Space Suits Past and Future

Bill Elkins has been outfitting astronauts since before NASA was born.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/elkins-spacesuit-flash.jpg)

Bill Elkins has been called “one of the true fathers of the space suit.” Within months of the Sputnik 1 launch in October 1957, he began working at Wright-Patterson Air Force Base in Ohio on “restraint couches” for astronauts. In the late 1960s, as a chief engineer at Garrett AiResearch, his team outcompeted four established space suit manufacturers to win the NASA contract to build long-endurance lunar suits that were to have flown on Apollos 18, 19, and 20. His suit never made it to the moon, however, because NASA cancelled all landings after Apollo 17 in December 1972.

Since then Elkins, who is in the U.S. Space Foundation’s Space Technology Hall of Fame, has founded several companies. Today, at age 80, he lives outside Sacramento, California, and continues working, having founded bioCOOL Technologies in 2004 and the consulting firm, WElkins in 2007. He spoke recently with Air & Space Associate Editor Mike Klesius.

Air & Space: How did the first astronaut restraint systems compare to jet pilot systems already in use?

Elkins: A jet pilot restraint system has a hard backpan and seat. It mainly is trying to contain the pilot in the seat, in a sitting position. In an astronaut couch you’re lying on your back. [In the late 1950s] they were planning a cast, form-fitting, backpan restraint couch for the astronauts. But in tests at high G it was causing substernal pain, where the sternum of the occupant would compress into the chest. I designed a sophisticated hammock supported by a tubular steel frame. It left your body in a more normal, natural form at high G. The Mercury project was then transferred to NASA and I lost track of that research. In the end, they went with the harder, backpan restraint couch.

A&S: You once sustained 16.5 Gs, an apparent record for pulling Gs and remaining conscious.

Elkins: We were examining a worst-case G scenario for a Mercury launch. So they put me in the 20-foot-arm centrifuge at Wright-Pat. The G profile was based on the maximum G that could be experienced during the launch. If the escape rocket was fired at maximum dynamic pressure—Mach 1 at roughly 40,000 feet—then 15.5 G would be experienced by the astronaut. So we [added] one G…and “flew” it on the centrifuge. The whole run duration was about three minutes. I began to gray out a bit at 13 G. Then I was above 15.5 G for about six seconds. I “flew” a tracking task with my right hand, and I had a button I could press with my left hand to respond to peripheral lights. I recently discussed this matter with Jim Brinkley, who was contemporary with me at Wright-Patterson. He became the head of the Biodynamics Lab and is an internationally recognized biodynamicist. He confirmed, to the best of his knowledge, that the 16.5 sustained G remains a benchmark achievement. They shut down that centrifuge for good not long after we did those runs in December 1958. We burned it out, I guess.

A&S: How did you get into designing space suits?

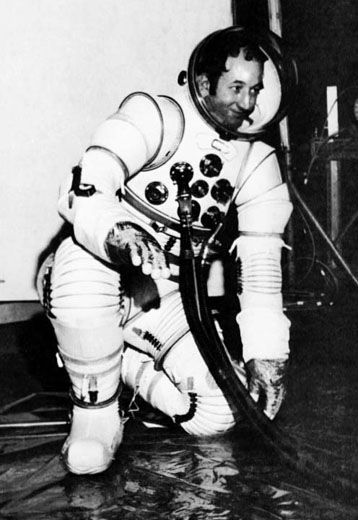

Elkins: Those runs are what got me into the spacesuit world, first at Litton where I developed the RX (rigid experimental) series of suits, and then at AiResearch, where, in about two years, I became chief engineer and developed the EX-1A and the AES [Advanced Extravehicular Suit] that won the competition for the extended Apollo mission suit.

Early on, a physicist at Litton was developing a vacuum chamber pressure suit, but Litton thought they were causing permanent heart damage. I had miles of EKGs from my centrifuge runs, so I had a certified healthy heart and was chosen as the test subject to verify or deny the problem. The lab they brought me to was in Beverly Hills, California, of all places. For lunch that day, at a local deli, I made the mistake of ordering a corned beef sandwich with the hottest mustard they had, and shortly before the test began, I started getting some serious heartburn. Well, they put me in a pressure chamber and took me up to 400,000 feet equivalent. The doctor asked me how I was feeling, and I said, “Fine, but I’m feeling a little heartburn.” He said, “Lay back!” and made me swallow a nitroglycerin pill. A subsequent conference of heart specialists determined there was no problem with the vacuum chamber suit.

A&S: What’s the biggest challenge in designing an effective space suit?

Elkins: Well, a big one is mobility, specifically the joints. If you look at the Apollo [suit] joints, the farther you bent them, the more effort it took and the harder it was to hold that position. Those suits were spring loaded to come back to the neutral position. So it took a constant force to keep them out of neutral, and that was very fatiguing. But when you move a constant volume joint to a new position, no further force is needed. When I left Litton and went to AiResearch, I invented the toroidal joint. Toroids maintain constant volume so long as the centerline remains constant. At AiResearch I designed the EX-1A [suit], the first prototype suit to use toroidal joints, in 1967. It was an outstanding suit.

A&S: What were the advantages of the hard suit versus the soft suit? Why two totally different kinds?

Elkins: There are some advantages of the hard suit, although I did not remain a proponent of it. The hard suit had value for being able to go to much higher pressures. The higher you go, the less likely you are to have the bends when exiting a higher-pressure space vehicle. So if you were wearing one, you could scramble to do an emergency [spacewalk] because you didn’t have to pre-breathe for four hours. It’s a very mobile little spaceship, if you will. Vic Vykukal, a NASA Ames engineer, also did pioneering work on the hard suit. Although it demonstrated excellent mobility, it was heavier because of the hard structural components, and the joints did not exhibit the long-life capability of the toroidal joint.

