Test-Driving the Lunar Rover

Before it went to the moon, this spacecraft on wheels had to be put through its paces on Earth.

:focal(2028x1267:2029x1268)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/34/e7/34e72cc2-7408-4816-a147-257a1362c9c7/16b_jj2017_as15-86-11603orig_live.jpg)

The first off-world road trip took place on July 31, 1971, when Apollo 15 astronauts David Scott and James Irwin jumped into their Lunar Roving Vehicle and took off across the moon’s surface at a blistering 2 mph.

The “moon buggy” enabled astronauts to explore more of the moon’s surface; during their mission, Scott and Irwin traveled 17 miles, far more than previous astronauts, who were limited to short walks around their landing sites.

Today, a lunar rover test vehicle—almost identical to the vehicles that went to the moon on three Apollo flights—is parked in the National Air and Space Museum. Although it’s a car, it isn’t out of place among the Museum’s historic air- and spacecraft. “It is, in the truest sense, a spacecraft on wheels,” said Eugene Cowart, Boeing’s chief engineer on the project, in 1973.

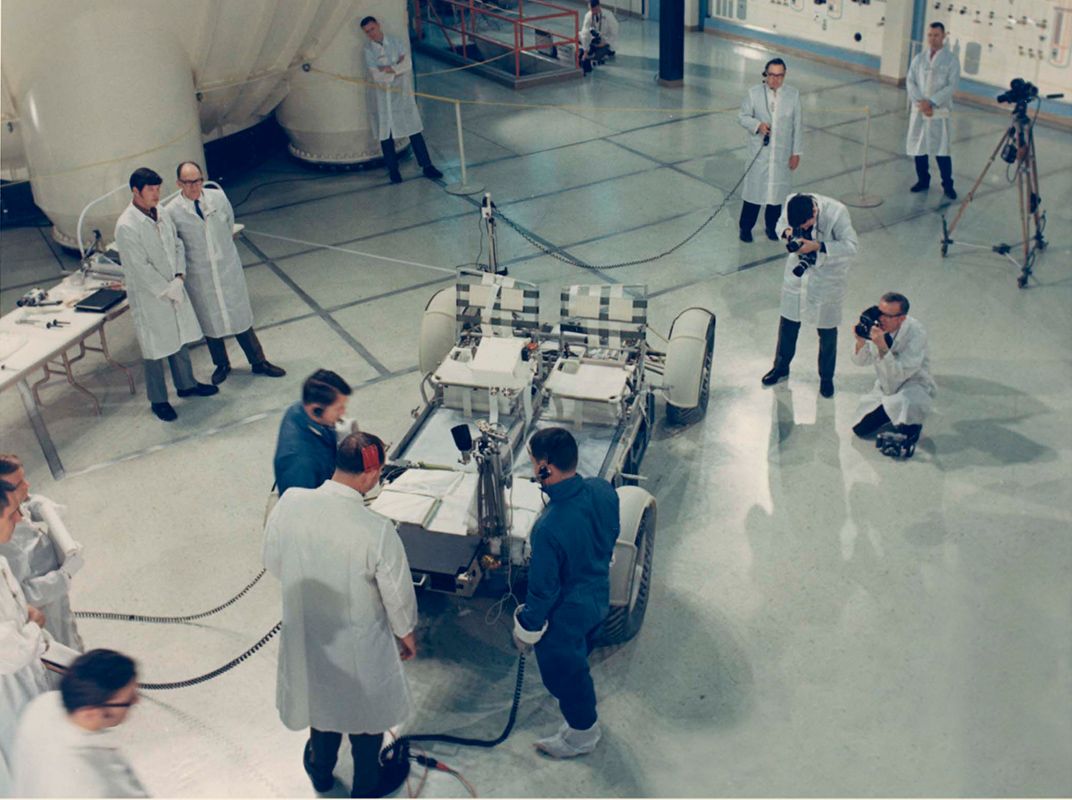

Many of the rovers underwent testing designed to simulate the shocks of liftoff and lunar landing. Boeing was selected to build the rover, in part because its Environmental Test Laboratories in Kent, Washington, could simulate the rigors of spaceflight and the complex lunar environment. There, in the 18-24 Building, Boeing performed extensive “shake and bake” tests on the lunar car.

Since Apollo 15’s three days on the moon would take place during the “lunar morning,” parts of the rover would be heated to as high as 250 degrees Fahrenheit. With no atmosphere to trap heat, however, the moon could also get frigid; some parts of the vehicle in the lunar shadows would be exposed to sub-zero temperatures.

Boeing simulated these conditions in Space Chamber A—a large thermal vacuum chamber—and ran simulated missions with the test rover. Albert Lunde, a former Boeing engineer and manager, explains that as pumps sucked the air from the chamber to create a vacuum, liquid-nitrogen-filled tubes that worked like giant refrigerator coils chilled the chamber walls to -320 degrees, creating the frigid temperature of lunar shade.

Then Boeing turned on the sun: high-intensity xenon arc lamps in the chamber’s ceiling. In one test, the rover spun its wheels for 78 hours to simulate sorties it would make on the moon. Tests were also performed to make sure a rough landing would not affect the ability of the rover—inside the lunar module’s storage bay—to unfold and deploy. In March 1971, the rover was sent to Grumman Aerospace in Bethpage, New York. It was folded and stowed in the storage bay of a test lunar module, which was dropped to simulate a hard landing.

