Last Breath

As NASA prepares to shut down a historic wind tunnel in Virginia, some hope for a stay of execution.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Langley-Tunnel-flash.jpg)

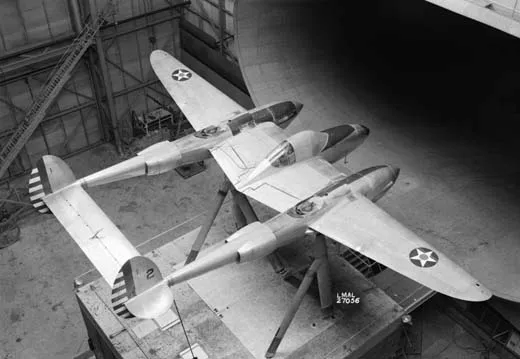

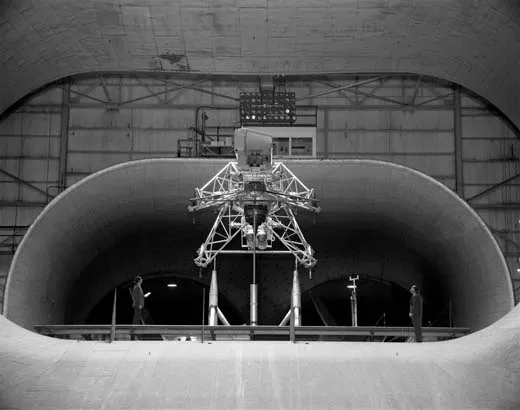

Ken Hyde remembers his first trip a decade ago to the full-scale wind tunnel at NASA’s Langley Research Center in Hampton, Virginia. Hyde, famous for constructing a flying replica of the Wright brothers’ 1903 Flyer, was testing his model of the Wrights’ 1900 glider. He was enchanted by the huge tunnel, whose test area was 30 feet high and 60 feet wide. Two 4,000-horsepower fans pulled air past the test rig at up to 118 mph.

But Hyde was equally enchanted by the can-do spirit of a group of aeronautical engineering students from nearby Old Dominion University, who were testing two NASCAR stock vehicles side-by-side in the tunnel for a private client. Under a Space Act agreement with NASA, ODU’s aeronautical engineering department had been granted use of the tunnel since 1997.

“We’ve got so many sharp minds out there, but they need the tools,” says Hyde today, lamenting the coming demise of the wind tunnel, which has been in operation since 1931. Friday, September 4 saw its last day of testing, with Boeing studying how air flowed around a scale version of its X-48C blended wing body concept. Soon after, Boeing began dismantling the 400-pound model. By the end of the month, the ODU team will vacate the facility for good. NASA soon will bid out the demolition job to a contractor, and the building will start coming down most likely in January.

With the tunnel will die a legacy of testing biplanes, sailplanes, X-planes, submarines, lifting bodies, Mercury capsules, supersonic transports, racecars, tractor-trailers, and modern wind-turbines (for green power research). Orville Wright, Charles Lindbergh, and Howard Hughes were photographed inside the tunnel, which was designated a National Historic Landmark in 1985. But it has to go, says NASA, claiming that the tunnel has outlived its useful life.

Hyde’s angle is a bit different. “ [Langley] had about 40 highly paid engineers [assigned to the tunnel] with not enough work to do,” he says, which drove up the cost of using the facility. When ODU took it over, the operation became leaner, giving the tunnel a second life it otherwise may not have had. The engineering group from ODU went out and found clients who needed aero research, including Penske Racing, which alone brought in $250,000 a year for several years. The money covered the university’s costs of operating the tunnel, with some left over to fund other graduate aeronautical research. The hourly rate for customers ran $1,600 an hour. If that sounds steep, it’s a good deal cheaper than the country’s largest wind tunnel, now operated by the U.S. Air Force, at NASA’s Ames Research Center in California. A Canadian green power firm that wanted to test turbines in the Langley full-scale tunnel was given an estimate of $56,000 total. The estimate they got from the Ames tunnel was $200,000.

Hyde, whose appreciation of classic flying machines is obvious, likes the Langley tunnel for more than its history. He insists it’s still in good working order and in great demand, a point that’s hard to deny with Boeing testing its most futuristic blended wing design right up to the deadline.

“Computational fluid dynamics [CFD] software is fine for designing airplanes,” says Norm Crabill, who in 1949 joined the National Advisory Committee for Aeronautics, which became NASA. He retired from NASA in 1986, and started Aero Space Consultants, a sole proprietorship not far from the research center. “I’ll bet you that Boeing has the best CFD program that you can find. But to really firm up what they’re doing, what do they do? They go to a wind tunnel.”

Several years ago Crabill used the full-scale tunnel to test the canard—the small horizontal wings—on the front of the Wright Flyer. He was able to obtain data on the stick force needed to keep the canard from stalling—information the Wrights never had.

“I believe we got valuable insights into the handling qualities from the tunnel, and you could not get that from CFD. That airplane [the Wright Flyer] is so flexible. It’s got a bunch of wires holding it together. CFD is great for a streamlined body that’s rigid, where you can represent the surface mathematically. You cannot do that with the Flyer. You have to put it in the tunnel and see what happens.”