The soft suit came from a line of pressure suits used by the Air Force and Navy. BF Goodrich’s soft suits for the Mercury project were evolved from a Navy pressure suit. David Clark made soft suits for Gemini. Then ILC came into the Apollo program. They all came from that same soft emergency pressure suit lineage. It was a question of cultures and politics within the R&D labs. There was the West Coast technology such as Litton, and NASA’s Ames Research lab; but then the older timers from the East who knew soft suits. Ultimately, soft suits won out.

A&S: It’s often pointed out that the moon suits were so heavy. What was the single heaviest element?

Elkins: I think it was the PLSS, portable life support system [backpack]. The suit by itself would weigh about 60 pounds.

A&S: What was driving the desire for design changes in lunar suits for the extended Apollo missions?

Elkins: They had to be different from the earlier Apollo suits because the lunar rovers would carry astronauts some distance away from the lunar lander. They wanted to explore interesting geological features on the moon. NASA wanted a suit that, should the rover fail, had the mobility for the astronaut to quickly traverse back to the lunar module.

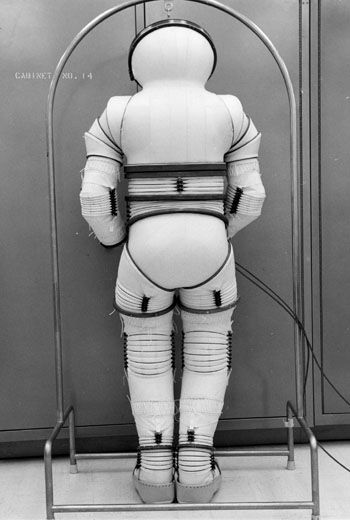

Apollo 16 and 17 used the ILC A7L suit that was not much of an improvement over the previous Apollo suit. In the competition for the extended Apollo missions, the AES was the first truly high mobility suit. It had about 95 percent of nude mobility range. It had significantly greater lifecycle capability. I don’t remember, but I believe the [target length for a lunar stay] was about eight days.

A&S: It’s interesting to see that so much of Constellation, such as the shape of the crew capsule, the composition of the heat shield, the launch abort system, etc., is almost identical in their general design to what was used on Apollo. It appears we figured a lot out the first time around. Will the same be true of the suits?

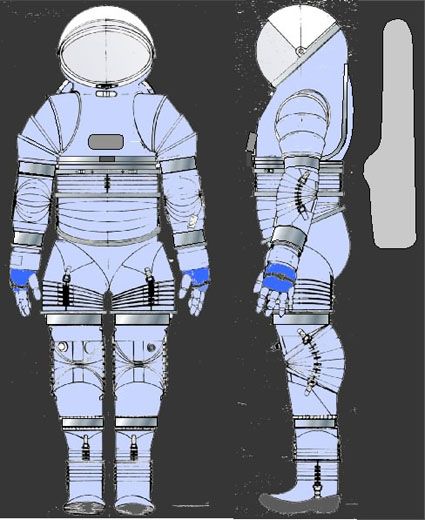

Elkins: Well I’m hoping to influence that. I hope to work with Oceaneering International [a NASA contractor for the Constellation lunar suits]. I have a concept for an EVA [extravehicular activity] suit with some pneumatic restraints. I think elements might apply to Constellation. It’s already applied to a host of applications in the medical field in liquid cooling and pressurization for MS and epilepsy and head trauma patients.

A&S: How will the new suits handle the damaging lunar dust?

Elkins: Good question. I have some concepts. I’m in the beginning stages of some ideas on electrostatic solutions to dust. One of the suits I studied for Lockheed was for doing polar [Earth] orbits, in which you’re introduced to more radiation than with east-west orbits. I came up with the idea of using high density tungsten fabric to increase radiation protection. Tungsten is highly conductive electrically, but still flexible. That high conductivity woven fabric with an electrostatic charge might repel lunar dust.

A&S: What do you think of the proposed suit that would attach its back entry to the outside of a moon base? After a moonwalk, the astronaut exits the suit to enter the base.

Elkins: I’m not a great proponent of the rear entry arrangement. It’s heavy, and uses valuable real estate that interferes with full mobility. My philosophy is to allow the human to operate as the magnificent machine it is. Back door entry does not easily allow for a two-axis waist joint, and that’s especially risky in unprepared terrain. Almost any maneuver you do, you’re unconsciously using your waist. I doubt that you can make the back door entry suit with the waist joint. Furthermore, there would be maintenance issues. Eventually you’ll need to replace components. So you’ll need access to the suits. For me, the human body is an engineering marvel that took several million years to develop. I want the pressure envelope over that body to exhibit the same mobility. That would minimize learning time in using the suit, and allow rapid solutions to problems during [spacewalks].

A&S: The old Apollo suits were used for one mission and retired. How will the new suit be built to handle repeated use?

Elkins: It will have to have a three-million-cycle life, minimum. One bend in one direction, and returning to neutral, that’s one cycle. The Apollo suit joints, and the latest shuttle suit joints, are not much good above 60,000 cycles.

A&S: What drives you to continue your work?

Elkins: I’m 80, and I’m still pretty much working around the clock. If I can contribute to mankind, space, medicine, and other-life hazardous protective applications, it keeps me young.