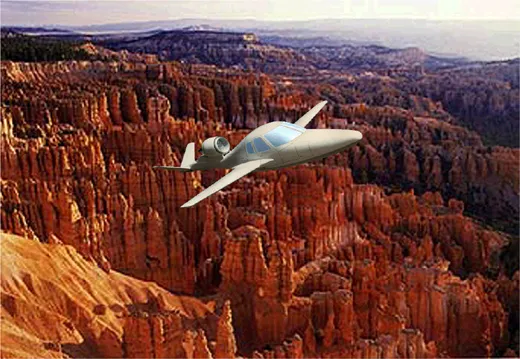

Taped to the wall of Gerry Merrill's office in Phoenix, Arizona, is a three-view engineering blueprint of a sleek, two-seat personal jet. Finely curved, it sports a V-tail and a single fat engine nacelle atop the rear fuselage. Merrill, a wiry 73-year-old, tells me that, compared to current propeller-driven light airplanes (which he dismisses as "archaic crap"), the airplane on his wall will fly twice as fast, get better fuel mileage, and be 30 times quieter. His proposed family of jet-powered light airplanes, he says, will revolutionize private aviation, if only he can raise the $120 million it would take to get them certified by the Federal Aviation Administration and into production.

The good news: "This is potentially a multi-billion-dollar business," he says. The bad: He can't break into the market.

Since the 1940s, jet engines have revolutionized military, airline, and corporate flying. But somehow, the jet revolution never trickled down to personal flying. A practical, affordable, jet-powered light airplane for private pilots—a Cessna Skyhawk, say, without the propeller—has for decades been only a dream. Five- or six-seat, $1.5 million to $3 million very light jets (VLJs) are just now on the market, but the vision of a single- or double-seat jet with the price tag of a propeller aircraft—one-eighth the cost of a VLJ—has never become more real than three-view drawings taped to the office walls of dreamers everywhere.

But Merrill stands apart from the rest; he probably knows more than anyone about small jet engines. A propulsion industry lifer who has worked on everything from torpedoes to funny-car dragsters, he's had a hand in the design of some 80 jet engines, ranging from the General Electric J79, used in U.S. fighters and bombers in the 1950s and 1960s, to the Teledyne CAE J402, used in today's air-to-surface and cruise missiles. But for more than 40 years, his abiding passion has been the idea of a small jet engine for light aircraft. He has spent most of that time bouncing back and forth between manufacturers, who weren't willing to bet the store on an engine that was not certified, and investors, who wouldn't put up the money for certification because the light-airplane market was too unpredictable.

Conventional wisdom holds that jet engines burn too much fuel at low altitudes to be suitable for light aircraft. Jets, it's said, are efficient only above 30,000 feet or so, where light airplanes fear to tread. "That's bullshit," says Merrill flatly. Sure, every jet flying today gulps prodigious amounts of fuel when going low and slow. But that's because they were all designed to run high and fast. The secret, Merrill says, is to simply optimize the configuration of an engine's turbines, compressors, and fan for, say, 250 mph at 15,000 feet instead of 500 mph at 40,000 feet. "It's not rocket science," he says. "My engine technology and materials are basically 1960s. The breakthrough is conceptual."

The results of optimizing a turbofan engine for low and slow are breathtaking—on paper, at least. According to Merrill's numbers, his theoretical 490-pound-thrust turbofan would, at 10,000 feet, push along his theoretical two-seat Cloudster airplane at 270 mph while burning 12 gallons of fuel per hour. That's 22 miles per gallon—about the same fuel efficiency that Cessna claims for its two-seat, propeller-driven 152, which flies not even half as fast. Climb to 23,000 feet, and the Cloudster will do 220 mph while burning seven gallons per hour. That's 31 miles per gallon. So much for the notion that jets at low altitude suck too much fuel, Merrill says.

Two primary factors account for the amazing low-and-slow fuel efficiency of Merrill's turbofans. All have extremely high bypass ratios and very low fan pressure ratios. (The bypass ratio is the amount of the air that passes through the fan—known as "cold thrust"—compared with the amount that passes through the core, or combustion chamber —"hot thrust." Typically, the higher an engine's bypass ratio, the better its fuel efficiency.) Merrill's engine for the Cloudster on his wall has a bypass ratio of 19, which is five or six times that of the current crop of VLJ engines, and double that of the most advanced jetliner turbofans. Merrill calculates a specific fuel consumption of around 0.30 pound per hour per pound of thrust—an extraordinarily low number, and one that is 50 percent better than the current VLJ mainstay engines, the Williams FJ33 and the Pratt & Whitney PW600 series.

But the real breakthrough in Merrill's engines is in their low fan pressure ratios. The ratio of pressures across the fan stage is a rough indicator of how much kinetic energy is wasted as air passes through the fan. "You've got to match the fan pressure ratio to the airspeed," says Merrill. "The lower the speed, the lower the FPR." Merrill is cagey about disclosing his engines' precise fan pressure ratio, but claims it is much lower than that on the VLJ engines.

Merrill estimates the cost of a production engine at $44,000, about the same as the price of current piston engines of similar power. But the estimate is dependent on a production run in the thousands.