If solving the riddles of the Wright Flyer isn’t high on NASA’s to-do list these days, Jim Cross remembers another project ODU carried out in the tunnel that potentially helped save airplanes and lives. In 1997, as the dean of the College of Engineering and Technology, he approached the director of Langley about bringing in engineering students for hands-on learning. Their first problem involved some of the Air Force’s F-15s, which were misbehaving during slow landing approaches at high angles of attack, suddenly experiencing a hard rudder input from the computer that left pilots very skittish. “The pilots called these ‘evil planes,’ ” says Cross. The ODU team, in conjunction with NASA, put the nose of an F-15 in the tunnel and found the problem. A plug, or nose cap, in the tip of the nose—“It looked just like a wood screw,” says Cross—was the culprit. If it wasn’t screwed in properly, or was damaged or misaligned, it caused an aerodynamic disturbance down one side of the airplane that compelled the flight computer to command the rudder input.

Useful as these studies may be—and profitable—the tunnel still has found itself at times literally underwater. “What finally caused a major disruption in our productivity was the hurricane,” says Cross, referring to Isabel in September 2003. “We had three feet of water in the wind tunnel. That shut us down for four months. The race teams were forced to find other tunnels. We never fully recovered.”

According to the current ODU team leader, Bob Ash, who took over from Cross about three years ago, the storm did $600,000 of damage. About $200,000 in federal emergency disaster relief came through NASA, while the rest was paid for by the Commonwealth of Virginia and insurance. Since Isabel, three nor’easters have flooded the tunnel less severely.

“Why are they closing the tunnel?” asks Ash. “The easy part is that it is so precariously situated near the water. Short of moving a 2.2 acre facility, they’ve got to take it down because of the rising water level in the Back River. Most people think [the rise] is due to global warming.” Ash cites a recent report from the Virginia Institute of Marine Sciences that charts roughly a foot of increase in the water level at Sewell’s Point, about ten miles away, from 1928 to 2007. He’s resigned to the tunnel’s eventual closure, but like many, hopes for a little more time. “Our position has always been: We’re very proud to run this thing. We think it still has a few miles left in it. NASA notified us over a year ago, so we knew it was coming. But it continues to be my opinion that if NASA could let the tunnel die a natural death, then we could still do some unique and valuable testing here.”

Ultimately, the Air Force may be applying some quiet pressure, as the tunnel sits on land that belongs to them. “The Air Force thinks it’s ugly,” says Jack Ralston, president of Bihrle Applied Research, a local engineering firm that rents time in the tunnel. “If it weren’t on their property, it probably wouldn’t be a problem. Everything’s really spit-polished at Langley Air Force Base because it’s the headquarters of Air Combat Command.” He too realizes that the tunnel can’t live forever, but has written his congressman for a stay of execution. “Why stop the facility from operating before they [NASA] have the bid to show the government that they’ve got the demolition contractor in place? As long as it’s standing there, it might as well run.

“I think it’s been kind of an orphan,” he continues, “step-child, whatever you want to call it. NASA and the Air Force don’t want to deal with it.”

Kathy Barnstorff, a NASA spokeswoman, says that NASA’s part of the agreement with ODU was to maintain the exterior of the wind tunnel “only to a level of safety. Once NASA decommissioned the [tunnel] in 1995, NASA has done little to maintain thet vacility except as it applies to safety. That includes items such as fire suppression system upkeep and sandbags to curb flooding.” This she says, costs NASA about $4,500 a year. The agency also made a one-time investment on $36,000 to replace damaged windows with plexiglass. The building’s exterior, a mix of asbestos and concrete, is dilapidated.

Barnstorff points to a combination of factors that have, according to NASA, rendered the tunnel obsolete: the growth of computational fluid dynamics, less money in NASA’s aeronautics budget over the past decade, and industry consolidation that has left fewer airplane manufacturers in need of tunnel time. Barnstorff reasons that Boeing chose the tunnel for its X-48C only because they had tested its predecessor here in 2006. “We already had a database from the full-scale tunnel, so it was logical for them to send the X-48C here so we could compare apples to apples.”

Accurate cost estimates for the demolition won’t come in for a month or more, and will include destruction of three smaller decommissioned wind tunnels at the center. But estimates for all four tunnels in recent years, says Barnstorff, have run from five to eight million dollars. A bit more than half of that, she supposes, might cover the full-scale tunnel.

What will replace the building? “That’s up to the Air Force to decide,” she says. Rumors are that a parking lot lies in the immediate future.

As for Hyde, he’s getting the word out via a web page, and has hope that NASA won’t do something irreversible, such as remove a propeller blade from one of the fans as a gift to a museum. He knows it can’t live forever. He simply wishes NASA would let ODU operate the tunnel, occasionally fixing it “with a crescent wrench and a screw driver.

“If it finally reaches a point where it isn’t repairable,” he says, “when that day comes, I’ll help ’em load it on the truck.”