Now Even Kids Can Afford to Use the Space Station

A new company makes it easier to get your payloads to orbit.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Right-thisway-space-station-631.jpg)

Last July, Jeffrey Manber says, NASA and the American Astronautical Society shocked him by presenting his company, NanoRacks, with the International Space Station Innovation Award of the Year. “In the ’90s, people at Johnson Space Center were following me to the bathroom because I was working for the Russians, and now they’re giving me a medal,” Manber says, and pauses. “They still could be following me to the bathroom, I don’t know.”

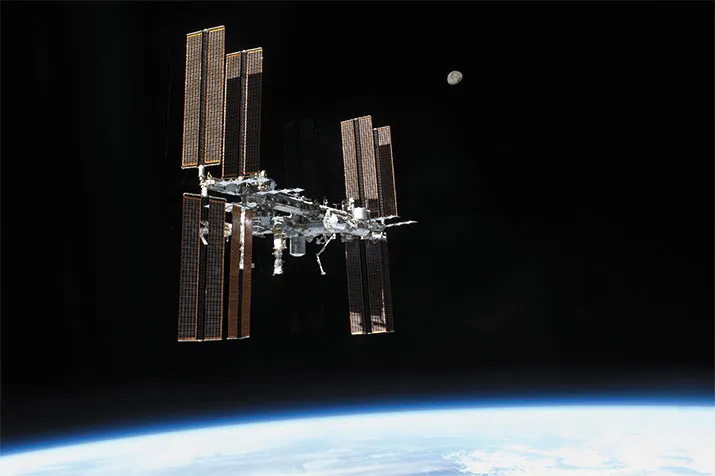

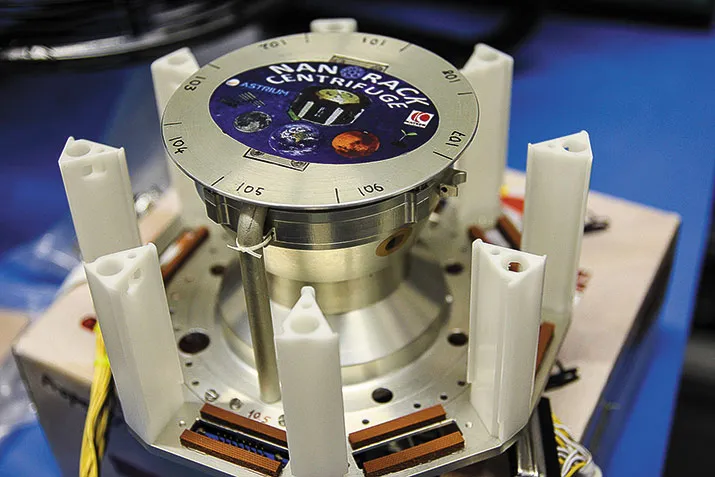

NanoRacks, which Manber established in 2009, provides a pioneering service for anyone who wants to place an experiment in space. The company is named for the platforms—racks—it built to house small science experiments on the space station. Now permanently installed in Japan’s Kibo module, two NanoRacks have a total of 32 locker spaces for small, cube-shaped laboratories—NanoLabs, the company calls them—that plug into the station’s power supply and data ports. But a NanoRacks customer gets more than a box for an experiment. The company offers advice about available equipment and instruction in how to use it—initially, with tutorials like “How to Build a NanoRacks Payload,” which can be downloaded from the company website. NanoRacks staff also perform the safety review required for station occupancy, get the box assigned to a launch manifest, fill out the thousands of pages of paperwork, provide support and data collection while the experiment is on the station, and, if required, make sure it’s returned to Earth.

“One of my goals is to Walmart space,” says Manber, in a voice that sounds a lot like Senator Chuck Schumer’s. “There is a strain of the community that still believes space is a cathedral…but today there’s no place for that sort of exclusivity. Our motto at NanoRacks is ‘Space is for Everyone.’ ”

When Congress established the station as a National Laboratory in 2005, 50 percent of the U.S. research area was made available for public use, but today only a little more than a third of that lab is being used for non-NASA experiments. Manber thinks he has the solution: Set prices that are not much different from the cost of research on the ground, protect your customer’s intellectual property, and provide 24/7 customer service.