The other aircraft in the Merrill line have similarly surprising numbers. A four-seater powered by an 800-pound-thrust engine could hit 280 mph, and get up to 22 mpg. That's better fuel economy than current four-seat prop airplanes, which fly 100 mph slower. Merrill figures such an airplane, once in large-scale production, would cost about $450,000, roughly the same as a current Cirrus SR22-GTS four-seater. He estimates that his single-seater, weighing just 320 pounds empty, would cruise at 220 mph, get 55 mpg, and cost just $150,000.

Emmett Kraus, a retired manager of advanced design at Cessna, thinks Merrill's calculations are more than just wishful thinking. "He knows what works and what doesn't," says Kraus. "His program makes a lot of sense. I've studied his performance and pricing claims, and I think they're pretty reasonable. With all his hands-on experience in the industry, he's in a better position than most startups to accurately predict his prices. By far."

His slick airplane designs notwithstanding, Merrill's engines alone would seem to have the potential to revolutionize personal flying. It's an industry axiom that engines beget airplanes, and history suggests that if Merrill can ever get the engine built, the airframe makers will come, in droves. For the past 35 years, every time the jet engine bar has been lowered, the smaller, cheaper jet that results quickly becomes the fastest-selling ever. In 1971, it was the Pratt & Whitney JT15D and the Cessna Citation. In 1993, it was the Williams FJ44 and the CitationJet. Today, it's the Pratt & Whitney 610 and the Eclipse 500.

As a kid growing up in Michigan during World War II, Merrill was obsessed with aviation. At age 12, his design for a 50-passenger turboprop won a prize from Air Trails magazine. Mesmerized by a Lockheed P-80 Shooting Star at a post-war airshow, he decided he'd rather help create fantastic jet airplanes than fly them.

Merrill was hired by General Electric right out of high school, and went to work as a draftsman in the engine development department. At night he attended the University of Cincinnati, and by day he worked on the GOL1590, a prototype jet fighter engine that spawned the J79, which powered the F-104 Starfighter, F-4 Phantom, B-58 Hustler, and A-5 Vigilante. Then came gigs at Chrysler, Curtiss-Wright, and Smith-Morris, a jet engine component supplier. In 1963, he took a job as a senior design engineer at Teledyne CAE, at the time the leading U.S. manufacturer of small jet engines. He and Tom Foster, a designer who'd been a student of jet propulsion pioneer Frank Whittle in England, became Teledyne's preliminary design department.

It was here that Merrill first launched his quixotic quest to create a small turbofan for private airplanes—and where he first felt the sting of rejection and betrayal. In 1966, Foster and Merrill started work on a small general aviation jet engine. Their design for a 1,300-pound-thrust turbofan with a bypass ratio of 3:1 was a radical departure from the general aviation jet engines of the day—noisy, fuel-hungry turbojets with around 3,000 pounds of thrust. When Foster and Merrill first pitched their idea for a quiet, fuel-efficient turbofan to Cessna, the company was interested. But Cessna president Dwayne Wallace kept asking for more power, Merrill says, and the proposed Teledyne engine eventually grew to 2,100 pounds.

But then, according to Richard A. Leyes' book, The History of North American Small Gas Turbine Aircraft Engines, "Wallace...called Bill Gwinn, president of United Aircraft Corp., explaining that Cessna wanted to build a small jet, and that they wanted a Pratt & Whitney engine on it. Gwinn then called Pratt & Whitney Canada president Thor Stevenson, and the next day P&WC engineers were designing their first fanjet engine."

"Wallace wanted a screaming eagle logo on the nacelle," Merrill says bitterly, referring to the Pratt & Whitney logo. "So he passed on the specs of our engine to Pratt & Whitney." Whatever the case, in 1969 Pratt & Whitney delivered to Cessna the first JT15D, a 2,200-pound-thrust turbofan with a bypass ratio of about 3:1. Cessna used it to power its new Citation 500, which quickly became the world's best-selling business jet. The JT15D is still in production today.

The pattern for Merrill's coming decades of frustration was beginning to take form: Good idea, but no cigar.

In 1971, Merrill moved from Teledyne to Garrett AiResearch's advanced technology office. One of his projects was a refinement of the original Teledyne concept, a 1,300-pound-thrust turbofan. He offered it to Cessna for a downsized version of the Citation. Then-CEO Mal Harned turned down the idea, choosing instead to proceed with the ill-fated Conquest turboprop. Thirty-six years later, Cessna introduced the Mustang, a downsized version of the Citation with 1,300-pound-thrust Pratt & Whitney engines.

Merrill left Garrett in 1984 to pursue his vision of a practical light-airplane turbofan on his own. For the next three years, under the auspices of his contract engineering firm, Advanced Propulsion Inc., Merrill peddled his ideas to virtually every general aviation airframe maker in North America. He got nowhere. The light airplane industry was then in a state of virtual collapse, and "they were too busy just trying to survive," Merrill says.

Working with old industry friends, Merrill designed a family of small jet aircraft around his engine concept, ranging from a 260-mph single-seater weighing just 760 pounds to a 10-seat executive jet. He called the project Private Jets.