While the test vehicles provided engineers with valuable data on how the rover would withstand liftoff and landing, NASA still needed to figure out how the moon buggy would handle on the moon’s surface. So NASA built a trainer as an astronaut drivers’ ed car. (The trainer, part of the Museum’s collection, is currently on loan to Space Center Houston.)

Because the flight rovers and qualification units were designed to operate in lunar gravity—one-sixth of Earth gravity—structurally, they couldn’t support the astronauts’ weight on Earth. To make the trainer’s chassis testable on Earth, it was made six times stronger than the actual flight unit. Astronauts practiced driving it on what they called the “rock pile,” a simulated lunar surface at the Kennedy Space Center in Florida. At the Manned Spacecraft Center in Houston, Texas, they took a spin in the trainer while it was suspended by cables and cylinders that removed five-sixths of the vehicle’s weight to simulate driving in lunar gravity. Neither scheme precisely captured the experience of driving on the moon. In his 2004 biography, David Scott recalls that “the reduced gravity and very irregular surface [of the moon] meant one or more of the independently suspended wheels lifted away from the surface every time we hit uneven terrain…. It all made for a ride like a cross between a bucking bronco and a small boat in a heavy swell.”

NASA finished shaking, freezing, frying, and dropping the test rover in 1972, and three years later transferred it to the National Air and Space Museum.

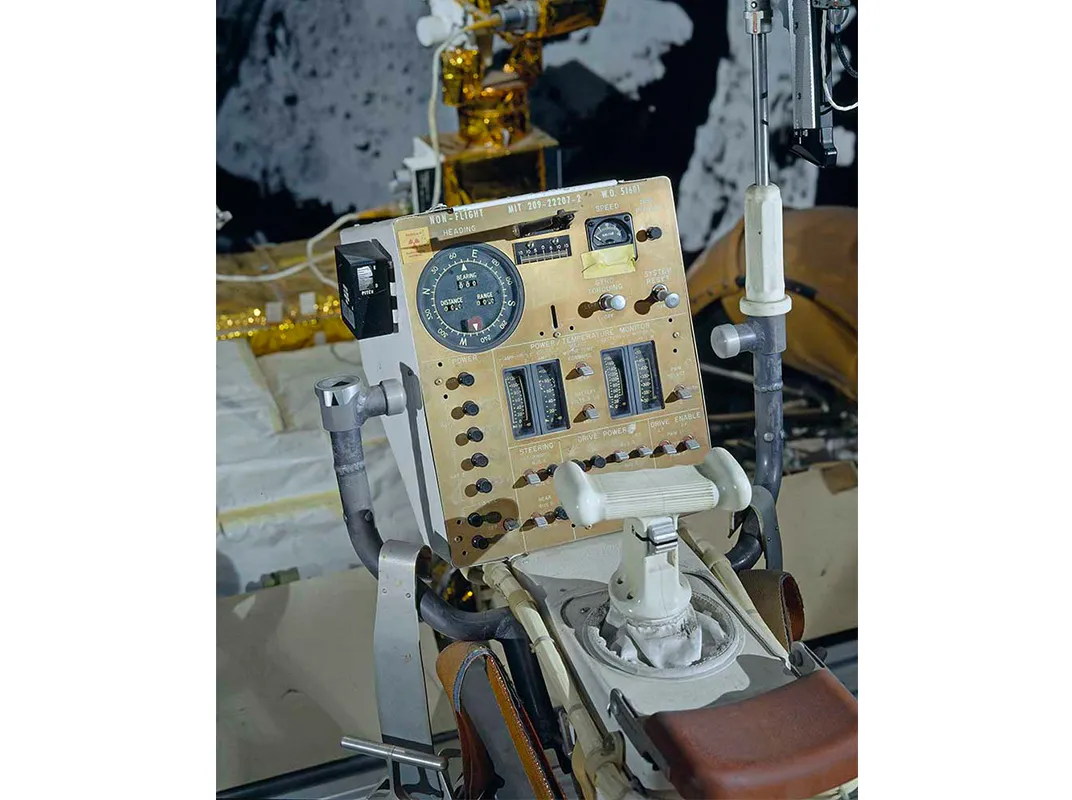

Labels and instruments on the Control and Display Console—the dashboard—of the lunar rovers glowed with radioluminescent paint so astronauts could read them in the dark lunar shadows. The test units’ dials used the same paint, which contained small amounts of radioactive promethium-147. Because of that substance, space history curator Allan Needell explains, the Museum had to take some unusual steps to display the rover. “For many years, we had to carry the rover on our Radiation Safety List and get a license from the Nuclear Regulatory Commission,” he says.Until the radiation intensity dropped to a level specified by the commission, visitors had to be kept three feet away from the vehicle.

The rovers that revolutionized lunar exploration on the Apollo 15, 16, and 17 missions had to be left behind at the Hadley-Apennine, Descartes Highlands, and Taurus-Littrow landing sites, respectively. It’s a much shorter and easier trip to see their identical understudy, the LRV Qualification Test Unit, in the Museum’s exhibit, “Apollo to the Moon.”