“My whole career has been to make space just another place to do business,” says Manber, who got his start as a space businessman in the 1980s with PanAmSat. That company brought satellite communications into the commercial market by breaking the monopoly held by Intelsat, which at the time was run by a coalition of governments established by treaty. In 1992, Manber went to work for the Russians, heading the American office of Energia and representing the company as it competed for business in the post-cold-war international space industry. After nearly a decade, he moved to MirCorp, where he solidified much of his philosophy about doing business in space. “There’s nothing wrong with having advertising and sponsorship and commercial companies and schools, as well as government organizations,” working together to support space exploration, says Manber. Embracing this strategy, MirCorp negotiated deals to use Russia’s space station, Mir, commercially—with Dennis Tito to become the first space tourist, and with NBC to produce a “Survivor”-style show where the winner would visit the station. Mir was deorbited in 2001, before either came to be. (Tito later fulfilled his dream on the ISS.) “I learned at MirCorp what it takes to close a deal, a commercial deal that happens to be in space. That’s what I’ve taken with me to NanoRacks,” says Manber. He’s also brought what he learned from growing up in a family in the New York restaurant business: Keep your customers happy.

In 2009, Manber was one of the first to sign a Space Act Agreement with NASA to operate aboard the International Space Station. The agency began the program of competitively awarded partnerships to help get scientists, other researchers, and educators to use the space station for microgravity experiments. The agreement doesn’t award money but rather exclusive access to the station. NASA provides free transportation aboard any available station-servicing vehicle (the Russian Soyuz or Progress, Japan’s HTV, the European ATV, SpaceX’s Dragon, or Orbital Sciences’ Cygnus); in return, partner companies can earn fees from customers for help with the logistics of station research.

In 2011, NASA moved the administration of these agreements to the non-profit Center for the Advancement of Science in Space (see “The World’s Highest Laboratory,” Feb./Mar. 2012). NanoRacks is one of 22 microgravity research facilitators that CASIS calls implementation partners. All partners help researchers by providing either equipment or consultation, but NanoRacks is unique, says Duane Ratliff, CASIS chief operating officer. Instead of waiting for CASIS to refer customers to them, Manber and his colleagues seek them out. And instead of relying on NASA funding, Manber raised funds and invested his own money to build the hardware used aboard the station. That means the company “can actually treat this as a business opportunity where they charge a fee for service,” says Ratliff. “The hardware provides an analytical capability, and NanoRacks will arrange for the analysis to be conducted. That’s really a new way of doing business on the ISS.”

Says Manber: “We carved out in our Space Act Agreement that our customers own their patents. That’s not a trivial thing.” Besides that, he adds, the experiments are not subjected to peer review, as are experiments supported by NASA. “So you can try something different and novel,” he says, “and you don’t have to share. We have customers who are highly proprietary, including in the government, and they’re willing to pay money to avoid peer-group review, and they do this for competitive advantage.”

NASA imposes only two restrictions on a payload brought aboard the station: It must adhere to safety rules, and it must have a valid scientific reason to fly in space. “If one of the commercial companies decided to fly the latest and greatest My Pet Rock, that would not have met our [standards for] need of access to space,” says Jason Crusan, currently NASA’s director for advanced exploration systems, who negotiated the agreement with NanoRacks in 2009. Crusan admits, “There was probably skepticism at the beginning of whether or not a purely commercial entity would be able to uphold that standard, but [NanoRacks] has been very diligent about doing that.”

An early example of the company’s diligence: A NanoRacks customer wanted to do a perfume experiment in space. The experiment would likely have passed the safety tests, but NanoRacks chief technology officer Mike Johnson nixed it. Johnson had worked for Spacehab, the maker of cargo and experiment modules that rode to space in the shuttle cargo bay, and probably has as much experience with getting experiments into orbit as anyone in NASA today. He saw a minuscule chance that one of those vials of perfume might break, and he didn’t want his company to be remembered as the one that stank up the station for the rest of its orbiting life.