In 1991, a friend introduced Merrill to Donald Douglas Jr., son of the Douglas Aircraft founder. Then 75 and retired from 20 years in the executive suite of the family business, the gruff, no-nonsense Douglas listened intently to Merrill's 45-minute pitch. "He got it immediately," recalls Merrill. A few weeks later, Douglas agreed to use his name and industry contacts to help Merrill raise money. The company was renamed Douglas Private Jets.

Douglas set up meetings with a number of old buddies. There were some tantalizing negotiations, but once again, nothing came of them. Increasingly frustrated with the turndowns, Merrill and Douglas drew up a plan in 1993 to tap a new source: the U.S. government. That June, they gave a two-day briefing to engineers and managers at NASA's Lewis (since renamed Glenn) Research Center in Cleveland. Nice presentation, they were told, but no money available there. Undeterred, the pair went to Washington, D.C., and started knocking on doors. After two years of pleading that included audiences with NASA chief Dan Goldin and FAA boss David Hinson, Merrill and Douglas pulled off what appeared to be a stunning victory: Congress appropriated $37.25 million for a NASA research program based on their Private Jets concept.

The research effort was assigned to the Lewis center and renamed the General Aviation Powerplant, or GAP, program. According to a NASA press release with hyperbole matching that of the flip charts Merrill showed potential investors, GAP's goal was to "reduce the cost of small turbine engines by a factor of 10 and revolutionize the concept of personal air transportation." Just one catch: GAP was to be opened up to bids from the industry. Suddenly Merrill was going up against the big boys again. And there was another problem: Goldin's philosophy that the agency should take care of its "customers"—the established engine manufacturers that it had been working with for years.

Merrill tried to partner with several manufacturers, but in the end, Douglas Private Jets went it alone. Williams International won the GAP contract with its FJX2, a cutting-edge turbofan that worked fine in the test cell but flopped when the company tried to turn it into an engine for the Eclipse 500. It has since disappeared (see "The Little Engine That Couldn't," Oct./Nov. 2005).

"NASA stabbed us in the back," says Merrill. "Instead of an engine for a 200-knot, 20,000-foot lightplane like we proposed, they ended up with an engine for a small business jet that cruised at 41,000 feet. Even if it had worked, it wouldn't have revolutionized a damn thing."

Sour grapes? NASA's Leo Burkhardt, the GAP program manager, confirms Merrill's role in getting the GAP ball rolling. "Gerry's advocacy opened our eyes to the potential of small turbofans," he says. "Gerry made it happen. I give him total credit for that." Burkhardt says he considered Merrill's proposal technically feasible but felt that Williams' design was more advanced. "Of course it was more advanced," retorts Merrill. "That's why it failed. The whole point of our engine was that it was all proven technology, but optimized for the low-and-slow regime."

Don Douglas died in 2004, and Merrill has carried on with occasional help from Douglas' younger brother Jim and other industry friends. He still gives presentations now and then at the Experimental Aircraft Association's annual fly-in at Oshkosh, Wisconsin, and is currently targeting a potential investor in the Persian Gulf. Although Merrill's enthusiasm for his crusade shows no signs of spooling down, he seems resigned to his 40 years of failure. "People get interested, but everywhere you turn, the capital always seems to be committed to other projects," he says. "To people with money, we're just bothersome pissants."

Bruce Holmes, the cerebral former NASA general aviation soothsayer, puts it a bit more delicately. "It comes down to the investment culture these days," he says. "Going from slow little planes to fast little planes really changes the paradigm. That's too unpredictable for most investors."

That's because most investors are cautious by nature, says Richard Aboulafia, an analyst for the Teal Group, an aerospace investment consulting firm in Fairfax, Virginia. "Investors are willing to underwrite incremental improvements, but not great leaps forward like Merrill's," he says. "The [market is] too unpredictable, and that scares them off. You need slam-dunk numbers to attract money, and investors don't see that kind of potential in the lightplane market. They want to see numbers like the bizjet market, which has more than quadrupled in the past decade."

Another problem for Merrill, Aboulafia says, is that "he's a small startup company. The history of this business is that the big guy wins. An investor would be very leery of putting money into a small company with a new engine technology like this, only to watch Pratt & Whitney come along and take over the market."

Even the newer, more visionary aviation companies seem wary. "It's ingrained in our core, our company culture, that the engine has to be there, certified and proven," says Mike Van Staagen, vice president of advanced development for Cirrus Design. Cirrus recently unveiled a mockup of a single-engine personal jet, but it will use a standard high-and-fast Williams FJ33 engine. "We closed the door on Merrill because it was just too big a leap. To hinge the entire company on an unproven engine is just something we're not willing to do."

With their V-tails and top-mounted single nacelles, both the Cirrus mockup and Eclipse Aviation's new single-engine, four-seat Concept Jet, introduced with much fanfare at last year's Oshkosh show, look to be straight out of the Merrill playbook. Underneath the skin, though, the new Eclipse is still a 400-mph, 41,000-foot, million-dollar machine powered by a high-and-fast turbofan. Merrill's low-and-slow market niche remains wide open, waiting to be filled by somebody with enough money and vision.