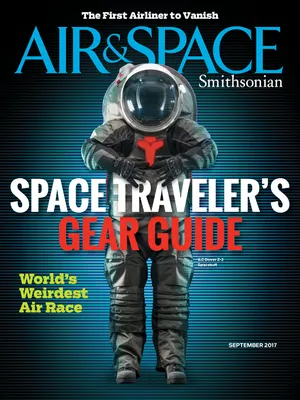

Super Helmet

F-35 pilots get X-ray vision and other magic powers.

:focal(1596x1014:1597x1015)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/ac/2c/ac2c7d0f-a5d8-433e-ab14-c4253ff4982e/06a_sep2017_baseviewhelmetw-obackground_live.jpg)

At a 2015 press briefing, Air Force Chief of Staff General Mark A. Welsh III was at a loss for words. “The helmet is much more than a helmet, the helmet is a workspace,” he said of the headgear invented for pilots of the Lockheed Martin F-35 Lightning II. “It’s an interpretation of the battle space. It’s situational awareness. Calling this thing a helmet is really…we’ve got to come up with a new word.”

Wired magazine tried out “head unit.” The Economist: “Top Gun’s Topper.” Whatever it’s called, the thing is loaded. It combines a sensor suite, night-vision technology, an information-packed display system, line-of-sight tracking based on head movement, and targeting software—all designed to give pilots a god-like view: everything, everywhere, for the pilot to select to avoid sensory overload. Whereas fighter pilots once checked a head-up display on a fighter’s windscreen for information such as airspeed, heading, altitude, rate of climb, and information about other aircraft—friend and foe—in the same piece of sky, the F-35 pilot sees all this and more on the helmet visor. A pilot can either tap a touchscreen on the cockpit avionics panel or press a single button on the F-35 control stick to choose among three feeds: real-time video of what’s going on outside, thermal imagery, or night vision.

The helmet has the almost creepy capability of following the pilot’s gaze. As her head moves, so moves the data feed, presenting video from a suite of six cameras located on the F-35 airframe. The distributed aperture system—one camera is mounted ahead of the cockpit, another is aft, and the remaining four are below the airframe—gives the pilot the equivalent of X-ray vision: When she looks down, she can see straight through the floor of the airplane. One pilot, unimpressed, pointed out that he could achieve the same perspective by quickly rolling the airplane into a steep bank and looking out the side of the cockpit. But when the F-35 helmet shows the pilot the ground sliding by beneath, it can overlay that video with a flight path to the destination or with information about ground targets.

To follow where the pilot is looking, and in turn direct the appropriate view to the visor, the helmet must sense its position and orientation. It relies on a magnetic field, generated by a transmitter in the pilot’s seat. As the pilot’s head moves, sensors on the helmet detect a change in the field. Ideally the display would follow instantly and seamlessly, but in early generations of the helmet, the display lagged behind a change in head orientation. According to an April 2017 Government Accountability Office report, those problems have been addressed.

“There are a lot of factors that need to work well together,” says Joe Ray, a manager at Rockwell Collins–ESA Vision Systems, which provides the helmet display system. If the developers conduct a test and see a performance they weren’t expecting, he says, “we bring the pilots back in and we duplicate that [finding] in the lab.”

For targeting, an Elbit-developed system tracks the helmet’s position to determine where the pilot’s view is directed. If the pilot has selected the electro-optical targeting system (EOTS), the imagery he sees comes from sensors in a window beneath the cockpit that include forward-looking infrared cameras and infrared search-and-track radar. The system also supplies such information as target identity and distance—and even advises which weapon to use.

For the tracking system to work, the helmet must be precisely fit. A 3D scan is made of the pilot’s head and entered into a central database. From it, technicians develop software that drives milling machines to cut the foam liner by laser. A pilot’s eyes are measured with a pupilometer to align the optics package on the visor to within two millimeters of the center of each pupil to ensure that the images projected into his visor converge to his natural field of view.

When the pilot returns for the final fitting of the liner to its outer shell, the visor and its display feeds are adjusted to ensure that only a single fused image appears. Technicians spend four hours over a two-day period to shape the helmet liner to an individual pilot’s head in order to ensure that the helmet’s optical sensors are aligned with the pilot’s pupils. The measurements also ensure that the helmet rests on the pilot’s head so that its center of gravity is aligned with the pilot’s spine in order to prevent neck injuries during ejection or high-G maneuvers.

Although the helmet’s night vision is available with the press of a button—instead of the cumbersome process of donning goggles while trying to fly an airplane—this system too has run into difficulty during development. Night vision was a topic at a recent conference of the F-35 flight test safety committee, composed of F-35 pilots and engineers working on the program. The committee viewed a video from a November 2016 landing test that showed a helmet’s night-vision display that didn’t work properly. For the test, an F-35B, the short-takeoff/vertical-landing (STOVL) variant of the Lightning II, landed vertically on the amphibious assault ship USS America. The test pilot reports that “something was obscuring” the night-vision feed to his helmet-mounted display. The pilot nonetheless continued the test and landed safely.

Erik Gutekunst, a flying-qualities engineer at the test, says the incident gave him the “heebie-jeebies.” He adds: “It became very clear that the picture he was working with was unsatisfactory for any sort of operation in the very close vicinity of the ship.” The committee discussed making changes to the way the tests would be conducted, and the F-35 program office says software fixes to improve night vision will be tested this fall.

As of July, about 400 helmet systems had been delivered, and Rockwell Collins estimates that each of the approximately 3,100 F-35s on order will require 2.5 to 3.5 helmets. “Repair, attrition, wear and tear, pilots come and go,” explains Ray. Components such as the liners fitted to an individual pilot cannot be reused.

Because the helmet is custom-made and estimated to cost at least $400,000 each, pilots don’t use them during flight school and simulator training; they use mockups instead. Not until they are assigned to an active-duty F-35 squadron do pilots receive the most complex helmet ever made.