So what else wouldn’t pass muster? Flying up stacks of T-shirts or coffee mugs that say “I’ve been to space” and selling them in gift shops. Other than that, the opportunities for NanoRacks to market access to the station are wide open. Thus far, the company offers three types of station services: research space in the racks, small satellite deployment, and space on a platform scheduled to be installed on the station’s exterior in 2014.

The experiment boxes called NanoLabs have been the company’s bread and butter. They are sold in one-size-fits-all units, known as cube forms. A single unit is a box 10 by 10 by 10 centimeters (about four inches cubed); there are also two- and four-unit sizes. Each NanoLab box comes with a standard circuit board that activates the experiment’s procedures, like scheduled watering for seedlings, opening a control valve to mix fluids, or triggering a camera to take timed images. Once aboard the station, the box plugs into the NanoRacks, which provide power, water, cooling, and data recording.

The NanoLabs illustrate what Manber calls his “guiding principles” for opening space to commerce: standardization, miniaturization, and open-source interfaces, like the cubesat form itself. It was developed (in 1999, by engineers at Cal Poly and Stanford) to give researchers anywhere in the world not only a simple standard structure to use but also access to the original design so that they could easily modify or adapt it.

Carl Carruthers Jr., a researcher at the Houston Methodist Research Institute in Texas, is a NanoRacks customer who benefited from the fourth of Manber’s guiding principles: A company is only as good as its customer service. Carruthers studies protein crystal growth, an area of research that both Manber and Mike Johnson believe will bring them business in the future because it is especially suited to their company’s reliance on standardization. Characterizing a specific type of protein can lead to greater understanding of a disease or a genetic trait, so biologists grow them in repeating patterns, or crystals, until they become strong enough to withstand imaging. But this can be tricky. The proteins grow in a suspension fluid, and on Earth, the fluid is subject to convection and gravitational forces that cause the crystal to move as it forms. Though minuscule, these movements can result in irregular growth.

Many crystal growth experiments were flown on the space shuttle under the theory that the crystals might grow better when freed from the forces of gravity. But Carruthers flew experiments twice aboard the shuttle, and both times, he says, “I just got sludge back.” Determined to figure out why, he approached NanoRacks, which had provided the NanoLab, transportation, and support for his shuttle experiments; the tests had flown on the last two missions when the Kennedy Space Center was mobbed with visitors and it could take an hour just to get off campus. Says Carruthers: “These guys actually rented a mobile home and stayed in the parking lot so they could be there to help with our payloads. That just blew me away.”

Carruthers wanted to know why the shuttle experiments were using equipment that seemed decades behind the times. He suggested to NanoRacks that they use the same kind of standardized, miniaturized technology being used in labs around the world today. Manber and Johnson called up a biological research support company called Emerald Bio, which manufactures a microchip for holding fluids—it’s like a tray of test-tubes, only microscopic—that can be injected with protein solutions. A major challenge of growing protein crystals is that scientists don’t know what conditions are best for different proteins, and the only way to find out is to put each one in as many variations of conditions as possible. Emerald Bio’s microfluidic chip, about the size of a microscope slide, can hold 800 to 900 concentrations at once.

Earlier this spring, NanoRacks worked with Carruthers to fly a test with 25 chips containing close to 10,000 conditions, each one an attempt at protein growth. Because the microgravity experiment used standard industry equipment, Carruthers could easily run an identical control experiment on Earth. The shoebox-size experiment returned from space on a Soyuz and then made the long trip back from Kazakhstan to Carruthers’ lab. “I was floored,” the scientist says. “We had tons and tons of crystals. We had more crystals from the microgravity sample than we actually did on the ground.”

If it turns out that the protein crystals grown in microgravity actually lead to useful results—something still not yet proven—Mike Johnson sees the space station serving not just as a commercial research lab but also as a commercial manufacturer. “Protein crystal growth, that’s not really an experiment, that’s a thing we’re mass-producing,” says Johnson. This could also apply to stem cells, which are blank slates that can differentiate into any type of cell in the body. Some experiments have shown that the way stem cells differentiate is altered in microgravity. Scientists don’t know why yet, but if they could take advantage of frequent, low-cost research in low Earth orbit, they increase their chances of figuring it out. Since each stem cell is specific to a person, Johnson sees the potential for a bank of stem cells available for you the next time you need a replacement liver. He admits, “This is a little far out, we’re not quite there yet.”

In the few years that NanoRacks has been operating, Jeff Goldstein’s organization has already sent a few dozen experiments to the station. Goldstein is the director of the National Center for Earth and Space Science Education, which posts on its website a row of countdown clocks for its upcoming station launches. The center’s mission is to immerse students—kindergarten through college—in science research, from proposal writing to data analysis. Goldstein had wanted for years to get students doing hands-on space research, but couldn’t find the right fit until NASA signed the Space Act Agreement with NanoRacks. Partnered with NanoRacks, he was able to create a national program. “I relate to them very well,” he says. “We’re a small organization that can turn on a dime, which is absolutely essential. If you see an opportunity, you don’t have to have a committee meeting for six months to do it.” With NanoRacks’ fast turnaround time, the students Goldstein works with can propose an experiment and get it to the station within a single school year.

The center is another beneficiary of NanoRacks’ devotion to customer service. Its experimenters were among the first to use MixStix, a standard NanoRacks offering that operates like a glowstick: The astronaut bends a plastic-enclosed tube until a glass inside breaks, mixing the substances and starting a chemical reaction. When the sticks were returned, some of the students found that their experiments hadn’t been initiated. NanoRacks employees looked into the problem and discovered that although they’d told the astronauts to bend the tubes, they hadn’t explicitly said how far, and some of the tubes had not been bent enough to break the glass.

Johnson says, “The good news is we re-flew the science that didn’t get activated…very quickly, within four to six months,” something that could never have happened in the shuttle era.

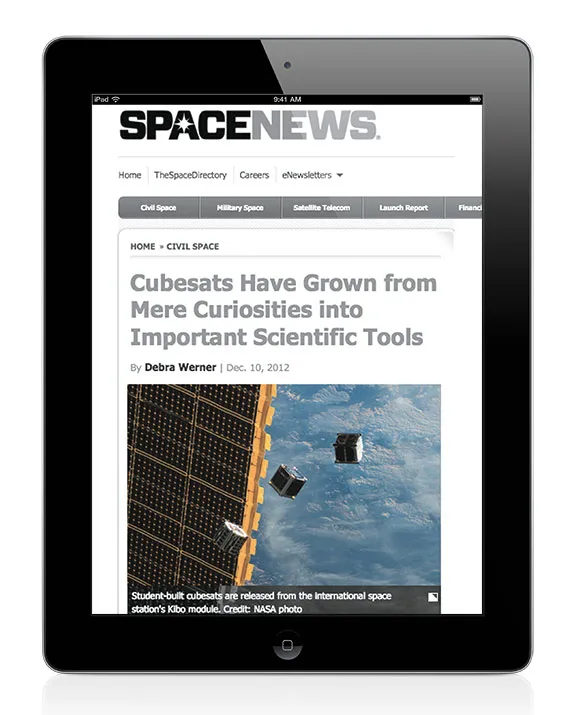

Manber and his colleagues have worked hard to establish their company’s reputation among scientists and educators hoping to do research in microgravity, but to win the small-satellite market, it took only a single photograph. In October 2012, NanoRacks deployed a cubesat—one in a group of three—and the stunning photo of the tiny satellites floating past the station’s solar panels with Earth below hit the Internet. The company’s phones haven’t stopped ringing since.

That has Manber breathing a sigh of relief. “We lost so much money deploying that satellite,” he says. “The NASA safety office was being so careful because it was the first one,” and the first of anything that happens in space requires “safety experts, safety consultants, endless meetings, meetings after meetings after meetings.” But little cubesats can do all the things big satellites do—Earth imaging for environmentalists, surveying for oil and gas companies, communications for soldiers in remote war zones—and now, demand for the service has created a backlog. NanoRacks spent the last year developing a high-volume, spring-loaded launcher that can carry 48 units, designed so that, if need be, 16 launchers can fit in the airlock of the Japanese Kibo module, from which the cubesats are deployed. The company has 34 satellites scheduled for the airlock’s December opening. “I believe it’s a world record in terms of satellites launched at one time,” says Johnson. (The real estate aboard Kibo, as well as the use of the airlock, is part of an exchange that NASA negotiated with station partners during the shuttle era. The space shuttle ferried modules, people, and supplies in return for certain access and services.)

NanoRacks has become part of the rising tide lifting the commercial space industry. “This is what I’ve been waiting for for 25 years,” says Manber. “It’s a wonderful period for space business. We have reached what myself and others have worked for—government is a regulator, a landlord, and not a competitor, but a customer.” Companies no longer have to depend on the few, irregular shuttle launches for transportation to space. “We have multiple access,” he continues. “We’ve had 10 payloads brought down on the Soyuz.”

NanoRacks is helping to stimulate space commerce. The company recently awarded $2,000 in seed funding for a low-cost, open-source NanoLab to Infinity Aerospace. Infinity came up with a sleek, transparent cube form built around a circuit board wired with hundreds of instruments and sensors to choose from. Anyone with $1,999 can buy a one-unit version, select instruments from a menu, and program an experiment. It’s called Ardulab (from Arduino, the name of the circuit board included). If you’re ready to buy, just add it to your cart on Infinity’s website. NanoRacks sent the first Ardulab to the station aboard Orbital Sciences’ Cygnus cargo ship in September.

Another NanoRacks business partner, Nanosatisfi, is an online broker for access to programmable cubesats. For as little as $125, customers can buy time on one of the cubesats that NanoRacks plans to deploy from the station in December.

These armchair mission commanders take online courses to learn how to code instructions to the satellite’s computer, like “Take this image at this location and this time” or “Measure this magnetic field.” When everything is ready, they click the “Deploy to Satellite” button on Nanosatisfi’s website. Nanosatisfi checks the program to make sure it doesn’t do anything dangerous, then transmits it to the satellite. When the customers are notified that the data has been downloaded from the cubesat, they can log in to see it.

Nanosatisfi founder Peter Platzer says that NanoRacks helped “with the massive amounts of paperwork that is required to launch to the ISS. You deliver a satellite to them, they do a whole bunch of tests and certifications for it, and then they deliver it to NASA.” He continues, “Jeffrey [Manber] has not only taken advantage of the breaking of structures, he’s in there taking a crowbar [and] increasing the fissures.”

Today NanoRacks is preparing for its next foray into station research: exposing experiments to the harsh environment of space. The External Platform, being built by Astrium in Houston, Texas, will sit outside the Kibo module within reach of the robotic arm, so changing experiments won’t require spacewalks. Just like the racks inside, the platform will hold the standard cube forms connected through USB ports.

Johnson expects most customers for this service to be satellite manufacturers. The insurers of multimillion-dollar spacecraft generally won’t cover parts that haven’t proved they can withstand space travel. It’s a Catch-22 that inhibits innovation in satellites. With the NanoRacks External Platform, satellite builders can orbit parts and electronics at a low cost. After the parts have been flight-tested, they can be returned for study, something revolutionary in the satellite field.

Now four years old, NanoRacks faces the problem every business hopes for: too many customers. The company had a staff of 12 as 2013 began but plans to have 25 by the end of the year, and, in addition to its Houston headquarters, is expanding its Washington, D.C. office and planning to open a third in Florida. Meanwhile, Jeffrey Manber continues to be an evangelist for the space station. “Space exploration today, by all nations, by all companies, is one of the most extraordinary achievements of humankind,” he says, and yet “there’s no more perfect example of [the space community’s dismal communication to the general public] than the International Space Station.” More people should be using the station, he says, and not just scientists. He’d like artists to do projects there and businessmen who see its potential for entertainment or marketing or other uses besides scientific research. “I think NASA has to relax a little bit,” he says. “The next step is to open up the emotional connection between consumers and this amazing facility in space.”

And the next step for NanoRacks? “I go where the customer demands,” says Manber. That sentiment may not be as grand as an exhortation to explore, but it sounds like good business.

Heather Goss is an associate editor at Air & Space/Smithsonian.